Method for pretreating lignocellulose by adopting alkaline eutectic solvent

A deep eutectic solvent and lignocellulose technology, which is applied in the pulping of cellulose raw materials, methods based on microorganisms, and fiber raw material processing, can solve the problems of high recovery energy consumption, environmental hazards, and non-renewable, and achieve operability Strong performance, improved recovery, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

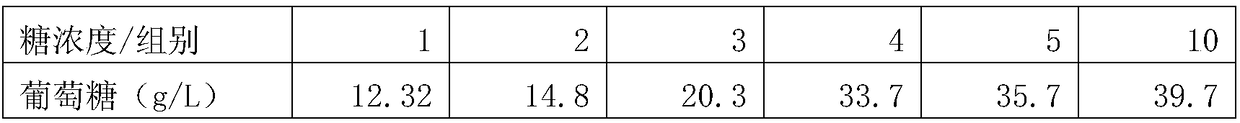

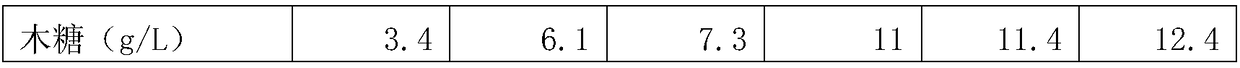

[0065] Sweet sorghum stalks were treated with choline / ethanolamine deep eutectic solvent, followed by enzymatic hydrolysis and saccharification.

[0066] (1) Absolutely dry sweet sorghum stalks with a particle size of less than 60 mesh are taken, and the stalks are washed with water to completely remove free sugar before drying.

[0067] (2) Preparation of deep eutectic solvent: prepare choline / ethanolamine deep eutectic solvent with a molar ratio of 1:1. The preparation method is to heat choline and ethanolamine mixed in a molar ratio of 1:1 to 90°C , maintained at 500rpm for 30min, and cooled to become the choline / ethanolamine deep eutectic solvent.

[0068] (3) The dry sweet sorghum slag was mixed with the pre-prepared deep eutectic solvent at a solid-liquid ratio of 1:20 (w / v) to obtain a solid-liquid mixture (slurry).

[0069] (4) Maintain the solid-liquid mixture (slurry) at 100° C. for 1 h.

[0070] (5) After the reaction is completed, cool to room temperature, and th...

Embodiment 2

[0073] Choline chloride / isopropanolamine / sodium hydroxide / water solution was used to pretreat corn stover residue with microwave assistance.

[0074] (1) Prepare corn stalk residue with a particle size below 60 mesh.

[0075] (2) Preparation of deep eutectic solvent: Prepare choline chloride / isopropanolamine deep eutectic solvent with a molar ratio of 1:2. After the two substances are fully mixed, the solid-liquid mixture is heated to 90°C, at 500rpm Keep it under low temperature for 30 minutes, when the solution in a homogeneous phase state is present, continue to add 10% volume of 20% (w / v) sodium hydroxide aqueous solution to the solution, continue stirring evenly, and cool to room temperature.

[0076] (3) Mix corn stalk residue with a particle size below 60 mesh with the above-mentioned deep eutectic solvent at a solid addition of 10% (w / v) to prepare a solid-liquid mixture.

[0077] (4) The solid-liquid mixture was placed in a closed reactor, and the reactor was heated ...

Embodiment 3

[0080] Chlorobetaine / ethanolamine deep eutectic solvent treatment of corn cob and evaluation of the residue cleaning times on the efficiency of enzymatic hydrolysis.

[0081] (1) Prepare dry corn cobs with a particle size below 80 mesh.

[0082] (2) Preparation of deep eutectic solvent: prepare chlorinated betaine / ethanolamine deep eutectic solvent with the mol ratio of 2:1, its preparation method is, will be heated to choline and ethanolamine mixed with the mol ratio of 2:1 Keep at 90°C for 30 minutes at 500rpm, and cool to become the betaine chloride / ethanolamine deep eutectic solvent.

[0083](3) The absolute dry corn cob with a particle size below 80 meshes is mixed with the above-mentioned deep eutectic solvent according to the solid addition amount of 5% (w / v) to obtain a solid-liquid mixture.

[0084] (4) Put the solid-liquid mixture into an airtight container and react at 140° C. and 500 rpm for 1 h.

[0085] (5) After the reaction is finished, the solid matter is ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com