Low-temperature burning preparation method and positive electrode material of spinel lithium nickel manganese oxide

A lithium nickel manganese oxide, low-temperature combustion technology, applied in nanotechnology for materials and surface science, battery electrodes, electrical components, etc., can solve the problem of full combustion of the gel system, low synthesis temperature, and low yield of combustion products, etc. problems, to achieve the effect of sufficient crystal growth, low ignition temperature and short calcination time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

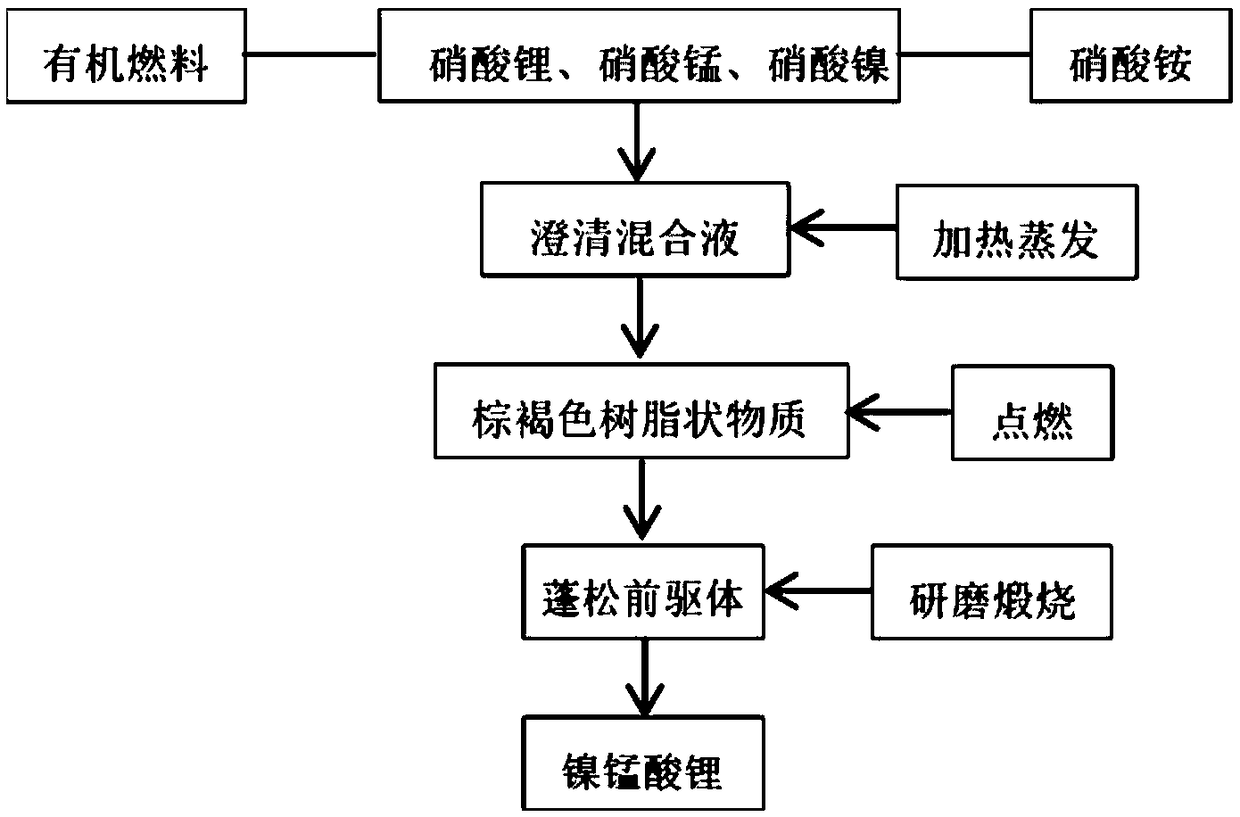

[0027] This embodiment provides a low-temperature combustion preparation method of spinel lithium nickel manganese oxide, the steps comprising:

[0028] (1) Lithium nitrate, nickel nitrate, manganese nitrate, citric acid and ammonium nitrate are dissolved in 100ml deionized water and mixed evenly according to the molecular molar ratio of 1:0.5:1.5:3:7, and the pH value of the solution is adjusted by ammonia water to 7;

[0029] (2) heating up to 90°C to evaporate and lose water, gradually viscous, and obtain a resinous substance;

[0030] (3) Raise the temperature to about 200°C, ignite and burn to obtain a fluffy and brittle precursor;

[0031] (4) The product was ground and loaded into a muffle furnace, calcined at 800° C. for 6 hours in an air atmosphere, and then cooled with the furnace to obtain a cathode material of spinel lithium nickel manganese oxide.

