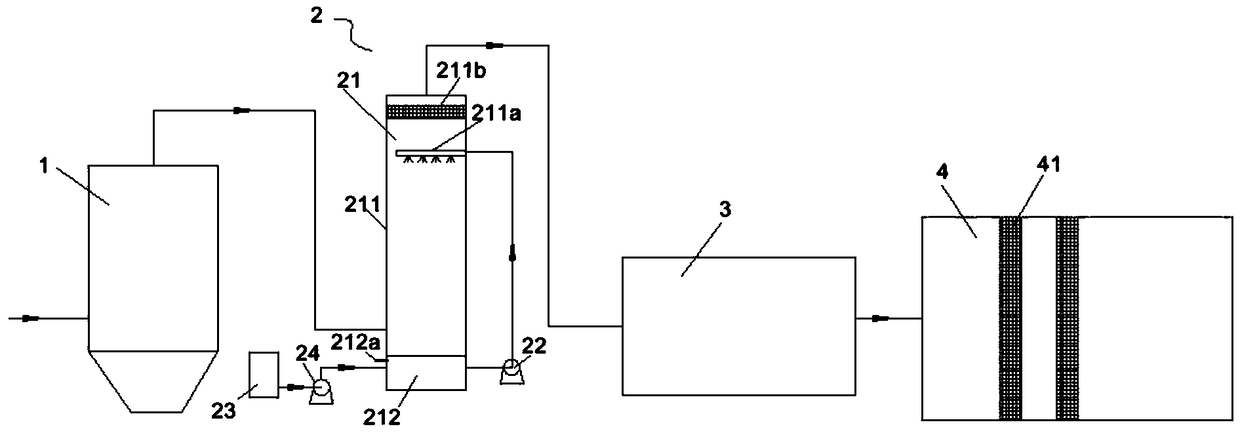

Exhaust gas treatment system

A waste gas treatment and tower body technology, applied in the direction of gas treatment, chemical/physical process, physical/chemical process catalyst, etc., can solve the problems of limited waste gas treatment capacity, waste gas treatment effect is difficult to meet the emission requirements, etc., to achieve low surface tension, Improve the treatment effect and prevent the effect of poisoning and inactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation of Cu-Mn-Ce composite catalyst:

[0043] (1) feed carbon dioxide into the first reactor, so that the pressure in the first reactor reaches the first preset pressure value 8MPa; then add copper nitrate, manganese nitrate, cerium nitrate in the first reactor And the mixed solution of absolute ethanol was heated up to 100°C while stirring.

[0044] Wherein, the molar ratio of copper nitrate, manganese nitrate and cerium nitrate is 0.2:0.5:1.

[0045](2) feed carbon dioxide into the second reactor so that the pressure in the second reactor reaches the second preset pressure value 7.9MPa; then add deionized water, citric acid in the second reactor The solution was mixed, and the temperature was raised to 100° C. while stirring.

[0046] (3) In step (2), the supercritical carbon dioxide that entrains the mixed solution of deionized water and citric acid is slowly passed into the first reactor, and the first reactor is stirred so that the deionized water Mix wel...

Embodiment 2

[0050] Preparation of Cu-Mn-Ce composite catalyst:

[0051] (1) In the first reactor, feed carbon dioxide, make the pressure in the first reactor reach the first preset pressure value 12MPa; Then add copper nitrate, manganese nitrate, cerium nitrate in the first reactor And the mixed solution of absolute ethanol was heated up to 130°C while stirring.

[0052] Wherein, the molar ratio of copper nitrate, manganese nitrate and cerium nitrate is 0.3:0.7:1.

[0053] (2) feed carbon dioxide into the second reactor so that the pressure in the second reactor reaches the second preset pressure value 11.7MPa; then add deionized water, citric acid in the second reactor The solution was mixed, and the temperature was raised to 130° C. while stirring.

[0054] (3) In step (2), the supercritical carbon dioxide that entrains the mixed solution of deionized water and citric acid is slowly passed into the first reactor, and the first reactor is stirred so that the deionized water fully mix ...

Embodiment 3

[0058] Preparation of Cu-Mn-Ce composite catalyst:

[0059] (1) feed carbon dioxide into the first reactor, so that the pressure in the first reactor reaches the first preset pressure value 15MPa; then add copper nitrate, manganese nitrate, cerium nitrate in the first reactor And the mixed solution of absolute ethanol is heated up to 160°C while stirring.

[0060] Wherein, the molar ratio of copper nitrate, manganese nitrate and cerium nitrate is 0.5:0.8:1.

[0061] (2) feed carbon dioxide into the second reactor so that the pressure in the second reactor reaches the second preset pressure value 14.5MPa; then add deionized water, citric acid in the second reactor The solution was mixed, and the temperature was raised to 160° C. while stirring.

[0062] (3) In step (2), the supercritical carbon dioxide of the mixed solution of deionized water and citric acid is slowly passed into the first reactor, and the first reactor is stirred so that the deionized water Mix well with ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com