Aramid fiber clutch surface patch and preparation technique thereof

A clutch face and aramid fiber technology, applied in the field of automobile transmission system, can solve the problems of friction performance change, water resistance decline, affecting driving safety, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

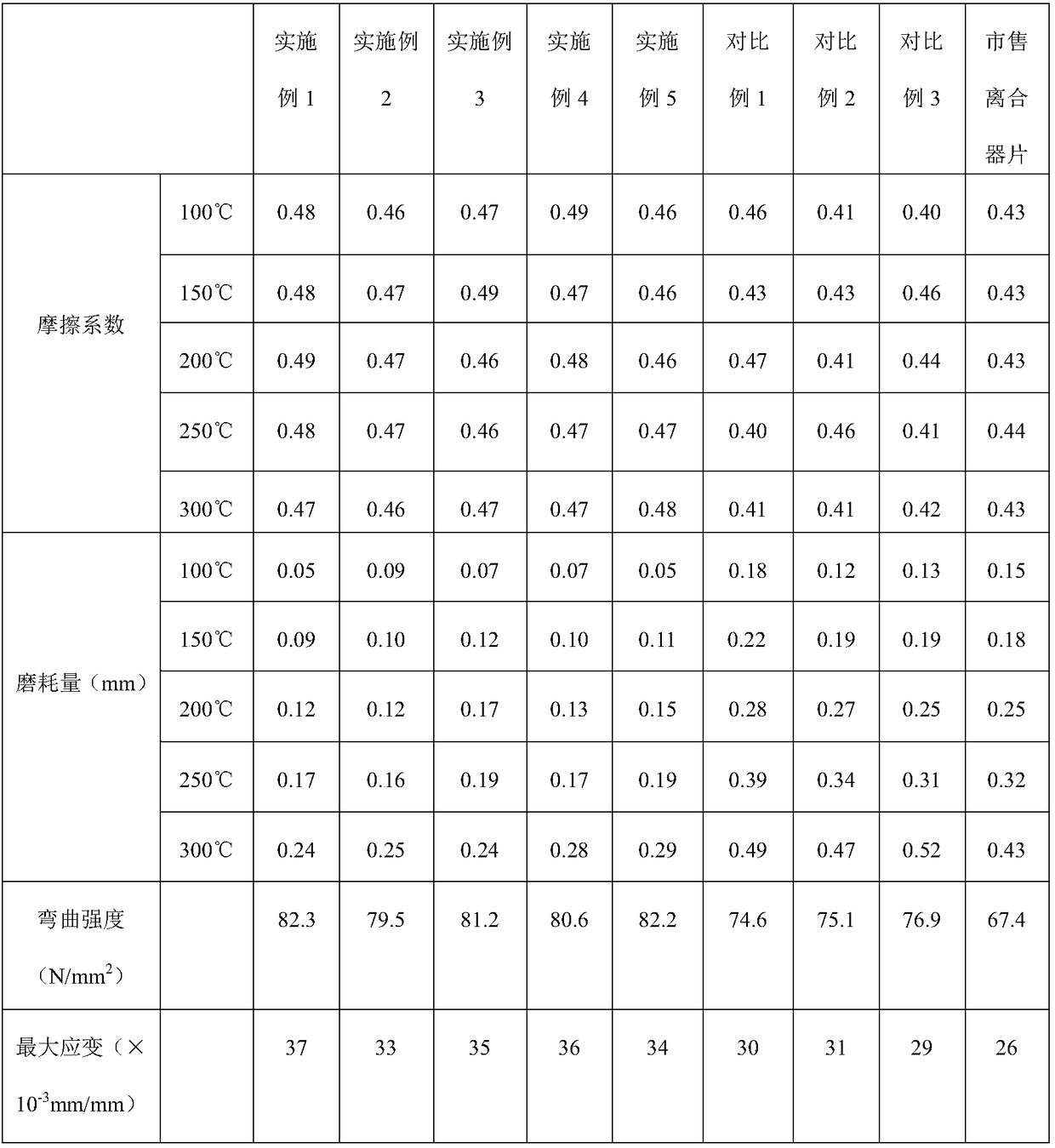

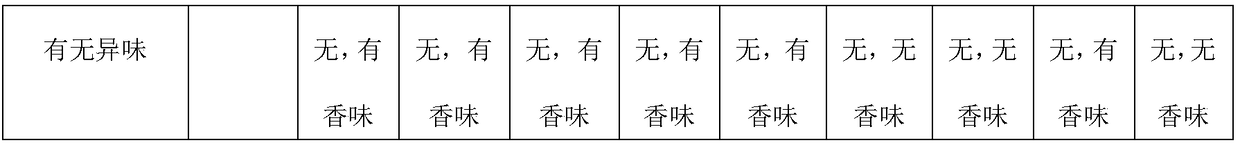

Examples

Embodiment 1

[0032] An aramid fiber clutch face, made of the following raw materials in parts by weight: 3 parts of nitrile rubber, 8 parts of glass fiber, 8 parts of aramid fiber, 8 parts of kapok fiber, 2 parts of plant powder, 3 parts of graphite, carbon 3 parts of black, 4 parts of nano-silica, 5 parts of aluminum hydroxide, 3 parts of zinc stearate, 13 parts of phenolic resin, and 1 part of sulfur.

[0033] The weight ratio of glass fiber, aramid fiber and kapok fiber is 1:1:1.

[0034] The plant powder is made from the following raw materials in parts by weight: 2 parts of peony bark.

[0035] The preparation process of plant powder is as follows:

[0036] (1): Pulverize 2 parts of Moutan Cortex and pass through a 60-80 mesh sieve for later use;

[0037] (2): Add 8 parts by weight of ethanol into the cortex moutan powder obtained in step (1), stir for 5 minutes and put it into a drying machine to dry to obtain a plant powder.

[0038] A preparation process for an aramid fiber clut...

Embodiment 2

[0047] An aramid fiber clutch face, made of the following raw materials in parts by weight: 1 part of nitrile rubber, 6 parts of glass fiber, 6 parts of aramid fiber, 6 parts of kapok fiber, 1 part of plant powder, 2 parts of graphite, carbon 3 parts of black, 2 parts of nano-silica, 4 parts of aluminum hydroxide, 1 part of zinc stearate, 10 parts of phenolic resin, and 0.5 parts of sulfur.

