Composite functional material for building interior and preparation process thereof

A technology of composite function and preparation process, applied in the field of materials, can solve the problems of poor heat preservation, no flame retardant function, heavy weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

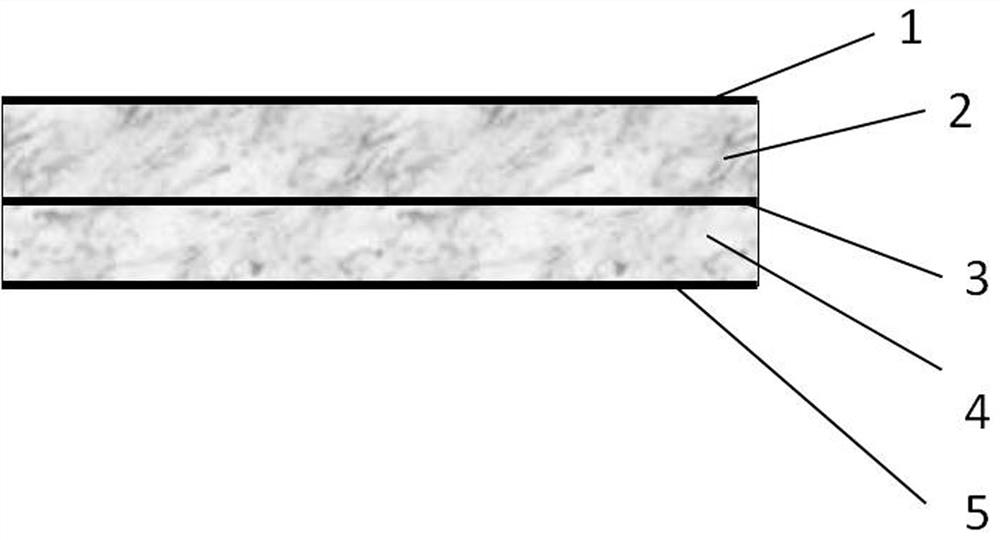

[0034] A composite functional material for building interiors, which consists of a material body and a non-woven fabric, and the non-woven fabric and the material body are stacked alternately layer by layer in a sandwich structure ( figure 1 shown); the main body of the material is made of the following components in parts by weight: 12 parts of modified diatomite, 10 parts of fly ash, 4 parts of calcium hydroxide, 5 parts of chopped carbon fiber, sepiolite 3 parts of velvet, 6 parts of starch-based porous carbon material, 2 parts of expanded perlite, 16 parts of modified cellulose aerogel, 1 part of modified layered dihydroxy composite hydrotalcite, and 12 parts of polyvinyl alcohol; the nonwoven The cloth is made of hemp fiber and shape-setting phase-change fiber in a mass ratio of 3:1.

[0035] Further, the shape-setting phase-change fiber is a ternary eutectic of fatty acids, namely LA (lauric acid)-PA (palmitic acid)-SA (fatty acid) with a mass ratio of 6:2:2 loaded onto ...

Embodiment 2

[0045] A composite functional material for building interiors, which consists of a material body and a non-woven fabric, and the non-woven fabric and the material body are stacked alternately layer by layer in a sandwich structure ( figure 1 shown); the main body of the material is made of the following components in parts by weight: 18 parts of modified diatomite, 14 parts of fly ash, 6 parts of calcium hydroxide, 7 parts of chopped carbon fiber, sepiolite 5 parts of velvet, 9 parts of starch-based porous carbon material, 5 parts of expanded perlite, 19 parts of modified cellulose airgel, 2 parts of modified layered dihydroxy composite hydrotalcite, and 16 parts of polyvinyl alcohol; the nonwoven The cloth is made of hemp fiber and shape-setting phase-change fiber in a mass ratio of 3.5:1.

[0046] Further, the shape-setting phase-change fiber is a ternary eutectic of fatty acids, namely LA (lauric acid)-PA (palmitic acid)-SA (fatty acid) with a mass ratio of 6:2:2 loaded ont...

Embodiment 3

[0056] A composite functional material for building interiors, which consists of a material body and a non-woven fabric, and the non-woven fabric and the material body are stacked alternately layer by layer in a sandwich structure ( figure 1 shown); the main body of the material is made of the following components in parts by weight: 23 parts of modified diatomite, 18 parts of fly ash, 6 parts of calcium hydroxide, 12 parts of chopped carbon fiber, sepiolite 7 parts of velvet, 14 parts of starch-based porous carbon material, 6 parts of expanded perlite, 23 parts of modified cellulose aerogel, 2.5 parts of modified layered dihydroxy composite hydrotalcite, and 18 parts of polyvinyl alcohol; the nonwoven The cloth is made of hemp fiber and shape-setting phase-change fiber in a mass ratio of 3.8:1.

[0057] Further, the shape-setting phase-change fiber is a ternary eutectic of fatty acids, namely LA (lauric acid)-PA (palmitic acid)-SA (fatty acid) with a mass ratio of 6:2:2 loade...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com