Preparation method of thermosensitive film for NTC powder and graphene compound plane

A graphene composite, graphene film technology, applied in the direction of flat products, non-adjustable metal resistors, electrical components, etc., can solve the limitation of the resistance range and convenience of thermistor and infrared detection applications, the resistance value is too large, The problem of large resistance value, etc., can improve the photoelectric conversion efficiency, reduce the internal resistance, and achieve the effect of good electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: at first, make composite monolithic film, single-layer graphene powder is pressed into 0.1mm thickness film, brushes NTC semiconductor thermosensitive material 100 nanometers of Mn on it 3 co 2 NiO 18-x (x>0.01) powder film formation, the two are just pressed into a piece of monolithic composite film; According to coating 100 nanometer Mn 3 co 2 NiO 18-x (x>0.01) Different powder quality can prepare multiple different Mn 3 co 2 NiO 18-x monolithic composite film.

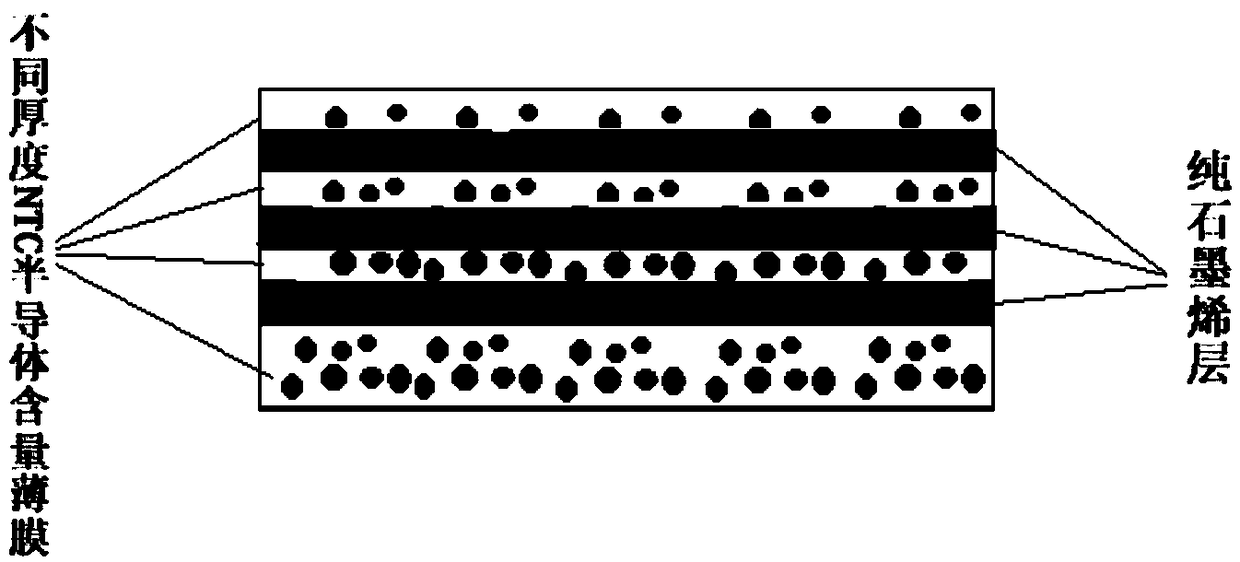

[0054] Secondly, make a laminated composite film, multiple different Mn 3 co 2 NiO 18-x content of monolithic composite films, according to Mn 3 co 2 NiO 18-x The content is high or low, stacked together in turn, and stacked together by pressure machinery or other tableting means to form a laminated composite film. The specific local microstructure of the laminated composite film is shown in the attached figure 1 shown.

Embodiment 2

[0055] Embodiment 2: at first, make composite monolithic thin film, NTC semiconductor thermosensitive material adopts average particle diameter 100 nanometers Mn 3 co 2 NiO 18-x (x>0.01) powder, single-layer graphene powder and heat-sensitive NTC semiconductor powder material according to the mass ratio 1:1, 1:3, 1:4, 1:5, 1:7: 1:9, Put the six kinds of mixed powder into the grinding equipment to grind and mix separately, and use the electron microscope to detect that after more than 90% of the NTC semiconductor powder is coated with graphene, it can be considered to be evenly mixed, and then the six different Mn 3 co 2 NiO 18-x content of mixed powders were compressed into tablets to make six kinds of single-chip composite films.

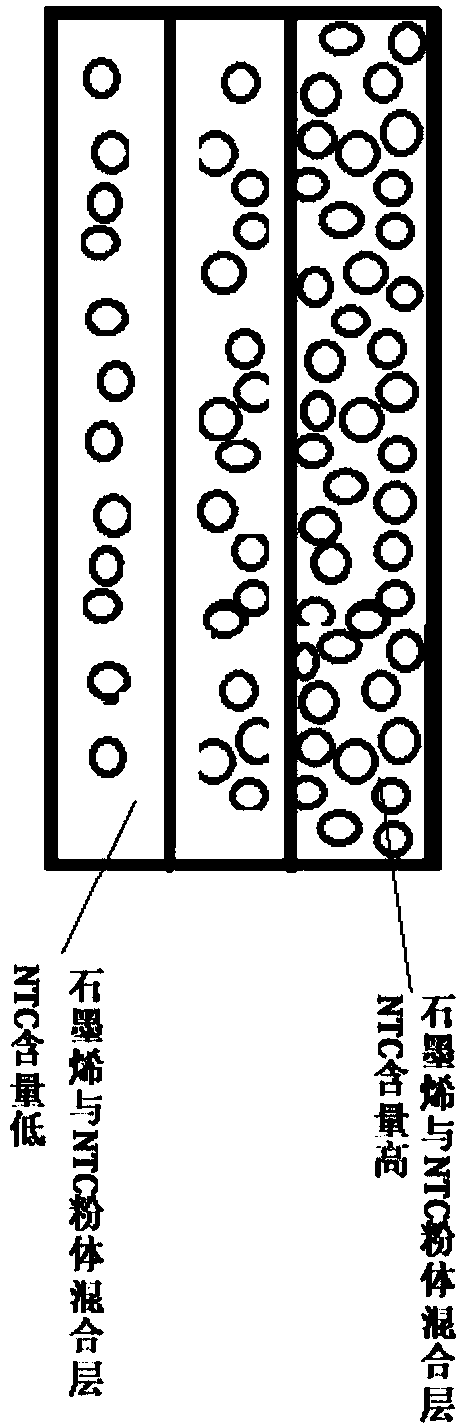

[0056] Secondly, make laminated composite films, six different Mn 3 co 2 NiO 18-x content of monolithic composite film, according to the Mn in the film 3 co 2 NiO 18-x The content is high or low, stacked together in turn, and stacked toge...

Embodiment 3

[0057] Embodiment 3: First, make a composite monolithic film. Stir and mix the single-layer graphene powder with water to form a suspension. Place a glass sheet in a container such as a beaker, let the single-layer graphene powder in the suspension settle on the glass surface, and wait for the graphene in the suspension to completely After the film is precipitated, the water above is clarified, and the water is poured out, and the graphene film on the glass is dried to remove residual moisture; then the glass sheet with graphene attached is placed in the container, and the Mn with an average particle size of NTC semiconductor is 50nm 3 CoNiCuO 18-x The powder is stirred and mixed with water to make a suspension, and it is also added to a container such as a beaker, so that the Mn in the suspension 3 CoNiCuO 18-x The powder is deposited on the glass surface, and the Mn in the suspension is allowed to stand 3 CoNiCuO 18-xAfter the powder is all precipitated into a film, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com