Marine-derived high temperature lipase as well as crystals and preparation method thereof

A lipase and source technology, applied in the field of enzyme engineering, can solve problems such as not being able to fully meet the needs of production practice, and achieve broad market prospects and application potential, high efficiency and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

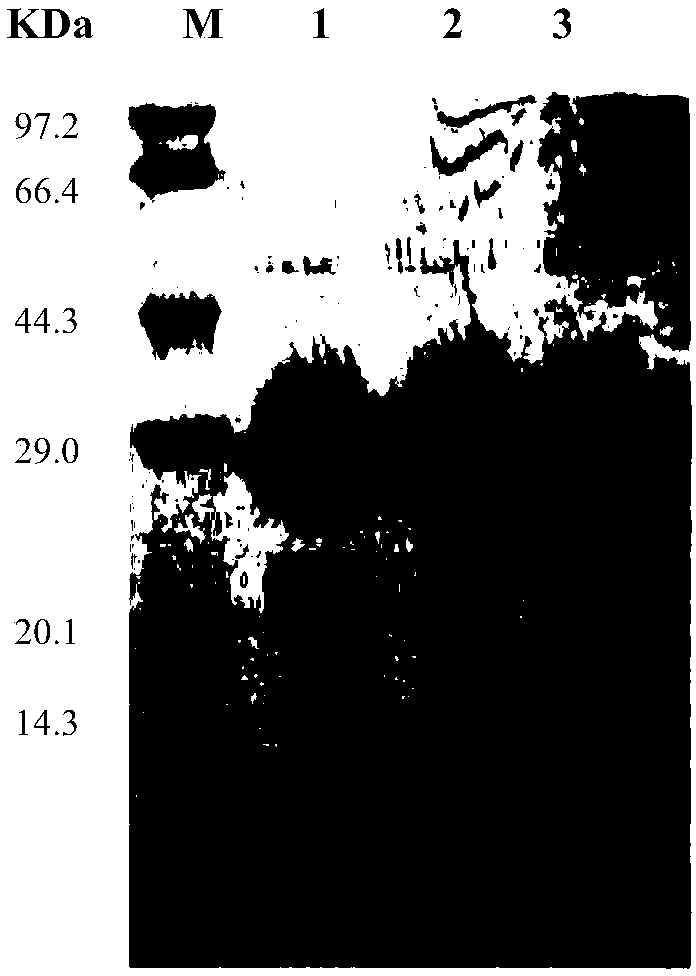

[0034] Example 1 Expression and purification of marine-derived high-temperature lipase SL1

[0035] Preparation of crude enzyme solution of marine-derived high-temperature lipase SL1: clone the gene sequence of marine-derived high-temperature lipase SL1 into the pET22b(+) prokaryotic expression vector and transform the vector into Escherichia coli competent cells Rosetta (DE3). Into a 5 mL test tube of LB medium containing 1 mM ampicillin (Amp) was added the cryopreserved glycerol bacterium liquid of the above-mentioned transformant at an inoculation amount of 5%, and cultured overnight at 37° C. with constant temperature and shaking. Then inoculate the above seed liquid into 100 mL LB medium containing 1 mM ampicillin, and culture at 37° C. at 200 rpm until the absorbance at 600 nm of the bacterial suspension is 0.8. Add isopropyl-β-D-thiogalactopyranoside (IPTG) inducer to a final concentration of 0.2mM, and induce at 20°C for 16h. Centrifuge at 4500r / min at low temperature...

Embodiment 2

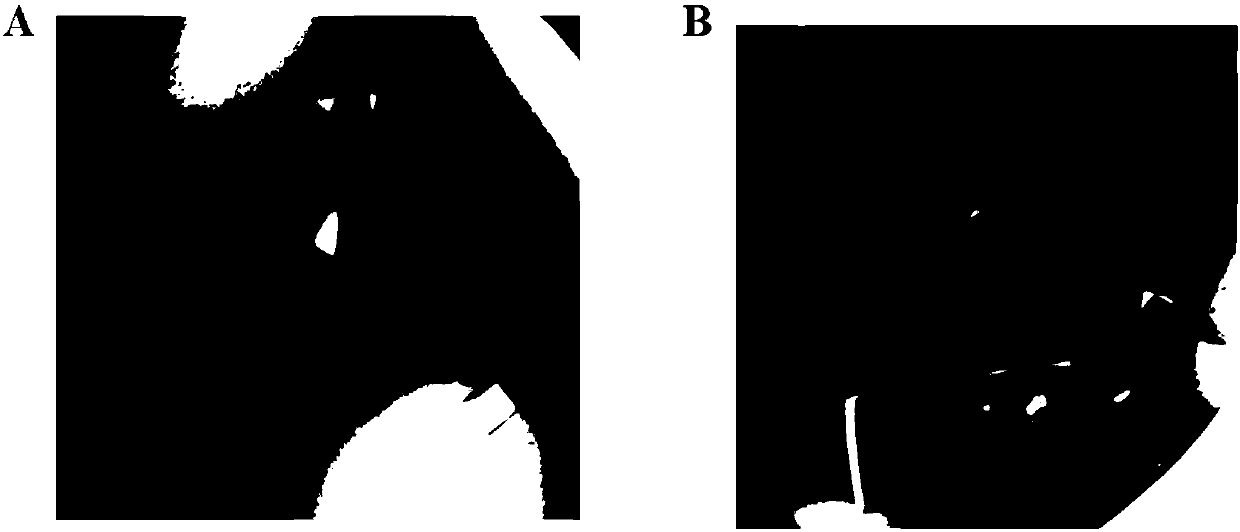

[0038] Example 2 Crystal preparation of marine-sourced high-temperature lipase SL1

[0039] The crystal growth of high-temperature lipase SL1 from marine sources was accomplished by the sitting drop method of vapor diffusion (Vapor Diffusion). Four kinds of protein crystallization kits including Crystal Screen2, Index (sparse matrix screening), SaltRx (different pH buffer environments and salts) and PEG / Ion (screening of different polymers, salts and pH buffer environments) from HamptonResearch were used for protein crystallization. Screening conditions for crystallization. Add 50 μL of the crystallization buffer in each crystallization kit to the corresponding lower groove of the 96-well plate. Use a robot arm to mix 1 μL of protein with 1 μL of buffer in the lower tank, seal the 96-well sitting drop plate with a sealing film, and let it stand at 15-25°C with constant temperature and humidity.

