A kind of anti-salt and anti-high temperature foaming agent and preparation method thereof

A technology of high temperature resistance and foam discharge agent, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problem of large amount of surfactant and microbial fermentation broth, large amount of microbial fermentation broth and surfactant, and environmental hazards. and other problems, to achieve the effect of improving the efficiency of drainage and gas recovery, improving the effective permeability and improving environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

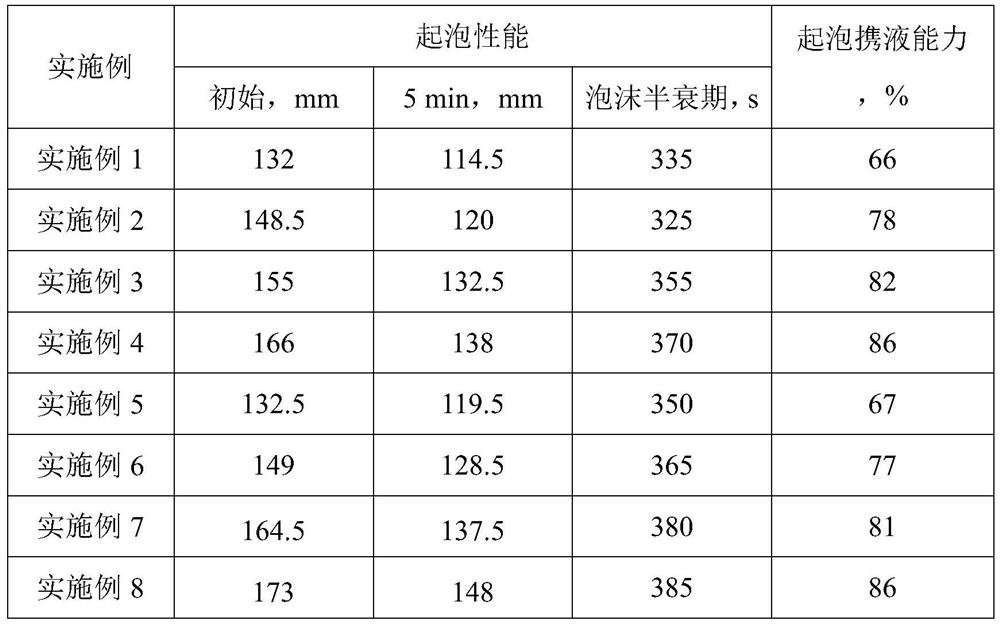

Examples

Embodiment 1

[0050] The anti-salt and anti-high temperature foaming agent of the present embodiment is composed of the following components in mass percentage: 0.2% of anion-nonionic surfactant composite system, 0.02% of Pseudomonas aeruginosa fermentation broth producing glycolipid biosurfactant %, the balance is water; wherein the anion-nonionic surfactant complex system consists of anionic surfactant sodium dodecylbenzenesulfonate and nonionic surfactant fatty alcohol polyoxyethylene ether AEO 9 according to the quality of 30:70 Than mixed to get.

[0051] The preparation method of the anti-salt and anti-high temperature foaming agent of the present embodiment comprises the following steps:

[0052] 1) Pseudomonas aeruginosa (Pseudomonas aeruginosa) CGMCC No.1.2464 was inoculated on LB solid medium, and cultured at 35°C for 3 days to form colonies; the LB solid medium was: agar powder 15g / L, peptone 12g / L, yeast powder 3g / L, NaCl 12g / L, add water to 1L, pH 7;

[0053] 2) The single b...

Embodiment 2

[0057] The anti-salt and anti-high temperature foaming agent of the present embodiment is composed of the following components in mass percentage: 0.3% of anion-nonionic surfactant composite system, 0.04% of Pseudomonas aeruginosa fermentation broth producing glycolipid biosurfactant %, the balance is water; wherein the anion-nonionic surfactant complex system is composed of anionic surfactant α-olefin sulfonate sodium and nonionic surfactant alkylphenol polyoxyethylene ether TX-40 according to the quality of 50:50 Than mixed to get.

[0058] The preparation method of the anti-salt and anti-high temperature foaming agent of the present embodiment comprises the following steps:

[0059] 1) Pseudomonas aeruginosa (Pseudomonas aeruginosa) CGMCC No.1.2464 was inoculated on LB solid medium, and cultured at 37°C for 2 days to form colonies; the LB solid medium was: agar powder 20g / L, peptone 8g / L L, yeast powder 5g / L, NaCl 8g / L, add water to 1L, pH 8;

[0060] 2) The single colony...

Embodiment 3

[0064] The anti-salt and anti-high temperature foaming agent of the present embodiment is composed of the following components in mass percentage: 0.4% of anion-nonionic surfactant composite system, 0.06% of Pseudomonas aeruginosa fermentation broth producing glycolipid biosurfactant %, the balance is water; wherein the anionic surfactant complex system is composed of anionic surfactant N,N-oleoyl methyl taurate sodium and nonionic surfactant polyoxyethylene amide 6503 according to the ratio of 70:30 The mass ratio is obtained by mixing with water.

[0065] The preparation method of the anti-salt and anti-high temperature foaming agent of the present embodiment comprises the following steps:

[0066] 1) Pseudomonas aeruginosa (Pseudomonas aeruginosa) CGMCC No.1.2464 was inoculated on LB solid medium, cultured at 42°C for 1d, and colonies were formed; the LB solid medium was: agar powder 18g / L, peptone 10g / L , Yeast powder 4g / L, NaCl 10g / L, add water to 1L, pH 7;

[0067]2) T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com