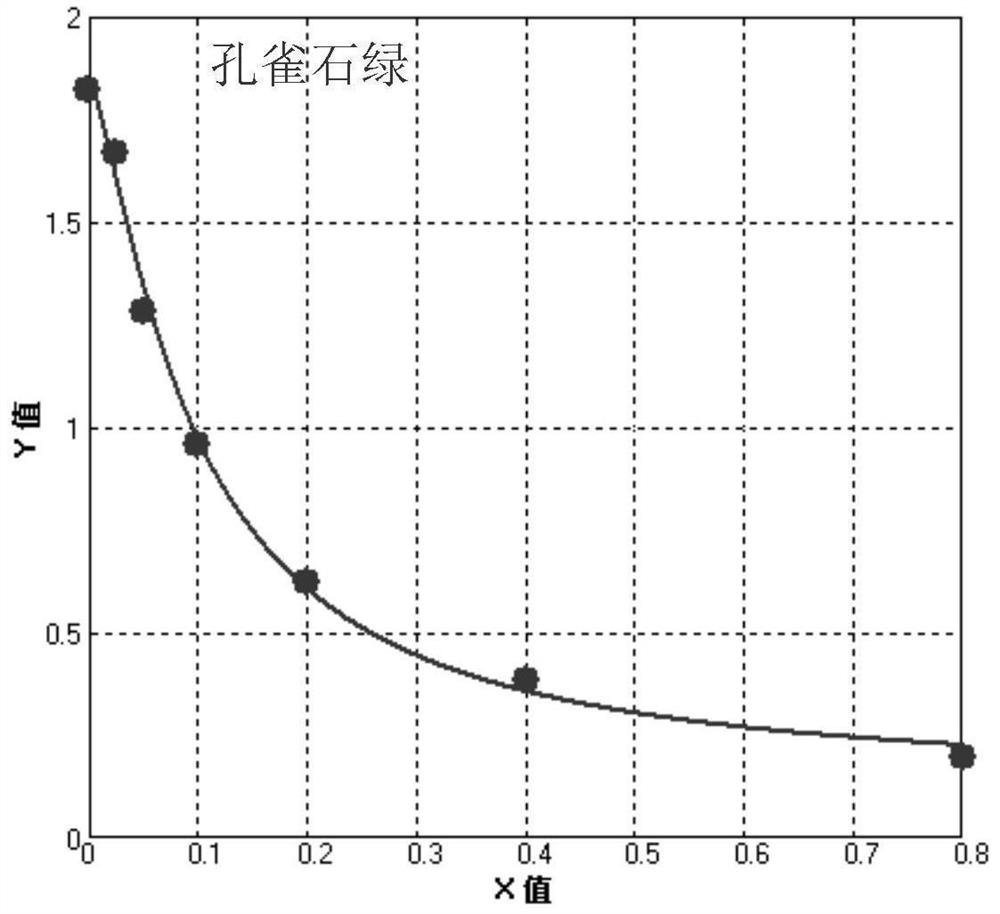

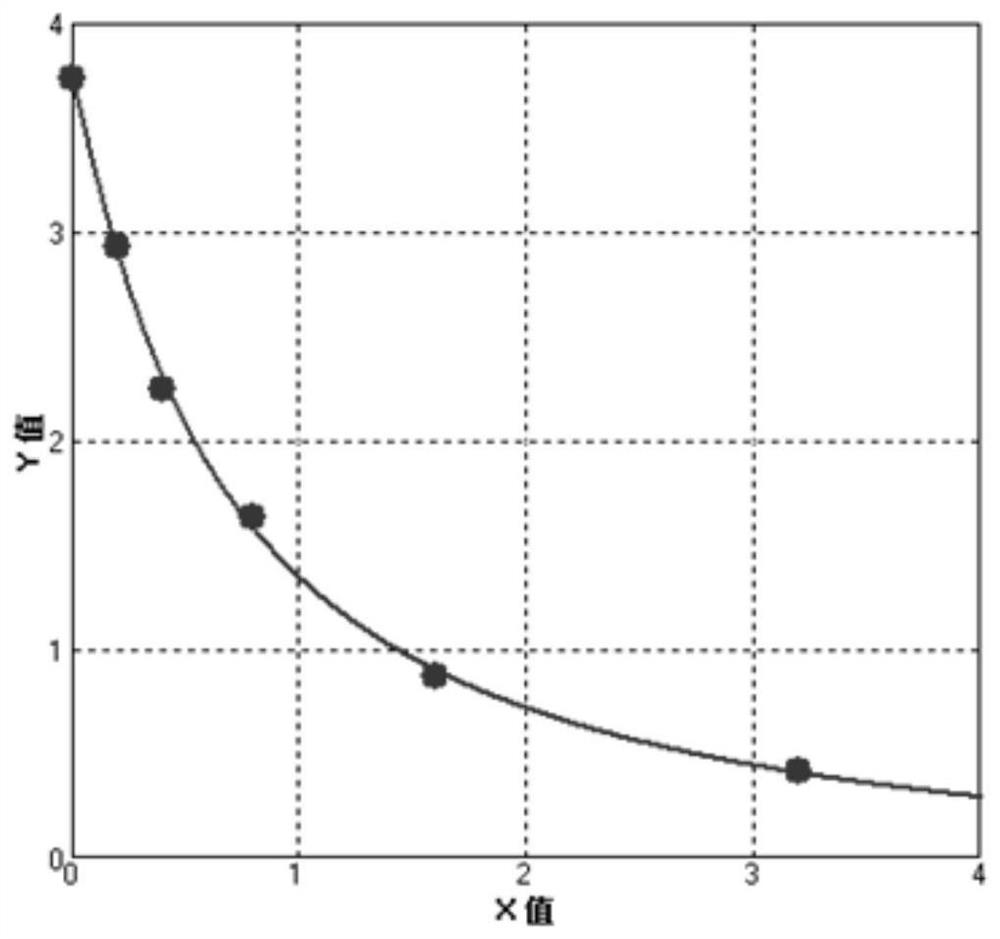

A malachite green hapten, artificial antigen and its application in fluorescence quantitative immunochromatography

A technology of malachite green and artificial antigen, which is applied in the field of immunochemistry, can solve the problems of expensive equipment operation, cumbersome, poor sensitivity, etc., and achieve the effect of improving immunogenicity, increasing recognition sites, and increasing potency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]A peacockstone green semi-antigen, the preparation method thereof is as follows:

[0045](1) Take 2.0 g (7.7 mmol) Compound II in a 50 ml round bottom flask, 20 mL of acetone, 2.6 g (19.3 mmol) compound I and 2.1 g (15.4 mmol) potassium carbonate were added, and at 65 ° C for 5 h, reaction After completing, 40 ml of purified water was decompressed, extracted twice with ethyl acetate, and then decompress the solvent, the column chromatography was purified 2.2 g of compound III (ethyl acetate / petroleum ether, 1 / 7, v / v );

[0046](2) 1.2 g (3.3 mmol) compound III is dissolved in 15 ml of anhydrous ethanol, add N, N-dimethylideil 2.0 g (16.5 mmol) and zinc chloride 2.2g (16.5 mmol), 80 ° C back to 26h After the reaction is completed, 40 ml of purified water is reduced, extracted with ethyl acetate, then decompress the solvent, and purify 0.8 g of compound IV (ethyl acetate / petroleum ether, 1 / 4, v / v) );

[0047](3) 0.8 g (1.0 mmol) of compound IV was dissolved in 5 ml of ethanol, an...

Embodiment 2

[0049]A peacockstone green semi-antigen, the preparation method thereof is as follows:

[0050](1) Take 2.0 g (7.7 mmol) of Compound II in 50 ml round bottom flask, 20 mL of acetone, 2.1 g (15.4 mmol) of Compound I and 1.7 g (11.6 mmol) potassium carbonate, reacting at 60 ° C for 2 h, reaction After completing, 40 ml of purified water was added, and 40 ml of purified water was added, ethyl acetate was extracted twice, and then the solvent was removed, and the column chromatography was purified. );

