Preparation and application of adsorbent for removing impurities in propane material flow

An adsorbent, propane technology, applied in the field of adsorbent preparation, can solve the problems of reduced reaction activity, decreased adsorption capacity, incomplete regeneration, etc., and achieves the effects of high adsorption capacity, large adsorption capacity and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] will be 540g ρ -Al 2 o 3 Powder, 359g13X molecular sieve and 0.9g of lanthanum oxide are mixed, and then placed in a flat-bottomed rotating disk for rotatable molding, spraying a certain amount of water during the rotatable molding process, screening the particles with a diameter of 1~3 mm, at 80 °C Bake for 6h, then bake at 140°C for 1h, and then bake at 500°C for 2h to prepare Sample 1.

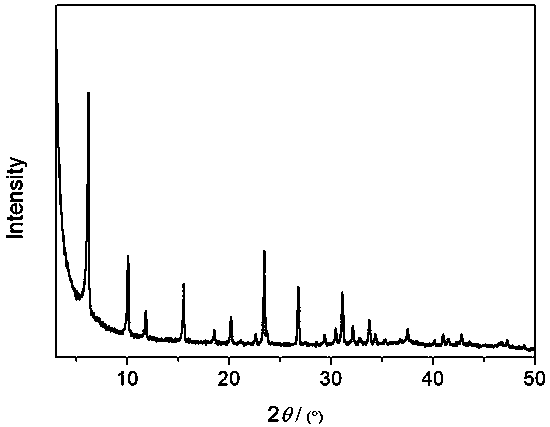

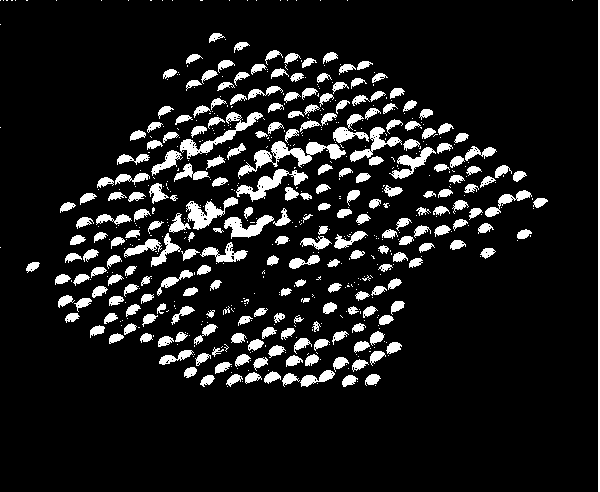

[0044] Grind sample 1 into powder for XRD analysis, such as figure 1 shown. Sample 1 is particles with a diameter of 1~3mm, such as figure 2 shown.

Embodiment 2

[0046] A fixed bed reactor was used to evaluate the adsorption performance of the adsorbent prepared in Example 1. The size of the reactor bed is 4 mm (ID) × 25 mm (H), the loading amount of the adsorbent is 10 g, and the two ends of the bed are filled with glass beads. Purge the adsorbent bed with nitrogen at 200°C for 4h, WHSV=500h -1 , then cooled to 35 °C. Use propane containing 200 ppm (mole) methanol, 200 ppm (mole) dimethyl ether and 200 ppm (mole) butadiene as the adsorbent evaluation medium, according to 2~3h -1 The space velocity of WHSV is continuously fed under the outlet pressure of 2.3MPa, and is detected online by gas chromatography with a helium ion detector (HID). Through the online detection of gas chromatography, the time when the adsorbent is saturated and penetrated under different outlet concentrations (PPM level) can be known, combined with the total flow rate and impurity component content, the saturation of the adsorbent under different impurity outl...

Embodiment 3

[0048] The rapid aging method is used to test the effective adsorption capacity of the adsorbent after frequent regeneration. After the adsorbent is saturated once as described in Example 2, it is purged with nitrogen for 30 min at 260 °C, and the bed is cooled to 35 °C. , switch the gas path to propane, let the impurity stream flow through the adsorbent bed according to the method described in Example 2 and record the adsorption saturation time. The above steps represent a cycle in the rapid aging test. The adsorbent that completed 80 cycles had an adsorption capacity of 25.8 g / 100 g adsorbent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com