Naphthalene-rich liquid based on single-layer porous titanium dioxide modified aluminium oxide catcher

A technology of porous titanium dioxide and alumina, which is applied in the field of naphthalene separation, can solve problems such as immature separation technology and affect product purity, achieve good trapping effect, increase specific surface area and sensitivity, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

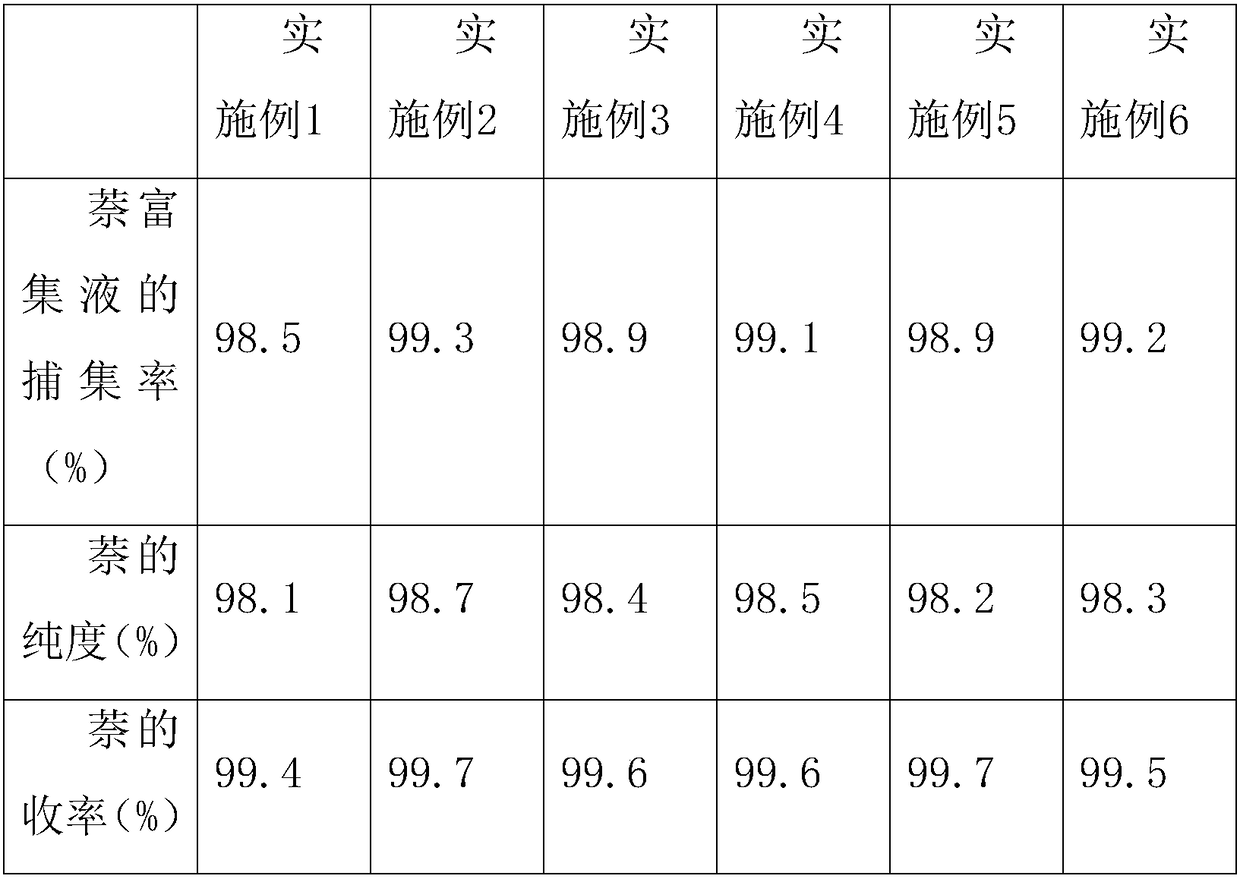

Examples

Embodiment 1

[0027] (1) Add aluminum hydroxide powder into water, mix evenly, add it into a high-pressure reactor with a polytetrafluoroethylene liner, conduct a hydrothermal reaction at 140°C for 3 hours, take it out and dry it to obtain pretreated aluminum hydroxide crystals, Then place it in a vacuum environment and decompose at 950°C for 1 hour to obtain flaky alumina powder.

[0028] (2) adding flake aluminum oxide powder to the titanium-containing precursor solution, wherein the components in the titanium-containing precursor solution include: 5wt% triblock polymer F127, 10wt% butyl phthalate , 0.6wt% hydrochloric acid and solvent, containing the tetrahydrofuran solution of ethanol / glycerol with a volume ratio of 75:5 in the solvent, after stirring evenly, transferred to a high-pressure reactor with a polytetrafluoroethylene liner, at 120 ° C Under hydrothermal reaction for 1 hour, alumina powder coated with titanium dioxide coating was obtained.

[0029] (3) Put the alumina powder ...

Embodiment 2

[0033] (1) Add aluminum hydroxide powder into water, mix evenly, add it into a high-pressure reactor with a polytetrafluoroethylene liner, conduct a hydrothermal reaction at 160°C for 6 hours, take it out and dry it to obtain pretreated aluminum hydroxide crystals, Then put it in a vacuum environment and decompose it at 1200°C for 3 hours to obtain flaky alumina powder.

[0034](2) Add flake aluminum oxide powder to the titanium-containing precursor solution, wherein the components in the titanium-containing precursor solution include: 8wt% triblock polymer F127, 15wt% butyl phthalate , 0.9wt% hydrochloric acid and solvent, containing the tetrahydrofuran solution of ethanol / glycerol with a volume ratio of 80:15 in the solvent, after stirring evenly, transferred to a high-pressure reactor with a polytetrafluoroethylene liner, at 140 ° C Under hydrothermal reaction for 4 hours, alumina powder coated with titanium dioxide was obtained.

[0035] (3) Put the alumina powder coated ...

Embodiment 3

[0039] (1) Add aluminum hydroxide powder into water, mix evenly, add it into a high-pressure reactor with a polytetrafluoroethylene liner, conduct a hydrothermal reaction at 150°C for 4 hours, take it out and dry it to obtain pretreated aluminum hydroxide crystals, Then put it in a vacuum environment and decompose at 1000°C for 2 hours to obtain flaky alumina powder.

[0040] (2) Add flake aluminum oxide powder to the titanium-containing precursor solution, wherein the components in the titanium-containing precursor solution include: 6wt% triblock polymer F127, 12wt% butyl phthalate , 0.7wt% hydrochloric acid and solvent, containing the tetrahydrofuran solution of ethanol / glycerol with a volume ratio of 78:10 in the solvent. Under hydrothermal reaction for 2 hours, alumina powder coated with titanium dioxide coating was obtained.

[0041] (3) Put the alumina powder coated with titania into the tube, heat-treat at 520°C for 1.5h, and place it in a vacuum system of 0.08MPa to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com