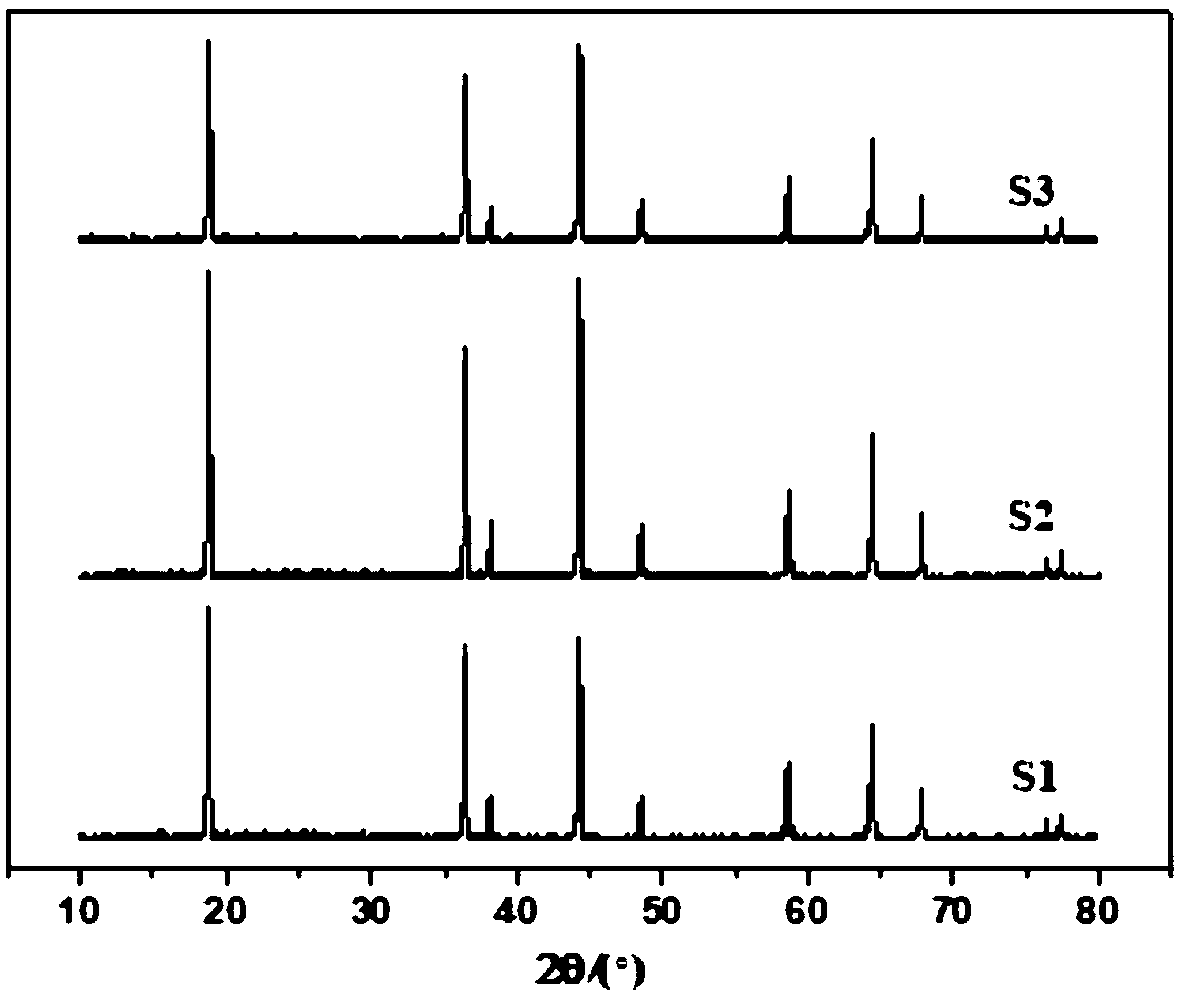

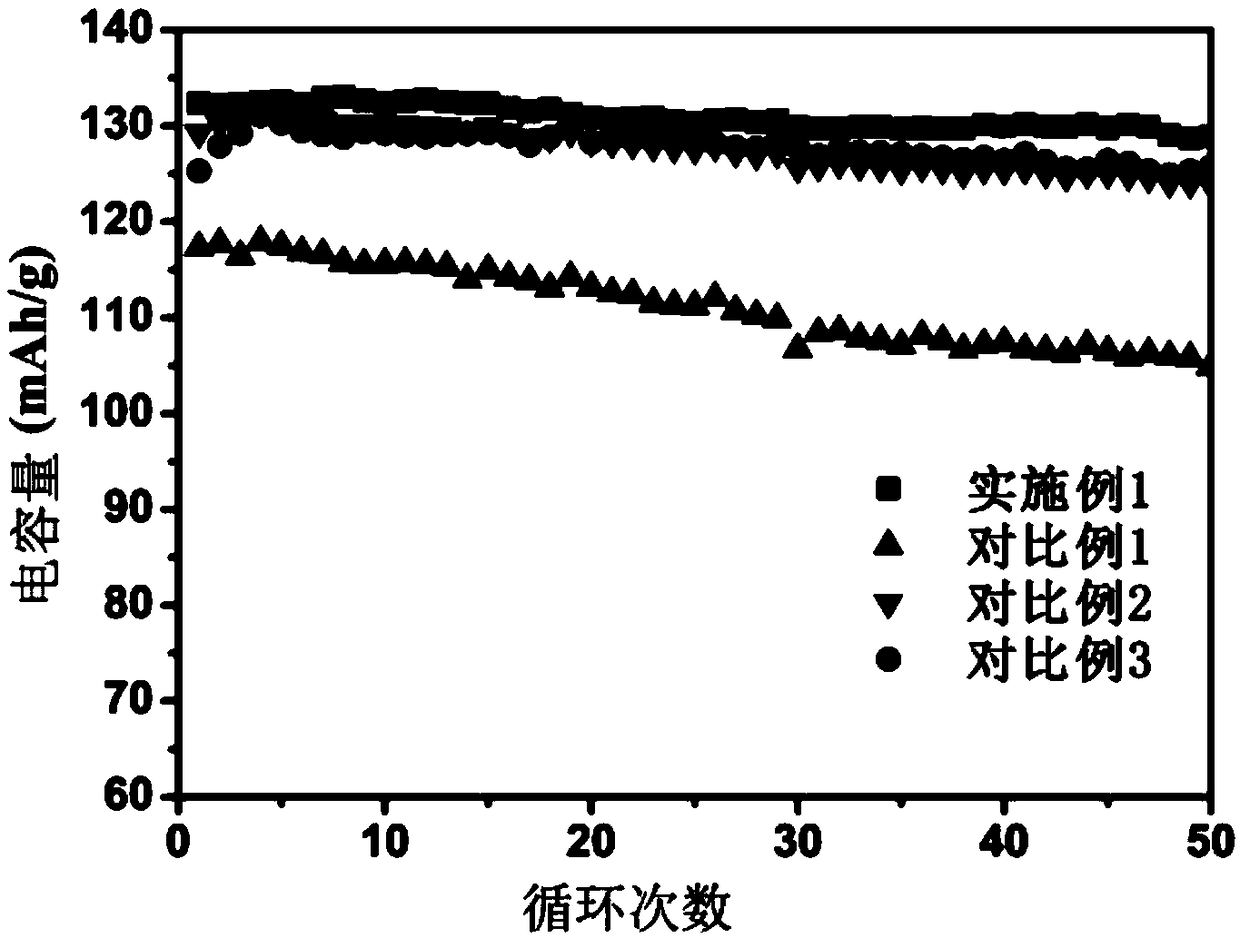

[0032] Such as figure 2 As shown in S1 in the X-ray diffraction diagram, the analysis results show that the powde...

Embodiment 2

[0034] This embodiment provides a low-temperature combustion preparation method of spinel lithium nickel manganese oxide, the steps comprising:

[0035] (1) Lithium nitrate, nickel nitrate, manganese nitrate, acrylic acid and ammonium nitrate are dissolved in 100ml deionized water at a molecular molar ratio of 1:0.5:1.5:4.5:28 and mixed evenly, and the pH value of the solution is adjusted by ammonia water to 7;

[0036] (2) Heat up to 95°C to evaporate and lose water, gradually become viscous, and obtain a resinous substance;

[0037] (3) Raise the temperature to about 200°C, ignite and burn to obtain a fluffy and brittle precursor;

[0038] (4) The product was ground and put into a crucible, calcined at 700° C. for 12 hours in an air atmosphere, and then cooled with the furnace to obtain a cathode material of spinel lithium nickel manganese oxide.

[0039] Such as figure 2 As shown in S2 in the X-ray diffraction diagram, the analysis results show that the powder is spinel-...

Embodiment 3

[0041] This embodiment provides a low-temperature combustion preparation method of spinel lithium nickel manganese oxide, the steps comprising:

[0042] (1) Lithium nitrate, nickel nitrate, manganese nitrate, glycine and ammonium nitrate are dissolved in 100ml deionized water and mixed evenly according to the molecular molar ratio of 1:0.5:1.5:6:42, and the pH value of the solution is adjusted by ammonia water to 7;

[0043] (2) Heat up to 100°C to evaporate and lose water, gradually become viscous, and obtain a resinous substance;

[0044] (3) Raise the temperature to about 200°C, ignite and burn to obtain a fluffy and brittle precursor;

[0045] (4) The product was ground and put into a crucible, calcined at 900° C. for 4 hours in an air atmosphere, and then cooled with the furnace to obtain a cathode material of spinel lithium nickel manganese oxide.

[0046] Such as figure 2 As shown in S3 in the X-ray diffraction diagram, the analysis results show that the powder is sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com