A metallocene-containing porous polymer material and its preparation method

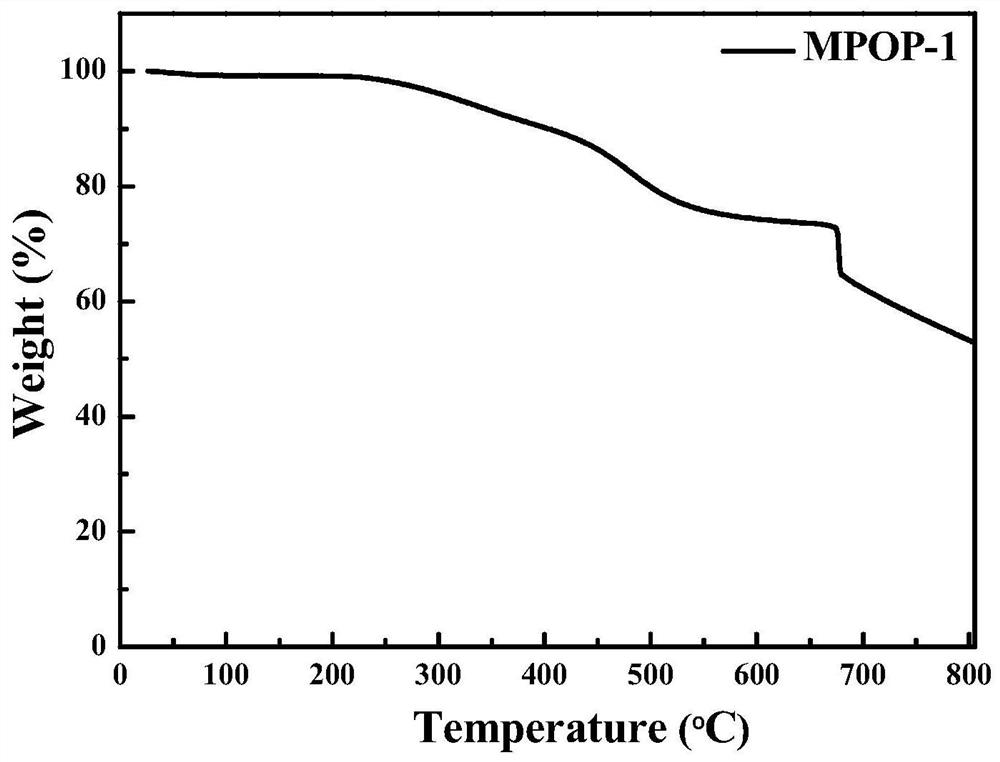

A technology of porous polymers and metallocene compounds, which is applied in the field of preparation of porous polymer materials, can solve the problems of limited application of new materials, weak interaction force, adsorption capacity, adsorption rate and selectivity cannot meet practical application, etc. The effect of good gas adsorption performance and structural stability, mild conditions, good chemical stability and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] This embodiment relates to a method for preparing a metallocene, comprising the following steps:

[0060] 1) At room temperature, add 0.372g of ferrocene, 1.954g of anhydrous aluminum trichloride, 1.066g of dimethoxymethane and 20mL of 1,2-dichloroethane into a two-necked round-bottomed flask equipped with a reflux condenser and a thermometer. alkyl. After the obtained mixture was uniformly stirred by magnetic force, the temperature was raised to 45° C. under the protection of nitrogen, and kept at this temperature for 5 hours. Then the temperature was raised to 80°C and stirring was continued for 19 hours.

