Preparation method of adhesive for paper tube

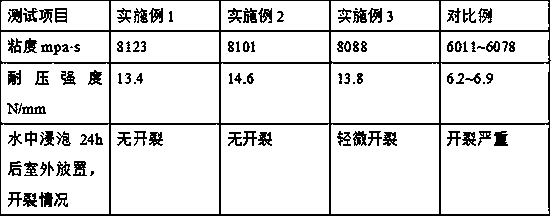

A paper tube glue, stirring and mixing technology, which is applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of paper tube pressure drop, poor water resistance, and low bonding strength of paper tube glue , to achieve the effects of enhancing toughness, improving water-resistant bonding performance, and improving compressive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] A preparation method for paper tube glue, comprising the steps of:

[0018] (1) Take sodium hydroxide and sodium silicate and add distilled water according to the mass ratio of 2:3:10, stir and mix for 20~30min, then add absolute ethanol with 2~3 times the mass of sodium hydroxide, heat up to 40~50℃ and stir Mix for 1-2 hours to obtain a mixture, take the mixture and add soybean meal powder at a mass ratio of 10:3, stir and mix at 50-60°C for 40-60 minutes to obtain a mixture, in parts by mass, take 20-30 parts of the mixture, 15 Mix ~20 parts of ethylene glycol divinyl glyceryl ether and 40~50 parts of diethylenetriamine, stir and mix at 35~40°C for 2~3 hours to obtain a stirred mixture;

[0019] (2) Take L-tartaric acid and mix it with acetyl chloride at a mass ratio of 4:5, then add phosphoric acid with 2-5% of the mass of L-tartaric acid, heat up to 70-75°C, stir and mix for 1-2 hours, and rotate to evaporate to obtain a rotary evaporator , take the rotary evaporat...

Embodiment 1

[0024] Soybean meal powder: low-temperature soybean meal powder, purchased from Jinluo Group, crushed through a 150-mesh sieve, and collected sieved particles.

[0025] A preparation method for paper tube glue, comprising the steps of:

[0026] (1) Take sodium hydroxide and sodium silicate and add distilled water according to the mass ratio of 2:3:10, stir and mix for 20 minutes, then add absolute ethanol twice the mass of sodium hydroxide, heat up to 40°C and stir and mix for 1 hour to obtain a mixed solution , take the mixed liquid and add soybean meal powder at a mass ratio of 10:3, stir and mix at 50°C for 40 minutes to obtain a mixture, in parts by mass, take 20 parts of the mixture, 15 parts of ethylene glycol divinyl glyceryl ether, 40 parts of diethylene triethylene Amines were mixed, and stirred and mixed at 35°C for 2 hours to obtain a stirred mixture;

[0027] (2) Take L-tartaric acid and mix it with acetyl chloride at a mass ratio of 4:5, then add phosphoric acid ...

Embodiment 2

[0032] Soybean meal powder: low-temperature soybean meal powder, purchased from Jinluo Group, crushed through a 150-mesh sieve, and collected sieved particles.

[0033] A preparation method for paper tube glue, comprising the steps of:

[0034] (1) Take sodium hydroxide and sodium silicate and add distilled water according to the mass ratio of 2:3:10, stir and mix for 30 minutes, then add anhydrous ethanol which is 3 times the mass of sodium hydroxide, heat up to 50°C and stir and mix for 2 hours to obtain a mixed solution , take the mixed solution and add soybean meal powder at a mass ratio of 10:3, stir and mix at 60°C for 60 minutes to obtain a mixture, in parts by mass, take 30 parts of the mixture, 20 parts of ethylene glycol divinyl glyceryl ether, 50 parts of diethylene triethylene Amines were mixed, stirred and mixed at 40°C for 3 hours to obtain a stirred mixture;

[0035] (2) Take L-tartaric acid and mix it with acetyl chloride at a mass ratio of 4:5, then add phosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com