Vascularization-promoting bone-tissue engineering stent and preparation method and application thereof

A technology of bone tissue engineering and vascularization, applied in the field of biomedical materials, to achieve good practical application prospects, good osteoconductivity, and solve the effect of rapid repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

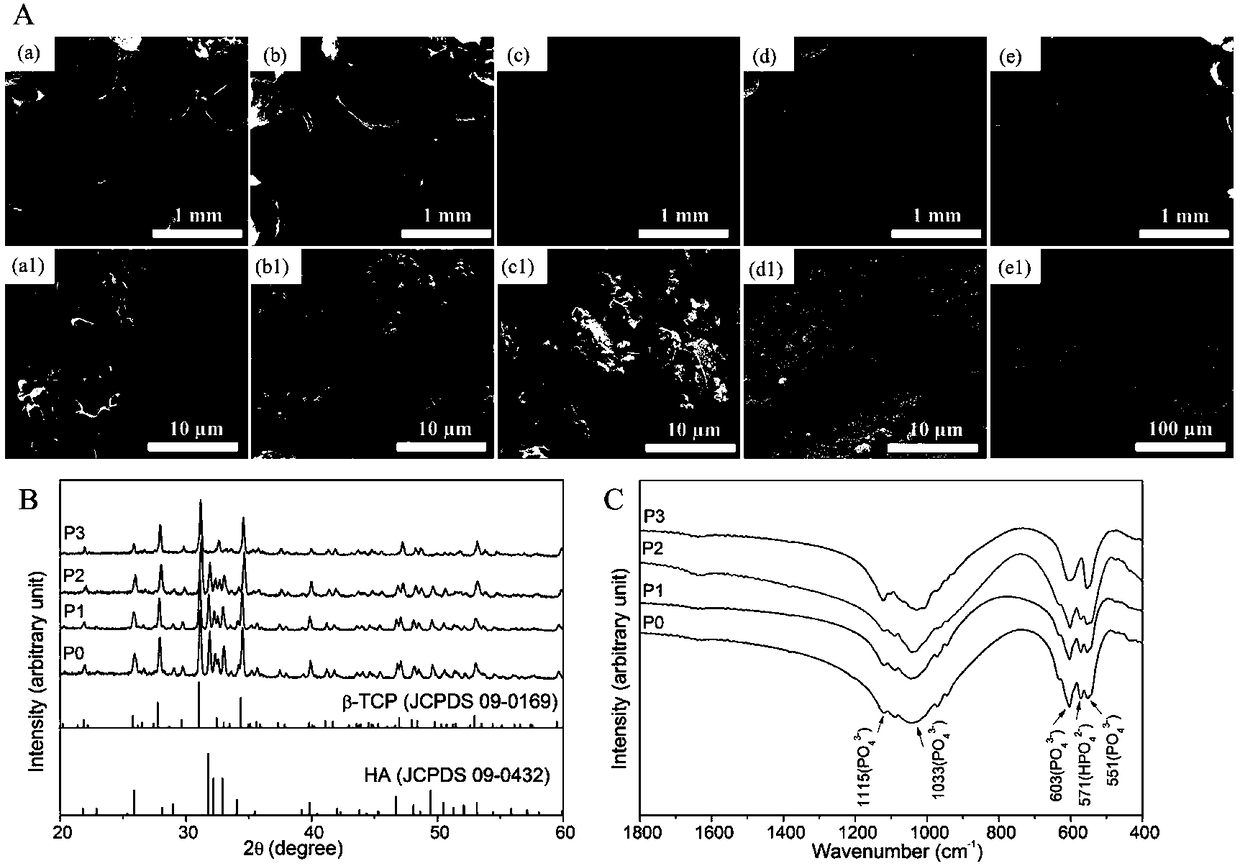

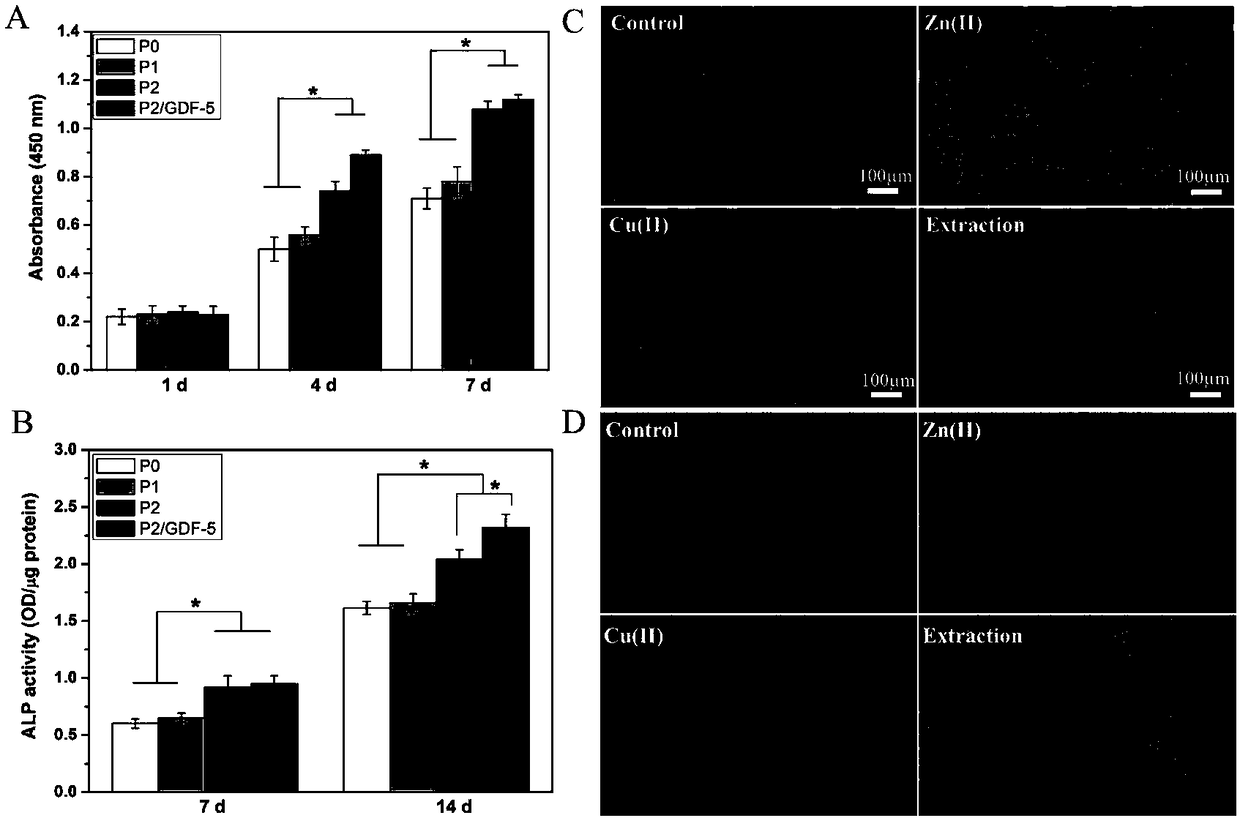

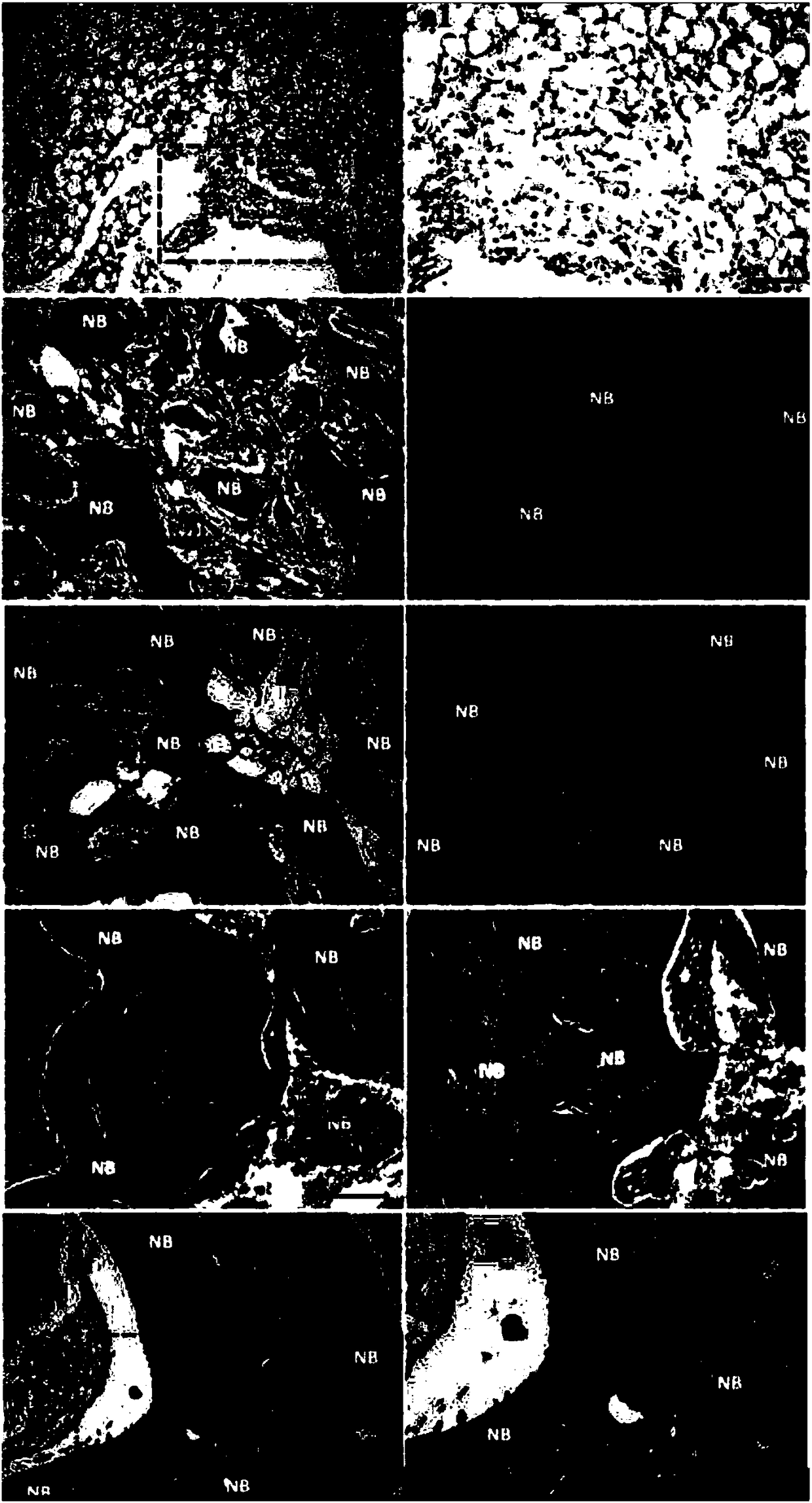

Method used

Image

Examples

Embodiment 1

