Preparation method of ultra violet (UV) light curing-type polymethyl siloxane with methacrylate structure-contained side group

A technology of methacrylate and polymethylsiloxane, which is applied in the field of preparation of UV-curable methyl silicone oil materials, can solve problems such as expensive catalysts, low acrylate grafting efficiency, and easy crosslinking, and achieve Excellent low surface energy, excellent release effect, and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

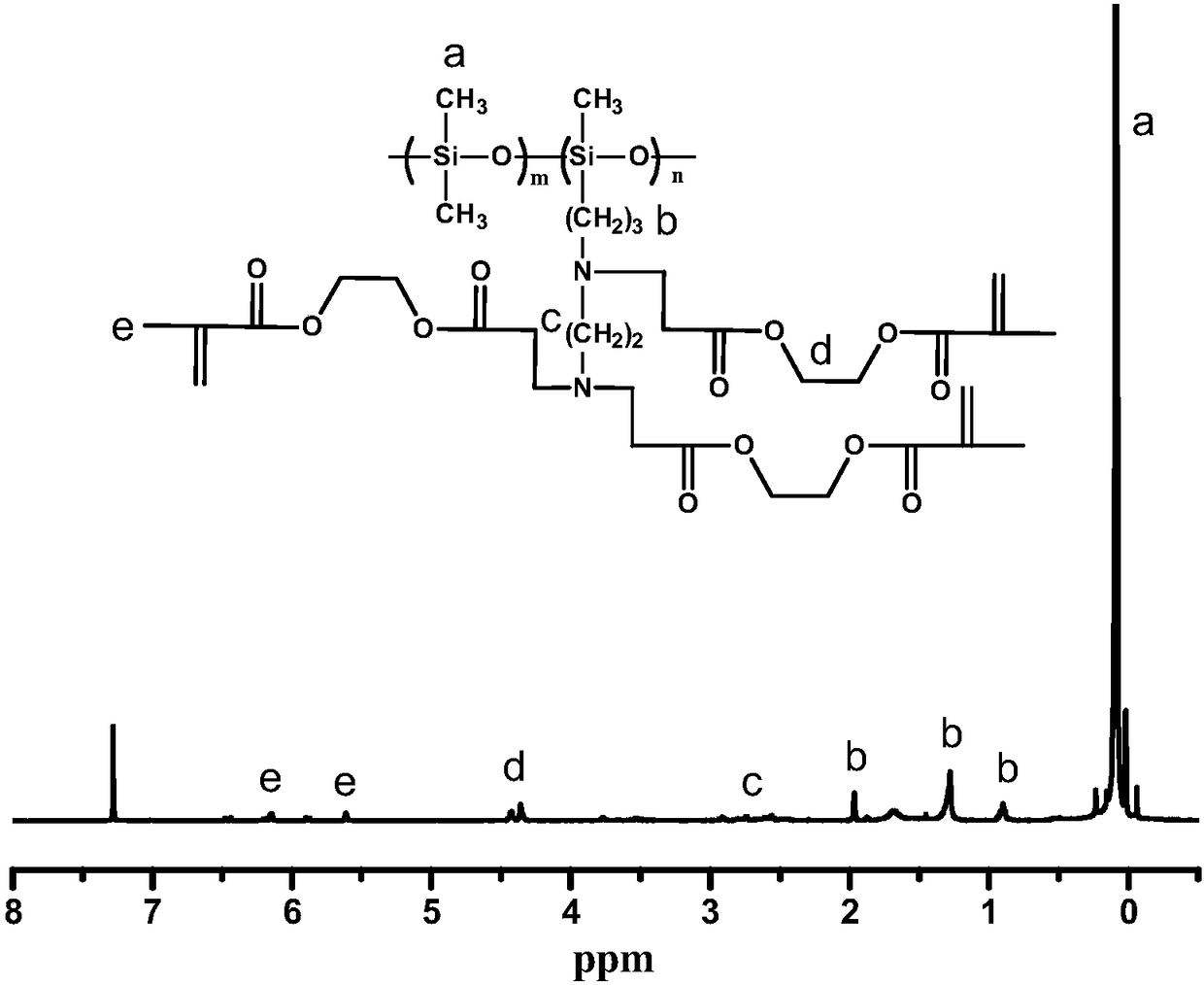

[0029] Synthesis of polymethylsiloxane material (PSi-MA) with side group containing methacrylate structure.