[0048] The weight ratio of glass fiber, aramid fiber and kapok fiber is 1:1:1.

[0049] The plant powder is made from the following raw materials in parts by weight: 1 part of peony bark.

[0050] The preparation process of plant powder is as follows:

[0051] (1): Pulverize 1 part of Moutan Cortex and pass through a 60-80 mesh sieve for later use;

[0052] (2): Add 8 parts by weight of ethanol into the cortex moutan powder obtained in step (1), stir for 5 minutes and put it into a drying machine to dry to obtain a plant powder.

[0053] A preparation process for an aramid fiber clutch...

Embodiment 3

[0062] An aramid fiber clutch face, made of the following raw materials in parts by weight: 2 parts of nitrile rubber, 8 parts of glass fiber, 8 parts of aramid fiber, 8 parts of kapok fiber, 2 parts of plant powder, 4 parts of graphite, carbon 5 parts of black, 4 parts of nano-silica, 6 parts of aluminum hydroxide, 3 parts of zinc stearate, 13 parts of phenolic resin, and 0.5 part of sulfur.

[0063] The weight ratio of glass fiber, aramid fiber and kapok fiber is 1:1:1.

[0064] The plant powder is made from the following raw materials in parts by weight: 2 parts of peony bark.

[0065] The preparation process of plant powder is as follows:

[0066] (1): Pulverize 2 parts of Moutan Cortex and pass through a 60-80 mesh sieve for later use;

[0067] (2): Add 8 parts by weight of ethanol into the cortex moutan powder obtained in step (1), stir for 5 minutes and put it into a drying machine to dry to obtain a plant powder.

[0068] A preparation process for an aramid fiber cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com