Special fertilizer for orychophragmus violaceus and production method thereof

A technology of special fertilizer and special fertilizer, which is applied in Eryuelan special fertilizer and its production field, can solve the problems of low utilization rate of fertilizer nutrients in the current season, ignoring the application of organic fertilizer and micro-fertilizer, economic loss and environmental pollution, and achieve the cost of fertilization Low, simple processing and application process, reducing the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

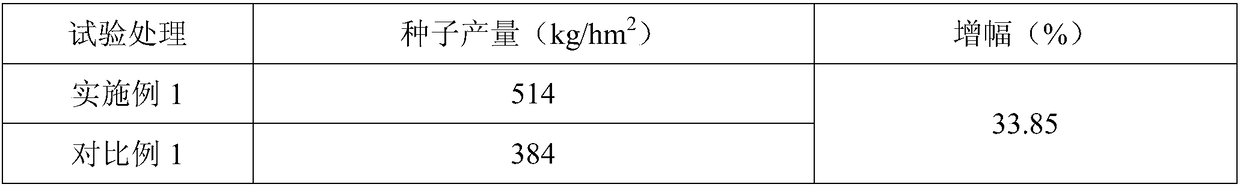

Embodiment 1

[0040] Components (parts by mass): 27 parts of urea, 8 parts of potassium sulfate, 30 parts of humic acid chelated slow-release fertilizer, 25 parts of weathered coal, and 10 parts of bentonite.

[0041] The preparation method is as follows:

[0042] (1) Preparation of humic acid chelated slow-release fertilizer: 36 parts by mass of weathered coal, 50 parts by mass of dipotassium hydrogen phosphate, 10 parts by mass of ammonium bicarbonate, 2 parts by mass of boric acid, 0.5 parts by mass of zinc sulfate heptahydrate, 1 mass part 1 part of ferrous sulfate heptahydrate and 0.5 part by mass of manganese sulfate are pulverized to a particle diameter of 0.1-0.3mm; the above raw materials are evenly mixed, sealed and reacted for 36-48 hours, and then air-dried until the water content is below 20% to obtain humic acid chelated slow-release Fat.

[0043] (2) Preparation of Eryuelan special fertilizer: pulverize weathered coal, bentonite, urea, potassium sulfate and humic acid chelat...

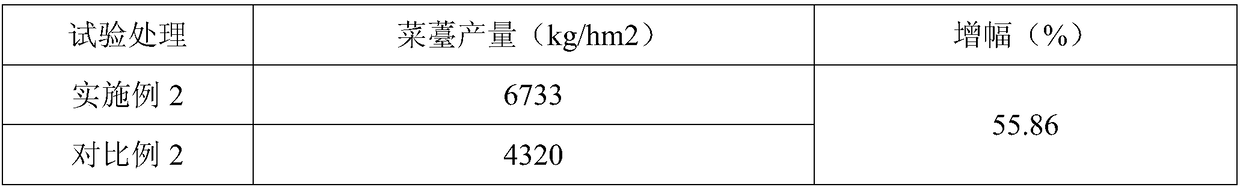

Embodiment 2

[0046] Components (parts by mass): 22 parts of urea, 13 parts of potassium sulfate, 20 parts of humic acid chelated slow-release fertilizer, 35 parts of weathered coal, and 10 parts of bentonite.

[0047] The preparation method is as follows:

[0048] (1) Preparation of humic acid chelated slow-release fertilizer: 37.5 parts by mass of weathered coal, 50 parts by mass of dipotassium hydrogen phosphate, 10 parts by mass of ammonium bicarbonate, 1 part by mass of boric acid, 0.5 parts by mass of zinc sulfate heptahydrate and 1 mass part Ferrous sulfate heptahydrate is pulverized to a particle diameter of 0.1-0.3 mm; the above-mentioned raw materials are uniformly mixed, sealed and reacted for 36-48 hours, and then dried to a water content below 20% to obtain a humic acid chelated slow-release fertilizer.

[0049] (2) Preparation of Eryuelan special fertilizer: pulverize weathered coal, bentonite, urea, potassium sulfate and humic acid chelated slow-release fertilizer until the p...

Embodiment 3

[0052] A kind of Er Yue Lan special fertilizer, with organic matrix, inorganic matrix, nitrogen fertilizer, potassium fertilizer, humic acid chelated slow-release fertilizer as basic raw materials, the mass parts of each component are: 22 parts of urea, 6 parts of potassium sulfate, humic acid chelate 20 parts of slow-release fertilizer, 42 parts of weathered coal, and 10 parts of bentonite.

[0053] The preparation method is as follows:

[0054] (1) Preparation of humic acid chelating slow-release fertilizer: 38 mass parts of weathered coal, 50 mass parts of dipotassium hydrogen phosphate, 10 mass parts of ammonium bicarbonate, 1 mass part of boric acid and 1 mass part of ferrous sulfate heptahydrate are pulverized to The particle diameter is 0.1-0.3 mm; the above raw materials are uniformly mixed, airtightly reacted for 36-48 hours, and then dried until the water content is below 20%, so as to obtain the humic acid chelated slow-release fertilizer.

[0055] (2) Preparation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com