Preparation method of tin-silicon-based graphne ball negative electrode material for lithium ion battery

A lithium-ion battery, graphene ball technology, applied in battery electrodes, circuits, electrical components and other directions, can solve the problems of urgent improvement of material rate performance, poor cycle stability, coating and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a method for preparing a tin-silicon-based graphene ball negative electrode material for a lithium ion battery, comprising the following steps:

[0028] (1), silicon ester monomer is dissolved in organic solvent, is prepared into mixed solution A, takes the tin dioxide ball that diameter is 10-20nm for subsequent use;

[0029] (2), uniformly mix the mixed solution A with tin dioxide balls according to the metering ratio, and then dry at 30-70°C to obtain a tin dioxide composite material coated with silicon ester monomers;

[0030] (3), putting the tin dioxide composite material coated with silicon ester monomer in step (2) into a muffle furnace for calcining, to obtain tin dioxide nanospheres coated with silicon dioxide;

[0031] (4), put the silicon dioxide-coated nano-tin dioxide nanospheres into the tubular atmosphere furnace, fill the tubular atmosphere furnace with carrier gas and carbon source gas, and use chemical vapor deposition to prepar...

Embodiment 1

[0039] A preparation method of tin-silicon-based graphene ball negative electrode material for lithium ion battery, the steps are as follows:

[0040] (1), weigh 0.048g ethyl orthosilicate (Si(OC 2 h 5 ) 4 ) was dissolved in 5 g of N-methylpyrrolidone to obtain solution A, and 1.868 g of tin dioxide balls with a diameter of 20 nm were weighed and dried in vacuum at 60° C. for later use.

[0041] (2) Add 1.868g of vacuum-dried tin dioxide balls with a diameter of 20nm into solution A, ball mill and mix for 1 hour, and dry at 50°C in a blast drying oven to obtain ethyl orthosilicate / tin dioxide composite material.

