Nano small peptide chelated iron for feed additive and preparation method of nano small peptide chelated iron

A feed additive and small peptide chelation technology, which is applied in the preparation method of peptides, animal feed, chemical instruments and methods, etc., can solve the problems of iron element absorption and pollution of the environment, and achieve the improvement of nutritional functionality and biological potency, Effects of cost reduction and immunity enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

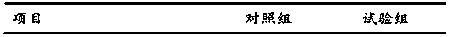

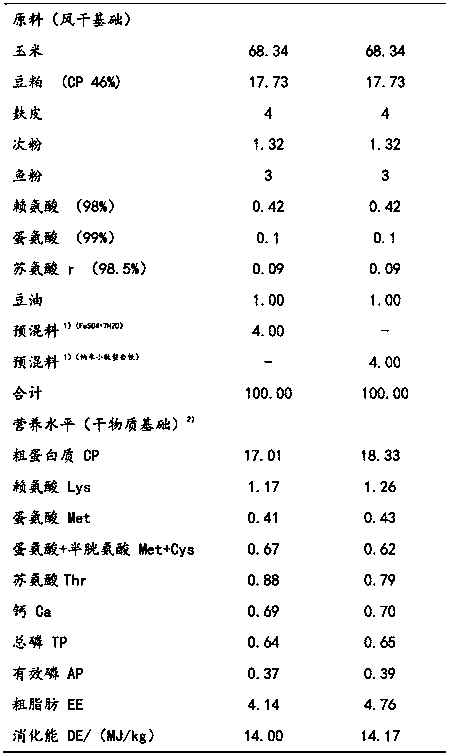

Examples

preparation example Construction

[0029] A kind of preparation method of the nano small peptide chelated iron that is used for feed additive, comprises the steps:

[0030] [1] Dissolving soybean meal powder: dissolving soybean meal powder in a buffer solution with pH=2.2-8.0 to obtain a soybean meal powder solution;

[0031] [2] Preparation of dry peptide powder: heat-treat the soybean meal powder solution obtained in step [1], then add alkaline protease and flavor protease, heat for enzymolysis, then inactivate the enzyme activity in a boiling water bath, centrifugally filter to obtain the enzymolysis solution, and dry to obtain dry peptide powder. peptide powder;

[0032] [3] Preparation of nanometer small peptide chelated iron: dissolve the dry peptide powder obtained in step [2] to obtain a small peptide solution, add inorganic ferrous solution under heating and stirring conditions, and make the small peptide react with iron to form a chelate, After separation and drying, the nanometer small peptide chela...

Embodiment 1

[0045] A preparation method for feed additive nano small peptide chelated iron, comprising the steps of:

[0046] (1) Preparation of buffer solution: 1000 mL of buffer solution with pH 2.2-8.0 was prepared with 0.2M disodium hydrogen phosphate and 0.1M citric acid.

[0047] (2) Preparation of dry peptide powder: Dissolve 155g of soybean meal powder (particle size ≤0.6mm) in 1000ml of buffer solution, adjust the pH value to 4.3, acid-treat at 35-40°C for 10min; then heat-treat at 89-90°C 15min; then place the enzyme on a constant temperature shaker under the conditions that the mass ratio of alkaline protease to flavor protease is 1:1, the temperature is kept at 50-55°C, the pH is 7.0, and the enzyme concentration (M / S) is 10.5%. After hydrolysis for 4 hours, inactivate the enzyme in a boiling water bath for 10 minutes, adjust the pH value to 4-4.5, then centrifuge at 3000 r / min for 10 minutes, filter to obtain the enzymatic hydrolysis solution, and spray dry to obtain dry pept...

Embodiment 2

[0053] A preparation method of feed additive nano small peptide chelated iron, the specific steps are as follows:

[0054] (1) Preparation of buffer solution: 0.2M disodium hydrogen phosphate and 0.1M citric acid were used to prepare a buffer solution with a pH of 2.2-8.0.

[0055] (2) Preparation of dry peptide powder: Dissolve soybean meal powder in the buffer solution of step (1) to make the concentration of soybean meal powder 165g / L, stir at 40-45°C for 15min; then heat-treat at 90-92°C for 20min; add Alkaline protease and flavor protease, at 55-60°C, pH=7.0, oscillating enzymolysis for 6 hours, after enzymolysis, inactivate the enzyme activity in a boiling water bath, adjust the pH value to 4.5, centrifuge, filter to obtain the enzymolysis solution, and dry , to obtain dry peptide powder;

[0056] (3) Preparation of small peptide solution: Dissolving dry peptide powder in water to make a saturated solution is small peptide solution;

[0057] (4) preparation of iron sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com