Method for preparing sheet structured Cu nano-crystalline under room temperature condition

A nanocrystalline and conditional technology, applied in nanotechnology, metal processing equipment, transportation and packaging, etc., can solve problems such as difficult to remove, affect material application performance, increase complexity, etc., to ensure catalytic activity and facilitate industrial production , easy to remove effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

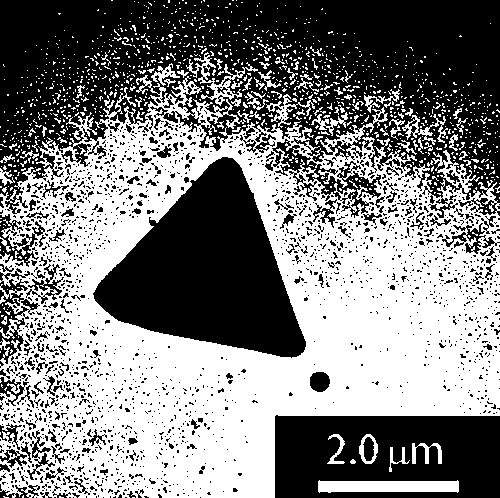

[0026] Embodiment 1: Preparation 1 of sheet-like structure Cu nanocrystals

[0027] With deionized water as solvent and copper sulfate as solute, configure a solution with a volume of 36 ml and a concentration of 38 mmol / L, and stir until uniform; add 3.6 g of anhydrous sodium carbonate, and after stirring uniformly, add 2.232 g of citric acid Sodium, stirred at room temperature for 5 minutes, then added 6.0 g of potassium bromide powder to the solution, stirred at room temperature for 5 minutes, injected a reducing agent ascorbic acid with a volume of 20 ml and a concentration of 1.5 mol / L, and stirred rapidly at room temperature for 30 minutes. The obtained product is separated by a centrifuge, dispersed in deionized water for ultrasonication, secondly centrifuged, dispersed in ethanol, and placed in a blast drying oven at 50 degrees after being centrifuged again for drying.

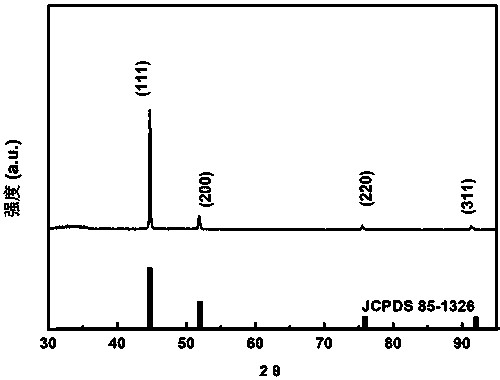

[0028] We first performed an X-ray diffraction test on the sample. From figure 1 It can be seen t...

Embodiment 2

[0030] Embodiment 2: The effect verification of potassium bromide.

[0031] In order to verify the effect of potassium bromide in the whole preparation, we implemented the following experiment: the operation in Example 1 "adding 6.0 grams of potassium bromide powder to the solution and stirring at room temperature for 5 minutes" was removed, and other conditions were unchanged. pass Figure 5 From the results of field emission scanning electron microscopy, it can be seen that Cu cannot form a sheet-like two-dimensional structure due to the participation of no additive potassium bromide. From this example, it can be concluded that bromide ions in potassium bromide can control the growth orientation of Cu nanocrystal seeds through directional adsorption.

Embodiment 3

[0032] Embodiment 3: Preparation 2 of sheet-like structure Cu nanocrystals

[0033] Change Example 1, preparation operation "20 milliliters, reducing agent ascorbic acid with a concentration of 0.68 mol / liter, stir rapidly at room temperature for 30 minutes" to "20 milliliters, reducing agent ascorbic acid with a concentration of 0.68 moles / liter, rapidly stir at room temperature for 90 minutes ". The obtained samples were scanned by scanning electron microscope as Figure 6 shown. The results show that the method of this example can also obtain sheet-like Cu nanocrystals. From this example, it can be concluded that prolonging the reaction time will not affect the structure of the product obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com