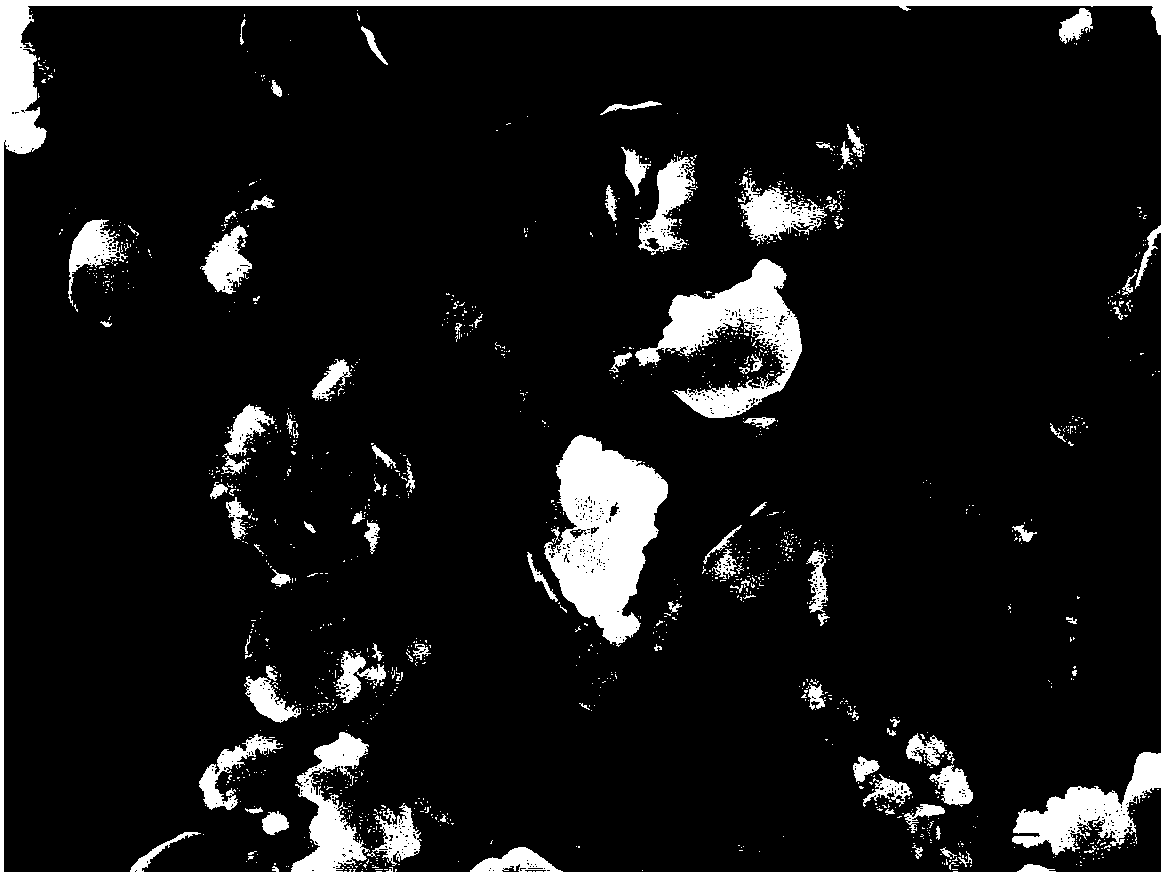

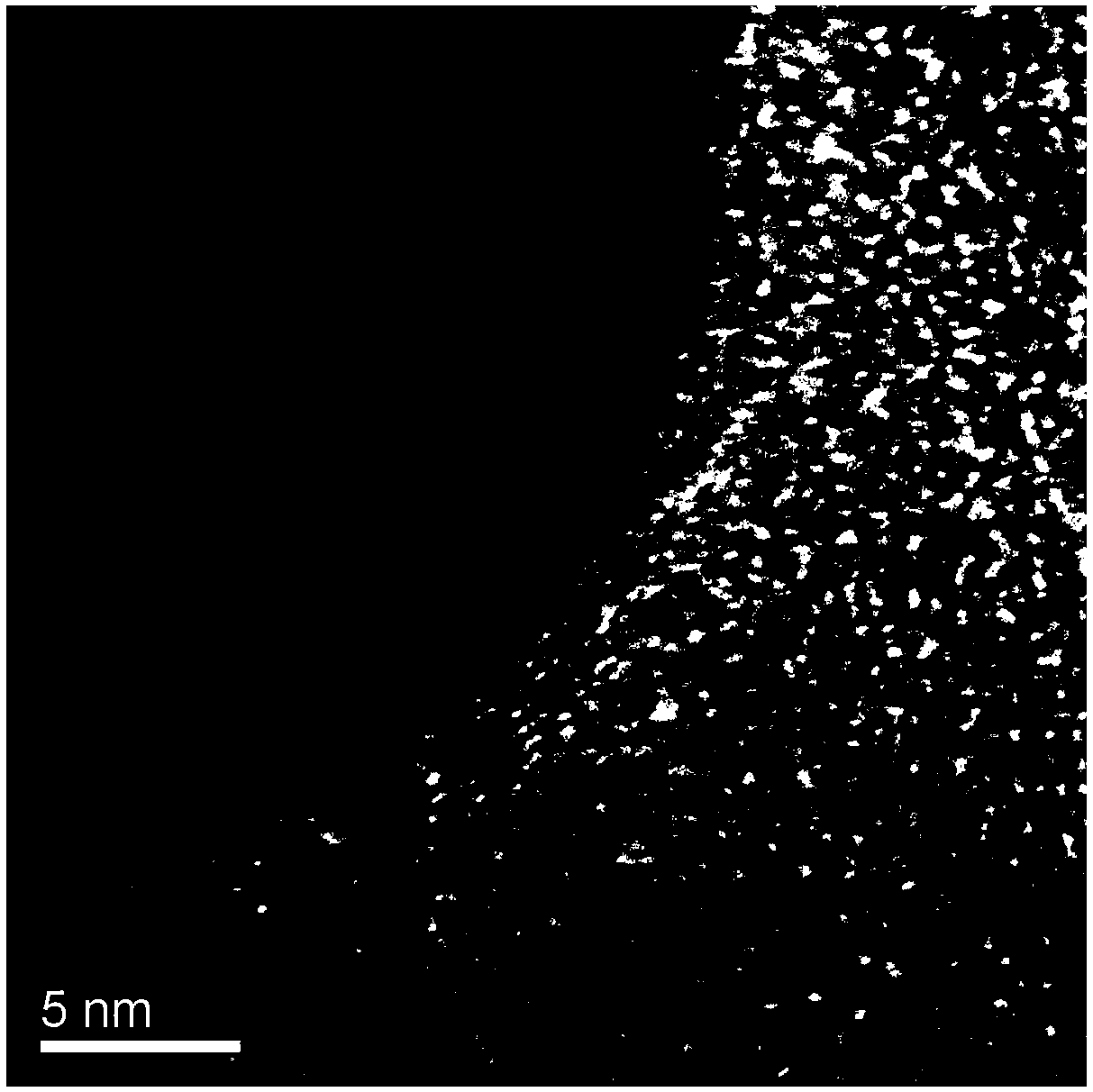

[0042] (3), then put the obtained material into a muffle furnace and bake at 200° C. for 30 minutes to obtain silicon dioxide-coated tin dioxide balls, such as figure 1 Scanning electron microscope images show that the resulting tin dioxide@silica spheres have a diameter of about 25 nm.

[0043] (4), the obtained 25nm silicon dioxide-coated tin dioxide balls are...

Embodiment 2

[0047] A preparation method of tin-silicon-based graphene ball negative electrode material for lithium ion battery, the steps are as follows:

[0048] (1) Weigh 0.032g of tetraethyl orthosilicate and dissolve it in 5g of absolute ethanol to obtain solution A, weigh 1.568g of tin dioxide balls with a diameter of 15nm and dry them in vacuum at 60°C for later use.

[0049] (2) Add 1.568g of tin dioxide balls with a diameter of 15nm after vacuum drying to solution A, and after ball milling and mixing for 0.1h, dry at 70°C in a blast drying oven to obtain ethyl orthosilicate / dioxide tin composite.

[0050] (3) Then put the obtained material into a muffle furnace and bake at 300° C. for 30 minutes to obtain silicon dioxide-coated tin dioxide balls with a diameter of about 19 nm.

[0051] (4) Put the obtained 19nm silica-coated tin dioxide ball into a tubular atmosphere furnace, use methane as the carbon source, and hydrogen / argon (hydrogen / argon = 1:1) as the carrier gas , chemica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com