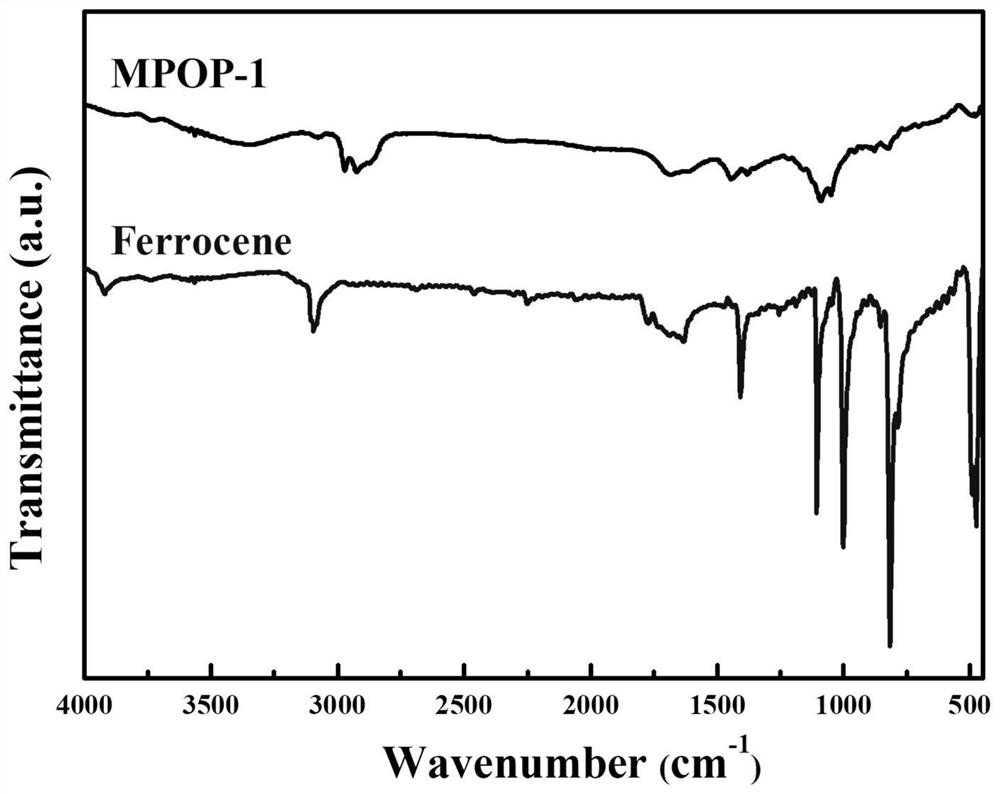

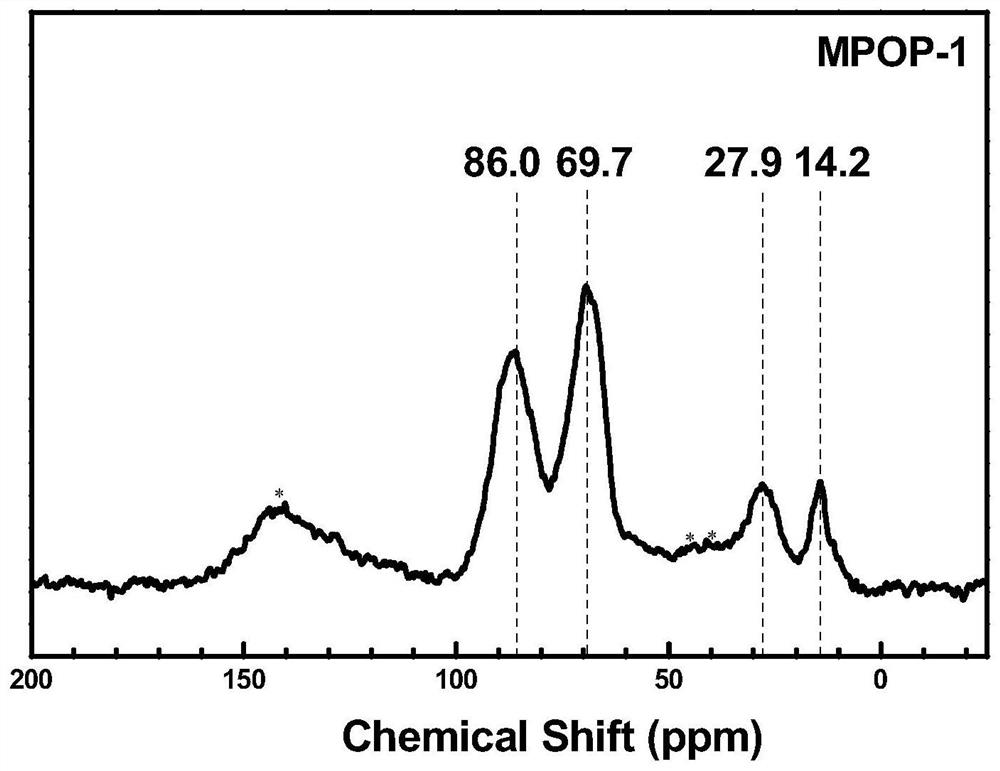

[0061] 2) After the reaction is terminated and cooled to normal temperature, add 50 mL of ethanol and stir for 1 hour, collect the crude product by filtration, wash with 10 wt% dilute hydrochloric acid and ethanol until the filtrate is colorless, and finally extract with ethanol in a Soxhlet extractor for 1 day . After drying under reduced pressure at 70°C, a br...

Embodiment 2

[0067] This embodiment relates to a method for preparing a metallocene, comprising the following steps:

[0068] 1) At room temperature, add 0.510g cyclopentadiene manganese tricarbonyl, 0.195g benzene, 1.217g anhydrous ferric chloride, 0.571g dimethoxymethane into a two-necked round bottom flask equipped with a reflux condenser and a thermometer and 20 mL of 1,2-dichloroethane. After the obtained mixture was uniformly stirred by magnetic force, the temperature was raised to 45° C. under the protection of nitrogen, and kept at this temperature for 5 hours. Then the temperature was raised to 80°C and stirring was continued for 19 hours.

[0069] 2) After the reaction was terminated and cooled to normal temperature, 50 mL of methanol was added and stirred for 1 hour. The crude product was collected by filtration, washed with methanol until the filtrate was colorless, and finally extracted with methanol in a Soxhlet extractor for 1 day. After drying under reduced pressure at 7...

Embodiment 3

[0075] This embodiment relates to a method for preparing a metallocene, comprising the following steps:

[0076] 1) At room temperature, add 0.255g cyclopentadiene manganese tricarbonyl, 0.195g benzene, 1.217g anhydrous ferric chloride, 0.571g dimethoxymethane into a two-necked round bottom flask equipped with a reflux condenser and a thermometer and 20 mL of 1,2-dichloroethane. After the obtained mixture was uniformly stirred by magnetic force, the temperature was raised to 45° C. under the protection of nitrogen, and kept at this temperature for 5 hours. Then the temperature was raised to 80°C and stirring was continued for 19 hours.

[0077] 2) After the reaction was terminated and cooled to normal temperature, 50 mL of methanol was added and stirred for 1 hour. The crude product was collected by filtration, washed with methanol until the filtrate was colorless, and finally extracted with methanol in a Soxhlet extractor for 1 day. After drying under reduced pressure at 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com