Fischer-Tropsch synthesis catalyst and preparation method thereof

A Fischer-Tropsch synthesis and catalyst technology, which can be used in catalyst activation/preparation, carbon compound catalysts, catalysts, etc., and can solve the problems of difficult reduction of active components, weak interactions, and easy deactivation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

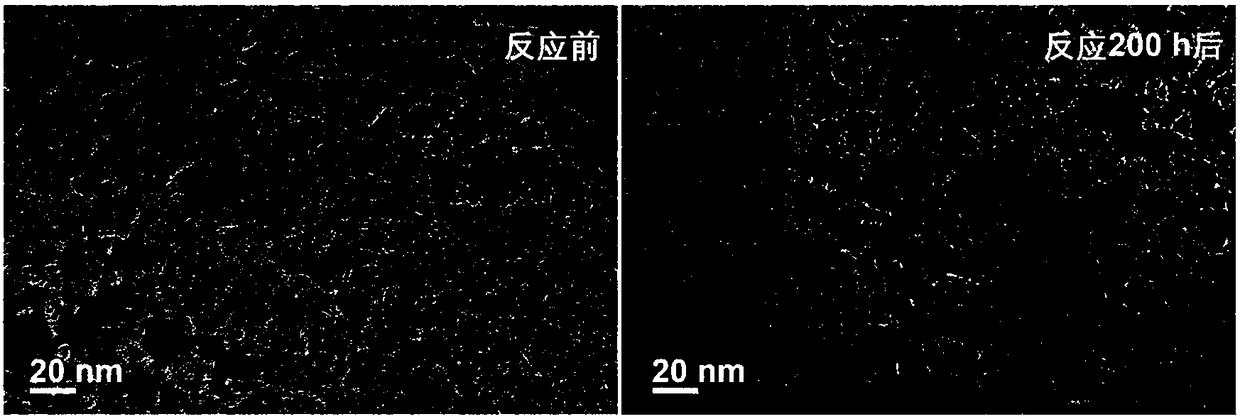

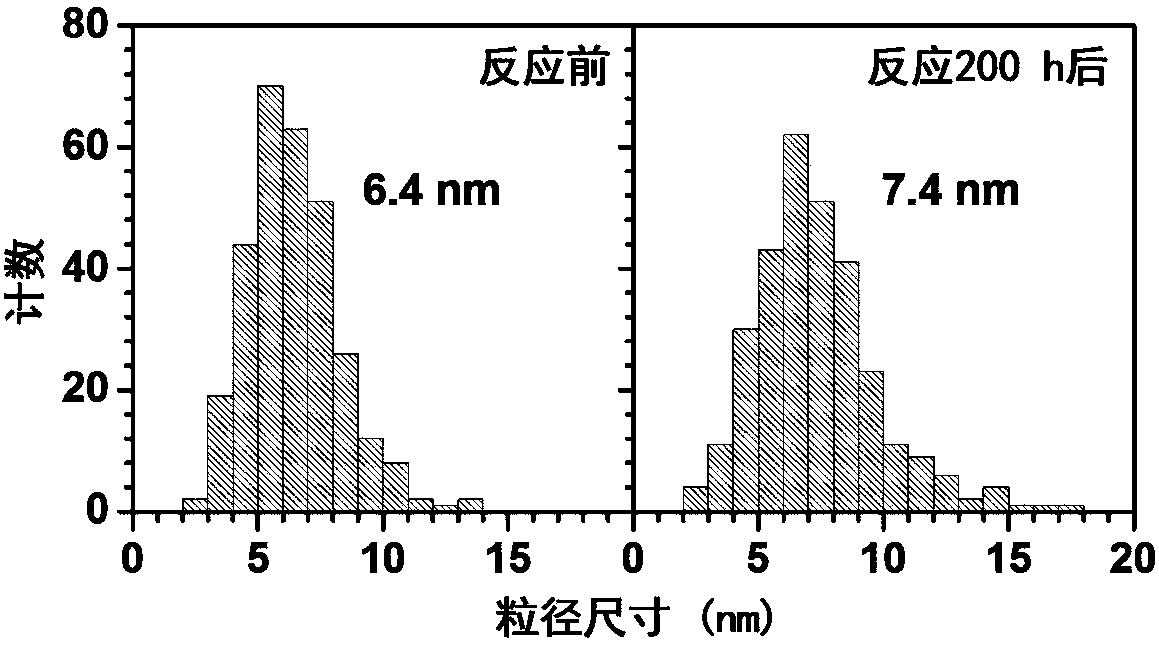

Image

Examples

preparation example Construction

[0032]The present invention also provides the preparation method of the Fischer-Tropsch synthesis catalyst described in the above technical scheme, comprising the steps of:

[0033] (1) Provide nitrogen-doped hollow carbon nanocages;

[0034] (2) impregnating the nitrogen-doped hollow carbon nanocage in an aqueous ethanol solution of a metal compound to obtain a Fischer-Tropsch synthesis catalyst precursor; the metal compound is a metal salt or a metal complex of iron or cobalt;

[0035] (3) The Fischer-Tropsch synthesis catalyst precursor is sequentially subjected to first calcination and passivation to obtain a Fischer-Tropsch synthesis catalyst.

[0036] (4) When the Fischer-Tropsch synthesis catalyst includes the first auxiliary agent or simultaneously includes the first auxiliary agent and the second auxiliary agent, the Fischer-Tropsch synthesis catalyst is heat-treated, and then mixed with an ethanol aqueous solution of a sodium salt or a potassium salt, Obtain the Fis...

Embodiment 1

[0069] (1) Provide nitrogen content of 12at.%, specific surface area of 1800m 2 / g, the pore volume is 4.2cm 3 / g, a particle size of 10-30nm nitrogen-doped hollow carbon nanocage (abbreviated as NCNC);

[0070](2) 1.45g ferric ammonium citrate and 15mL ethanol volume concentration are 20% ethanol deionized aqueous solution to mix, obtain the ethanolic aqueous solution of ferric ammonium citrate; 0.60gNCNC is mixed with the ethanolic aqueous solution of described ferric ammonium citrate, in Stir at 150r / min for 0.5h, then stand at room temperature and impregnate for 6h; dry the impregnated product in a drying oven at 80°C for 6h to obtain a Fischer-Tropsch synthesis catalyst precursor (Fe / NCNC precursor for short);

[0071] (3) Under the protection of Ar flow, the Fe / NCNC precursor was heated to 380 ° C for 2 h, and then naturally cooled to room temperature; then passed into an oxygen-containing inert gas with an oxygen volume content of 1% to passivate at room temperature ...

Embodiment 2

[0076] (1) Provide nitrogen content of 12at.%, specific surface area of 1800m 2 / g, the pore volume is 4.2cm 3 / g, a particle size of 10-30nm nitrogen-doped hollow carbon nanocage (abbreviated as NCNC);

[0077] (2) 0.784g ferric ammonium citrate is mixed with the ethanol deionized water solution of 20% ethanol volume concentration to obtain the ethanol water solution of ferric ammonium citrate; 0.60g NCNC is mixed with the ethanol water solution of described ferric ammonium citrate, in Stir at 150r / min for 0.5h, then stand at room temperature and impregnate for 6h; dry the impregnated product in a drying oven at 80°C for 8h to obtain a Fischer-Tropsch synthesis catalyst precursor (Fe / NCNC precursor for short);

[0078] (3) Under the protection of Ar flow, the Fe / NCNC precursor was heated to 380 ° C for 2 h, and then naturally cooled to room temperature; then passed into an oxygen-containing inert gas with an oxygen volume content of 1% to passivate at room temperature for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com