Supported copper sulfide photocatalyst used for sewage treatment and preparation method thereof

A photocatalyst and sewage treatment technology, which can be used in catalyst activation/preparation, physical/chemical process catalyst, light water/sewage treatment, etc. It can solve the problems of poor photocatalytic activity and stability, low specific surface area, and poor adsorption performance. , to achieve the effect of good photocatalytic activity and stability, large specific surface area, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

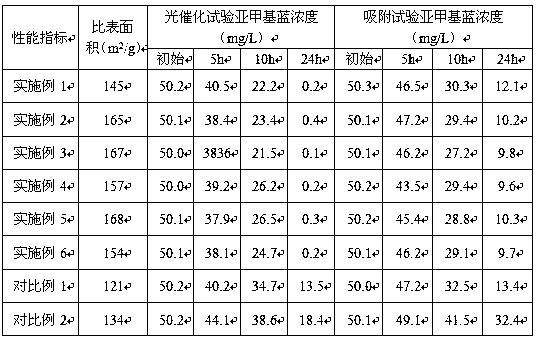

Examples

Embodiment 1

[0030] Calcinate halloysite nanotubes with an average diameter of 0.2 μm and an average length of 0.4 μm at 420° C. for 3.5 h to remove crystal water to obtain thermally activated halloysite nanotubes; add 26 kg of thermally activated halloysite nanotubes 74kg mass concentration is in the ethanol solution of chitosan of 35%, ultrasonic dispersion 17min, then filter, wash, dry, make chitosan modified halloysite nanotube; Get 26kg chitosan modified halloysite nanotube Add 57kg of cerium nitrate solution with a mass concentration of 37% into the tube, stir slowly for 8min, then add 8kg of sodium borohydride and 9kg of sodium hydroxide, continue stirring for 17min, then filter, wash, and dry to obtain cerium-loaded halloysite nano tube; the halloysite nanotubes of 13kg loaded with cerium were added into 14kg mass concentration of 22% sodium hydroxide solution, ultrasonically dispersed for 18min, then added 33kg mass concentration of 56% copper chloride solution and 40kg mass concen...

Embodiment 2

[0037] Calcinate halloysite nanotubes with an average diameter of 0.1 μm and an average length of 0.5 μm at 300° C. for 4 h to remove crystal water to obtain thermally activated halloysite nanotubes; add 20 kg of thermally activated halloysite nanotubes to 80 kg In the ethanol solution of chitosan with a mass concentration of 30%, ultrasonically disperse for 15min, then filter, wash, and dry to obtain chitosan-modified halloysite nanotubes; get 20kg chitosan-modified halloysite nanotubes Add 67 kg of cerium nitrate solution with a mass concentration of 35%, stir slowly for 5 min, then add 5 kg of sodium borohydride and 8 kg of sodium hydroxide, continue stirring for 15 min, then filter, wash, and dry to obtain halloysite nanotubes loaded with cerium It is 20% sodium hydroxide solution that the halloysite nanotube of 12kg load cerium that will make is added 10kg mass concentration, ultrasonic dispersion 15min, then adding 30kg mass concentration is that 50% cupric chloride solut...

Embodiment 3

[0040] Calcinate halloysite nanotubes with an average diameter of 0.3 μm and an average length of 0.3 μm at 500° C. for 2 h to remove crystal water to obtain thermally activated halloysite nanotubes; add 30 kg of thermally activated halloysite nanotubes to 70 kg In the ethanol solution of chitosan with a mass concentration of 38%, ultrasonically disperse for 20min, then filter, wash, and dry to obtain chitosan-modified halloysite nanotubes; get 30kg chitosan-modified halloysite nanotubes Add 48 kg of cerium nitrate solution with a mass concentration of 40%, stir slowly for 10 min, then add 10 kg of sodium borohydride and 12 kg of sodium hydroxide, continue stirring for 20 min, then filter, wash, and dry to obtain cerium-loaded halloysite nanotubes It is in the sodium hydroxide solution of 25% that the halloysite nanotube that the 15kg load cerium that makes is added 15kg mass concentration, ultrasonic dispersion 20min, then adding 35kg mass concentration is that 60% cupric chlo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com