[0040] Optimization of crystallization conditions: After the crystals grow out,...

Embodiment 3

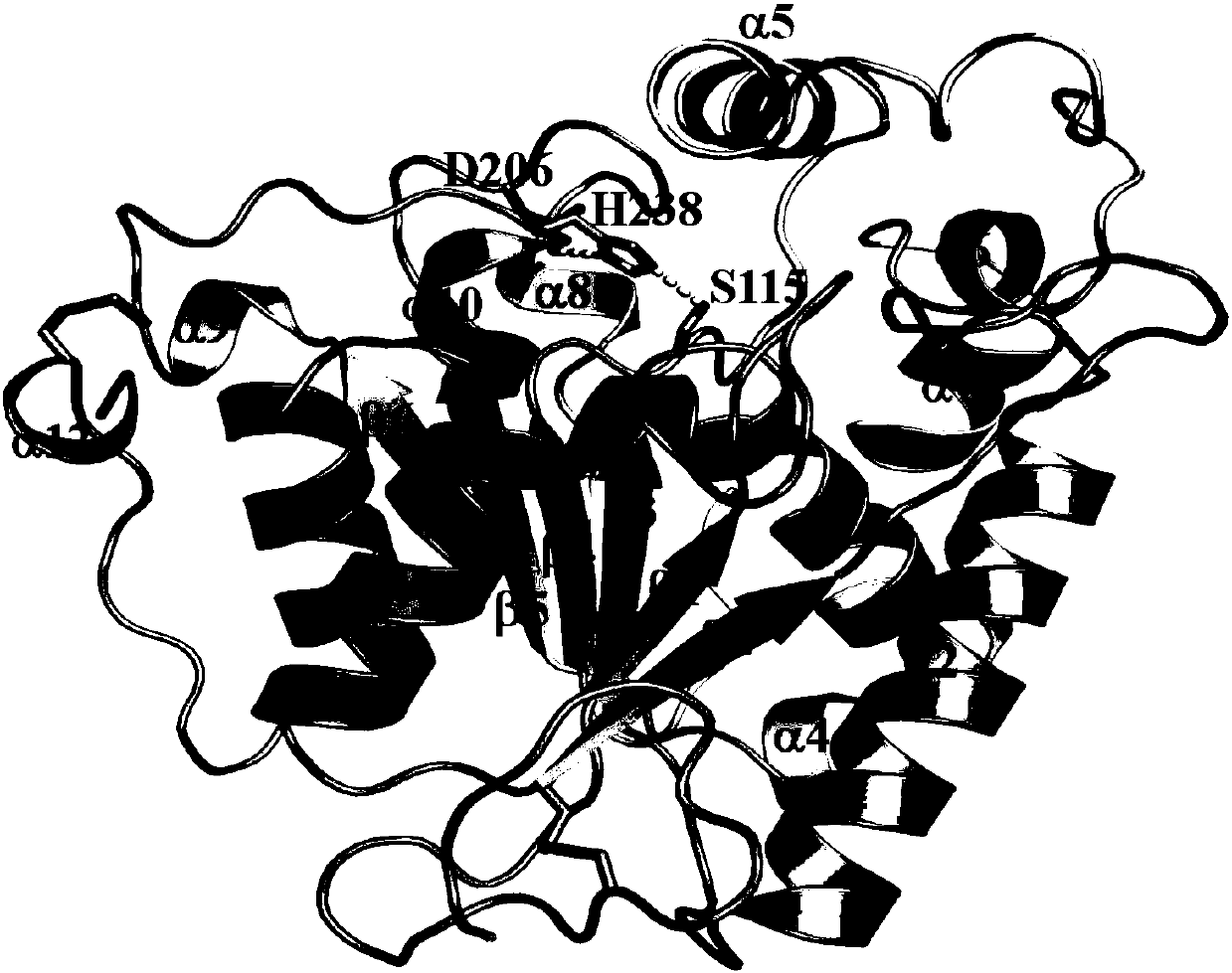

[0044] Example 3 Identification of biochemical and catalytic properties of high-temperature lipase SL1 from marine sources

[0045] Effect of temperature on enzyme activity: using emulsified olive oil as a substrate, the hydrolysis activity of high-temperature lipase SL1 from marine sources was measured at 50-90°C. The reaction system was mixed with 4 g of emulsified olive oil (olive oil: polyvinyl alcohol = 1:3) and 5 g of 0.1 M pH 7.0 phosphate buffer, and pre-incubated at a specific temperature for 10 min. Add 1mL of enzyme solution, react for 15min, and terminate the reaction with 15mL of 95% ethanol; use phenolphthalein as indicator, and titrate the released fatty acid with 0.05M KOH. High temperature inactivated enzymes were used for control experiments. The optimal reaction temperature range of marine high-temperature lipase SL1 is about 70°C, so it can be judged that the lipase is a high-temperature enzyme.

[0046] Esterification of oleic acid and glycerol: The prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com