[0043] (1) Using the chemical precipitation method, the aqueous solution containing calcium nitrate, copper nitrate, zinc nitrate and sodium lauryl sulfate is reacted with the aqueous solution of diamine hydrogen phosphate to prepare a calcium-deficient apatite slurry, which is dried to obtain Powder; Wherein, the mol ratio of described calcium nitrate, copper nitrate, zinc nitrate is 168:1:1;

[0044] (2) Mix the powder obtained in step (1) with the liquid phase solution to form a slurry; the liquid phase solution is a 2wt% sodium alginate solution, and the solid-to-liquid ratio is 20g: 100mL;

[0045] (3) Inject the slurry obtained in step (2) into a granular mold of closely packed calcium alginate balls, put it into a calcium chloride solution for molding, and sinter at 1200° C. for 2 hours after drying to obtain a porous calcium phosphate ceramic support;

[0046] (4) loading the PLGA microspheres loaded with GDF-5 on the surface of the obtained porous calcium phosphate ce...

Embodiment 2

[0054] Except that the molar ratio of calcium nitrate, copper nitrate and zinc nitrate is 40:1:1, the rest are consistent with Example 1.

Embodiment 3

[0056] Except that the molar ratio of calcium nitrate, copper nitrate and zinc nitrate is 15:1:1, the rest are consistent with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com