High-strength concrete based on rubber fiber compounding and preparation method thereof

A rubber fiber and high-strength technology, applied in the field of concrete, can solve problems such as poor fiber bonding and imperfect performance, and achieve the effects of enhanced properties, improved strength, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

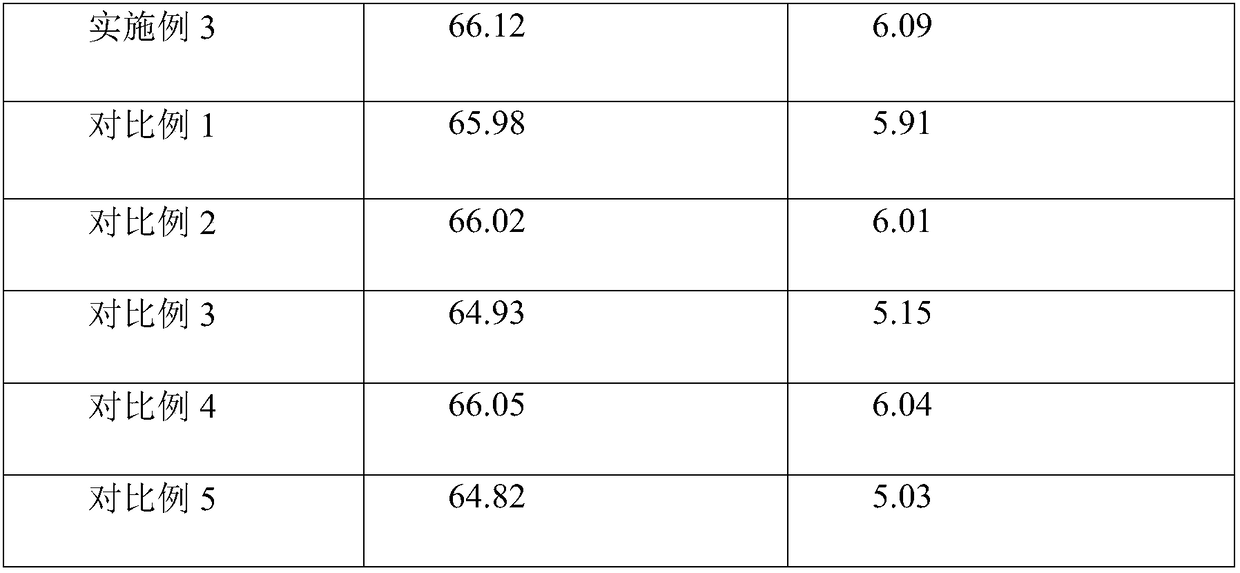

Examples

Embodiment 1

[0031] A kind of high-strength concrete based on rubber fiber composite of the present embodiment includes the following raw materials in parts by weight:

[0032] 42 parts of Portland cement, 18 parts of fine sand, 24 parts of pretreated composite fiber, 16 parts of modified silicone rubber, 8 parts of wollastonite, 5 parts of polycarboxylate superplasticizer, 4 parts of early strength agent, expansive green mud 3 parts of stone powder, 2 parts of faujasite, 1 part of gypsum powder, 18 parts of deionized water.

[0033] The preparation method of the pretreated composite fiber in this embodiment is to cut the polypropylene fiber and the aluminum silicate fiber to a particle size of 30 meshes, and then add them to the mixer, the stirring speed is 115r / min, and the stirring time is 6min. Then add epoxy silane coupling agent KH-560 to it, and then send it to the reflux device for reflux, the reflux temperature is 85°C, and the reflux time is 15min, then filter and dry to obtain t...

Embodiment 2

[0044] A kind of high-strength concrete based on rubber fiber composite of the present embodiment includes the following raw materials in parts by weight:

[0045] 46 parts of Portland cement, 22 parts of fine sand, 28 parts of pretreated composite fiber, 22 parts of modified silicone rubber, 14 parts of wollastonite, 9 parts of polycarboxylate superplasticizer, 10 parts of early strength agent, expansive green mud 5 parts of stone powder, 6 parts of faujasite, 3 parts of gypsum powder, 24 parts of deionized water.

[0046] The preparation method of the pretreated composite fiber in this embodiment is to cut the polypropylene fiber and the aluminum silicate fiber to a particle size of 40 meshes, and then add them to the mixer, the stirring speed is 125r / min, and the stirring time is 10min. Then add epoxy silane coupling agent KH-560 to it, and then send it to the reflux device for reflux, the reflux temperature is 95°C, and the reflux time is 25min, then filter and dry to obta...

Embodiment 3

[0057] A kind of high-strength concrete based on rubber fiber composite of the present embodiment includes the following raw materials in parts by weight:

[0058] 44 parts of Portland cement, 20 parts of fine sand, 26 parts of pretreated composite fiber, 19 parts of modified silicone rubber, 11 parts of wollastonite, 7 parts of polycarboxylate superplasticizer, 7 parts of early strength agent, expansive green mud 4 parts of stone powder, 4 parts of faujasite, 2 parts of gypsum powder, 21 parts of deionized water.

[0059] The preparation method of the pretreated composite fiber in this embodiment is to cut the polypropylene fiber and the aluminum silicate fiber to a particle size of 35 meshes, and then add them to the mixer, the stirring speed is 120r / min, and the stirring time is 8min. Then add epoxy silane coupling agent KH-560 to it, and then send it to the reflux device for reflux, the reflux temperature is 90°C, and the reflux time is 20min, then filter and dry to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com