Preparation method of 1-bromoethyl acetate

A technology of bromoethyl acetate and vinyl acetate, which is applied in the field of preparation of 1-bromoethyl acetate, can solve problems such as uncontrollable reaction, uncontrollable reaction, and increased impurities, so as to avoid production equipment and operation The effect of high protection requirements, mild reaction conditions, and easy separation and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation of nano ferric oxide:

[0046] 1) Divalent iron salt (FeSO 4 ·7H 2 O) and ferric salt (FeCl 3 ·6H 2 O) after mixing according to the mol ratio of 2:3, add pure water, make the iron salt total concentration be 0.6mol / L;

[0047] 2) Adjust the temperature to 45°C, and slowly add ammonia water while stirring until the pH of the solution is 9;

[0048] 3) Add surfactant sodium dodecylbenzene sulfonate and stir vigorously for 60 minutes, wherein the amount of surfactant is 10% of the amount of ferrous salt;

[0049] 4) After settling with a magnet, let it stand for 5 minutes, take the precipitate, and wash the precipitate alternately with pure water and absolute ethanol until the pH of the washing water is neutral;

[0050] 5) Dry the precipitate in an oven for 5 hours to obtain nanometer ferric oxide.

[0051] The prepared nano iron ferric oxide has superparamagnetism and water insolubility, and the particle diameter is 250-300nm.

Embodiment 1

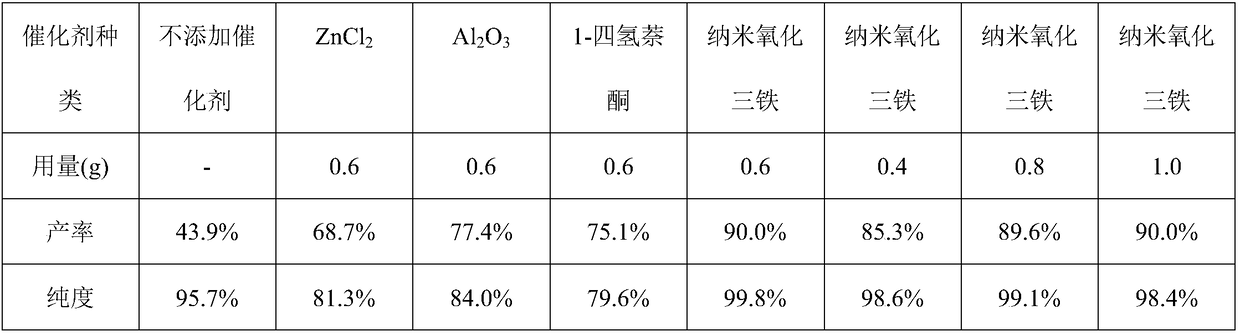

[0053] Add 40.6 mL of pure water and 0.4 g of nanometer ferric oxide to a reaction flask equipped with a mechanical stirrer, keep the temperature at 6°C, add 145 mL of silicon tetrabromide after stirring for 3 minutes, and slowly add 377 mL of vinyl acetate after stirring for 5 minutes, Adjust the temperature to 15°C, and finish the reaction after a period of reaction; use a magnet to separate the nano-ferric oxide from the mixed solution after reaction, and then pass the mixed solution through a 0.22 μm organic filter membrane to remove solid impurities; cool the mixed solution to Keep at 4°C, add 100mL of extractant to it, stir for 15min, add 30mL of pure water, stir for 5min, let stand for 5min, take the organic phase, add 40mL of pure water and stir for 5min, let stand for 5min, take the organic phase for vacuum distillation, remove Distillation, that is, the product 1-bromoethyl acetate. Wherein the extractant is a mixture of dichloromethane and chloroform with a volume r...

Embodiment 2

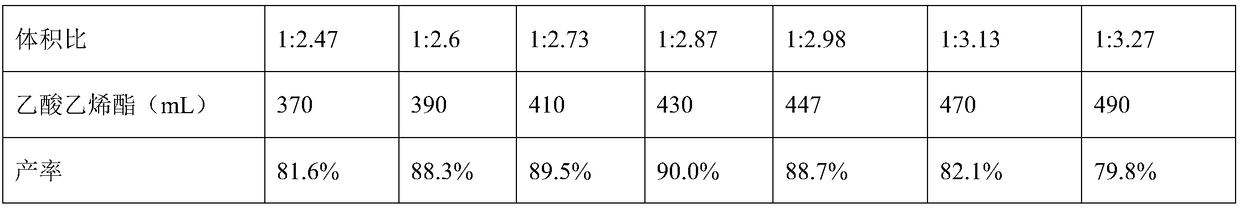

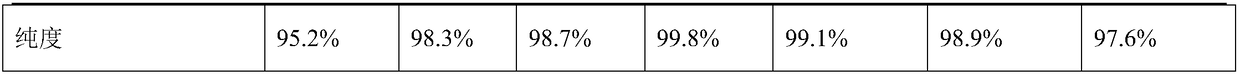

[0057] Add 54.0mL of pure water and 0.6g of nanometer ferric oxide to a reaction flask equipped with a mechanical stirrer, keep the temperature at 6°C, add 150mL of silicon tetrabromide after stirring for 5 minutes, slowly add vinyl acetate after stirring for 5 minutes, and The temperature was adjusted to 15°C, and the reaction was completed after 40 minutes of reaction; the nano-ferric oxide was separated from the reacted mixed solution with a magnet, and then the mixed solution was passed through a 0.22 μm organic filter membrane to remove solid impurities; the mixed solution was cooled to 4°C and Keep, add extractant 100mL to it, stir for 15min, add pure water 30mL, stir for 5min, let stand for 5min, take organic phase, add pure water 40mL and stir for 5min, let stand for 5min, take organic phase and distill under reduced pressure, remove distillate, namely The product 1-bromoethyl acetate was obtained. Wherein the extractant is a mixture of dichloromethane and chloroform w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com