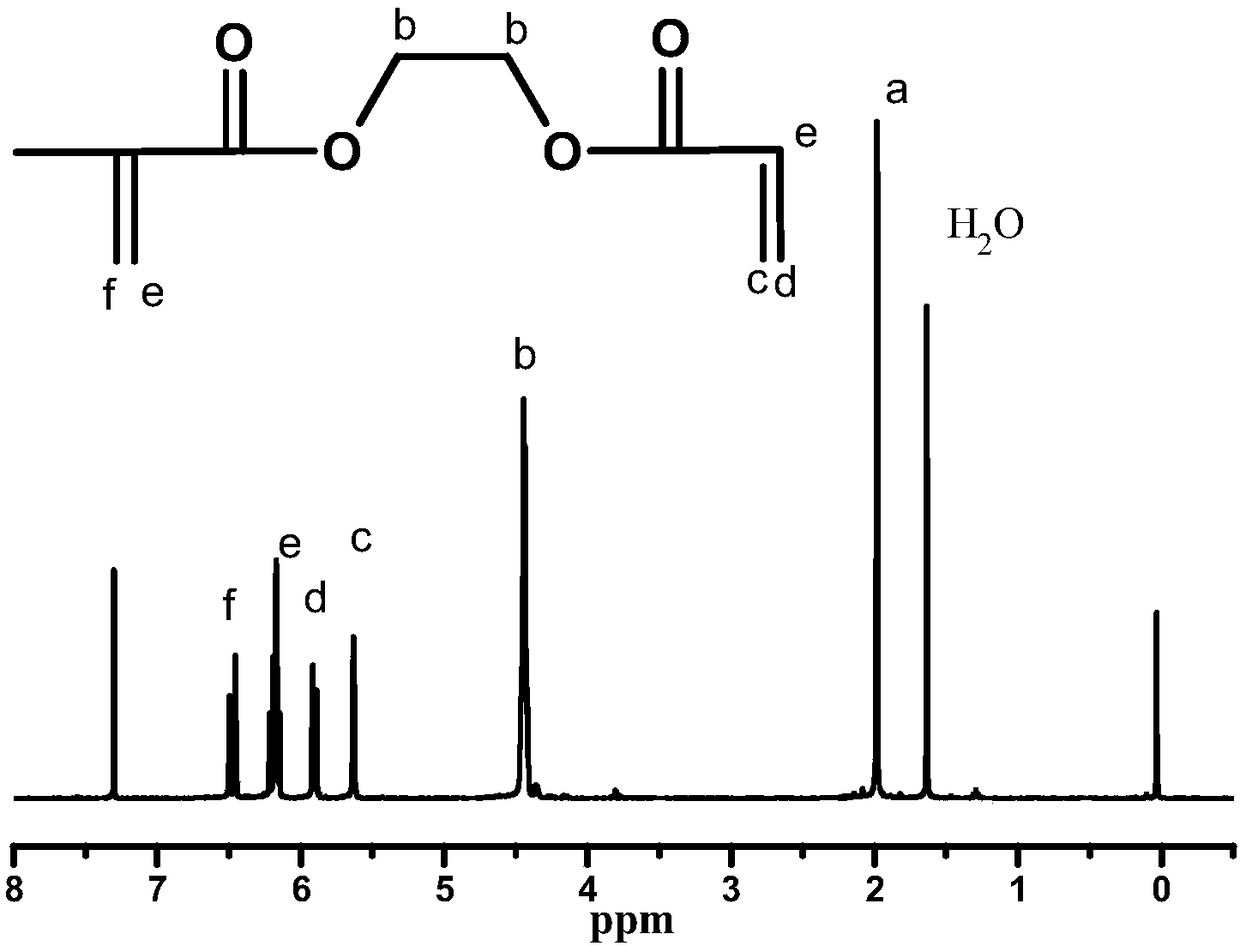

[0030] Ethylene glycol methacrylate, asymmetric diene structure, self-made, controllable for Michael addition reaction, figure 1 It is the NMR spectrum of ethylene glycol methacrylate. The protons of the structure correspond to the NMR signal peaks one by one, and the integral ratio is consistent with the proton ratio, indicating that it is the target reactant.