[0051](2) 1.2 g (3.3 mmol) compound III was dissolved in 13 ml of anhydrous ethanol, add N, N-dimethylideil 2.4 g (19.8 mmol) and zinc chloride 2.6 g (19.8 mmol), 85 ° C reflux 15h After the reaction is completed, 40 ml of purified water is reduced, extracted with ethyl acetate, then decompress the solvent, and purify 1.1 g of compound IV (ethyl acetate / petroleum ether, 1 / 4, v / v) );

[0052](3) 1.1 g (1.4 mmol) of compound IV was dissolved in 10 ml of ethanol, and 6 m of lithium hydroxide sol...

Embodiment 3

[0054]A peacockstone green semi-antigen, the preparation method thereof is as follows:

[0055](1) Take 2.0 g (7.7 mmol) Compound II in a 50 ml round bottom flask, 20 ml of acetone, 2.6 g (19.3 mmol) compound I and 2.1 g (15.4 mmol) potassium carbonate were added, and at 65 ° C for 3 h, reaction After completing, 40 ml of purified water was reduced pressure, extracted twice with ethyl acetate, and then decompress the solvent, column chromatography purified 2.1 g of compound III (ethyl acetate / petroleum ether, 1 / 7, v / v );

[0056](2) 1.2 g of Compound III was dissolved in 13 ml of anhydrous ethanol, added to N, N-dimethylideine 2.0 g (16.5 mmol) and zinc chloride 2.2 g (16.5 mmol), 83 ° C for 20 h, and the reaction is completed, Decompression removal, 40 ml of purified water was added, extracted with ethyl acetate, then decompress the solvent, and purified 0.9 g of compound IV (ethyl acetate / petroleum ether, 1 / 4, v / v);

[0057](3) 0.9 g of the compound IV was dissolved in 10 ml of eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| intra-assay coefficient of variation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com