Preparation method of slow-release tilmicosin microcapsule powder

A technology of tilmicosin and microcapsule powder, which is applied in the field of preparation of sustained-release tilmicosin microcapsule powder, can solve problems affecting palatability, animal stimulation, and affecting the popularization and application of tilmicosin, and achieves improved palatability Sex, smooth release process, good taste-masking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

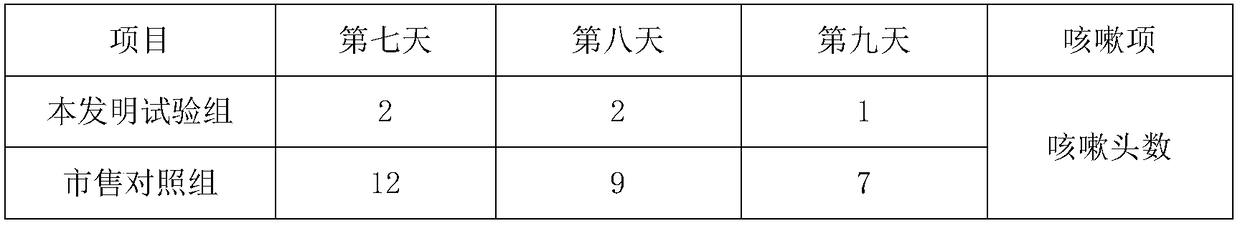

Examples

Embodiment 1

[0025] A preparation method for sustained-release tilmicosin microcapsule powder, comprising the following steps:

[0026] Step 1, dissolve 200g of acrylic acid in 1700g of water, adjust the pH of the solution to neutral, then add 400g of starch and 60g of hypromellose, heat up to 50°C, stir to dissolve, then add 400g of tilmicosin raw materials and 20g of chlorinated Calcium, stirring and mixing to obtain mixed solution 1;

[0027] Step 2, add 10.9g of polyethylene glycol 400 and 109g of sodium polyacrylate to the mixed solution 1, stir and dissolve, and then carry out high-pressure homogenization by a homogenizer with a homogenization pressure of 30MPa to obtain a homogeneous solution;

[0028] Step 3, drop 1450 g of sodium alginate aqueous solution with a mass percentage concentration of 10% into the homogeneous liquid under the stirring condition of a stirring speed of 200 rpm, and continue stirring for 40 minutes to obtain a mixed liquid;

[0029] In step 4, the mixed so...

Embodiment 2

[0031] A preparation method for sustained-release tilmicosin microcapsule powder, comprising the following steps:

[0032] Step 1, dissolve 250g of acrylic acid in 2522g of water, adjust the pH of the solution to neutral, then add 500g of starch and 80g of hypromellose, heat up to 53°C, stir to dissolve, then add 500g of tilmicosin raw materials and 28g of chlorinated Calcium, stirring and mixing to obtain mixed solution 1;

[0033] Step 2, add 31g of polyethylene glycol 400 and 232.8g of sodium polyacrylate into the mixed solution 1, stir and dissolve, and then carry out high-pressure homogenization through a homogenizer, with a homogenization pressure of 35MPa, to obtain a homogeneous solution;

[0034] Step 3: Drop 2072 g of a sodium alginate aqueous solution with a concentration of 12% by mass into the homogeneous liquid under the stirring condition of a stirring speed of 230 rpm, and continue stirring for 45 minutes to obtain a mixed liquid;

[0035] In step 4, the mixed...

Embodiment 3

[0037] A preparation method for sustained-release tilmicosin microcapsule powder, comprising the following steps:

[0038] Step 1, dissolve 280g of acrylic acid in 2455g of water, adjust the pH of the solution to neutral, then add 550g of starch and 70g of hypromellose, raise the temperature to 57°C, stir to dissolve, then add 570g of tilmicosin raw materials and 35g of chlorinated Calcium, stirring and mixing to obtain mixed solution 1;

[0039] Step 2, add 39.6g of polyethylene glycol 400 and 277g of sodium polyacrylate into the mixed solution 1, stir and dissolve, and then carry out high-pressure homogenization through a homogenizer with a homogenization pressure of 40MPa to obtain a homogeneous solution;

[0040] Step 3: Drop 2138 g of a sodium alginate aqueous solution with a concentration of 13% by mass into the homogeneous liquid under the stirring condition of a stirring speed of 240 rpm, and continue stirring for 48 minutes to obtain a mixed liquid;

[0041] In step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com