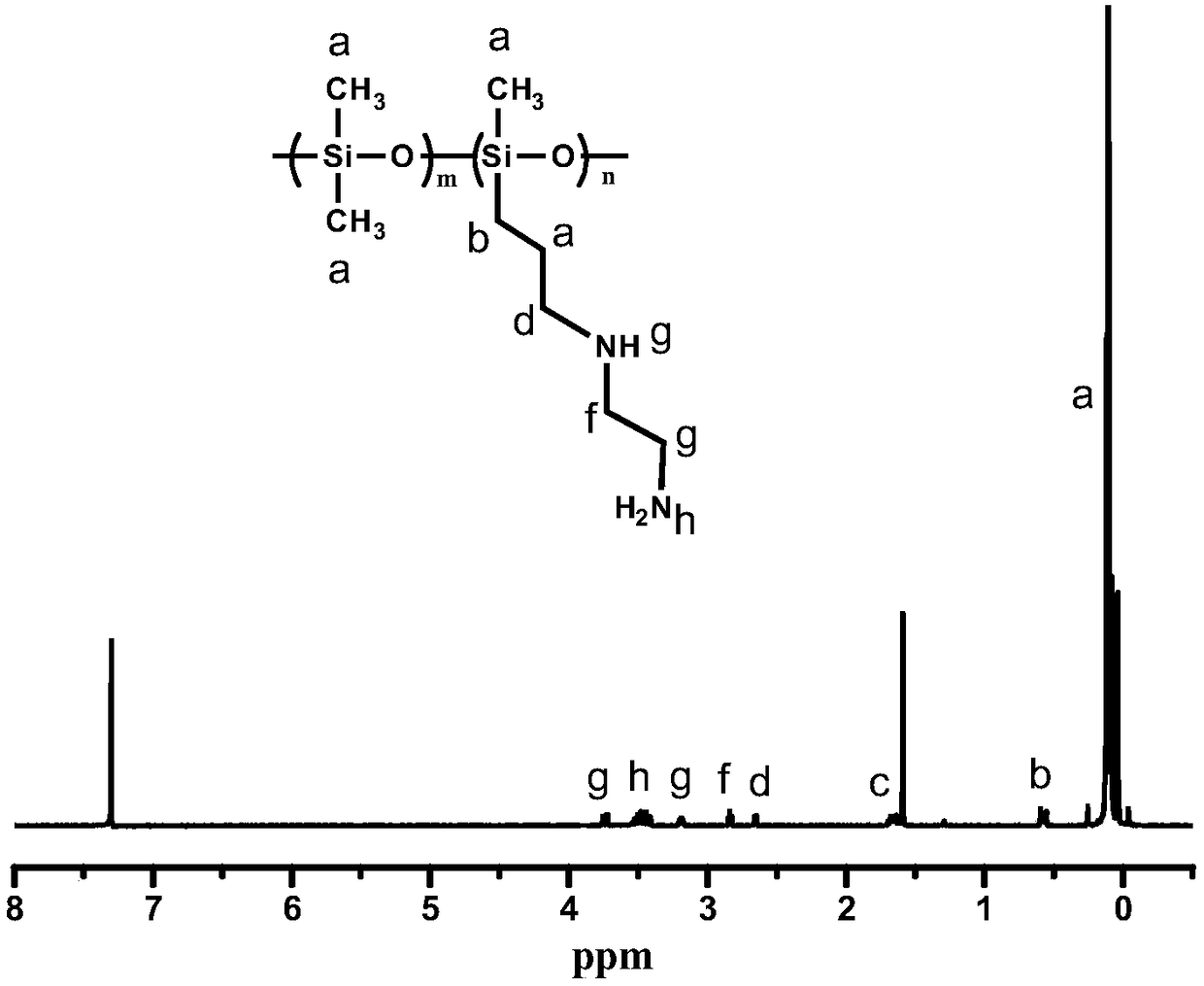

[0031] Amino silicone oil, i.e. aminopolymethoxysiloxane, has a structure such as formula [1], a molecular weight of 8200, self-made, figure 2 It is the nuclear magnetic spectrum of amino silicone oil, and the structure corresponds to the nuclear magnetic proton peak one by one. Through integral calculation, m=100, n=5, and the molar content of aminomethylsiloxane is 4.8%.

[0032] Amino silicone oil (10.00 g, 0.00125 mol) and solvent tetrahydrofuran (100 mL) were added to a 250 mL three-neck flask equipped ...

Embodiment 2

[0034] Synthesis of polymethylsiloxane material (PSi-MA) with side group containing methacrylate structure.

[0035] The difference from Example 1 is that the molecular weight of amino silicone oil is 8200, m=90, n=10, and the molar content of aminomethylsiloxane is 10%.

[0036] Under the condition of not changing other conditions of Example 1, the weight parts of amino silicone oil and ethylene glycol acrylate methacrylate in the preparation process are respectively: 10 parts and 7 parts, the solvent consumption is constant, can use ethyl acetate, toluene, Xylene, methyl ethyl ketone, etc. replaced tetrahydrofuran, and the operation process remained unchanged. The nuclear magnetic spectrum and infrared characterization confirmed that PSi-MA was successfully prepared, and the grafting rate of methacrylate reached 95%. Designation PSi-MA02.

Embodiment 3

[0038] Synthesis of polymethylsiloxane material (PSi-MA) with side group containing methacrylate structure.

[0039] The difference from Example 1 is that the molecular weight of amino silicone oil is 8200, m=104, n=3, and the molar content of aminomethylsiloxane is 2.8%.

[0040] Under the condition of not changing other conditions of Example 1, the weight parts of amino silicone oil and ethylene glycol acrylate methacrylate in the preparation process are respectively: 10 parts and 2.5 parts, and the solvent consumption is constant, available ethyl acetate, toluene, Xylene, methyl ethyl ketone, etc. replaced tetrahydrofuran, and the operation process remained unchanged. The nuclear magnetic spectrum and infrared characterization confirmed that PSi-MA was successfully prepared, and the grafting rate of methacrylate reached 95%. Designation PSi-MA03.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Release force | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

| Release force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com