Electric furnace smelting method and system of full light scraps

A technology of electric furnace smelting and smelting method, which is applied in the field of electric furnace smelting method and smelting system of light and thin scrap steel, which can solve problems affecting smelting, eroding equipment, and unfavorable foam slag stability, so as to reduce equipment and personnel investment and improve energy utilization efficiency and the effect of reducing secondary waste pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0097] Embodiment (secret experiment)

[0098] The present invention will be further described by means of examples below, which are exemplary and not therefore limiting the present invention to the scope of the described examples. For the experimental methods that do not indicate specific conditions in the following examples, follow conventional methods and conditions.

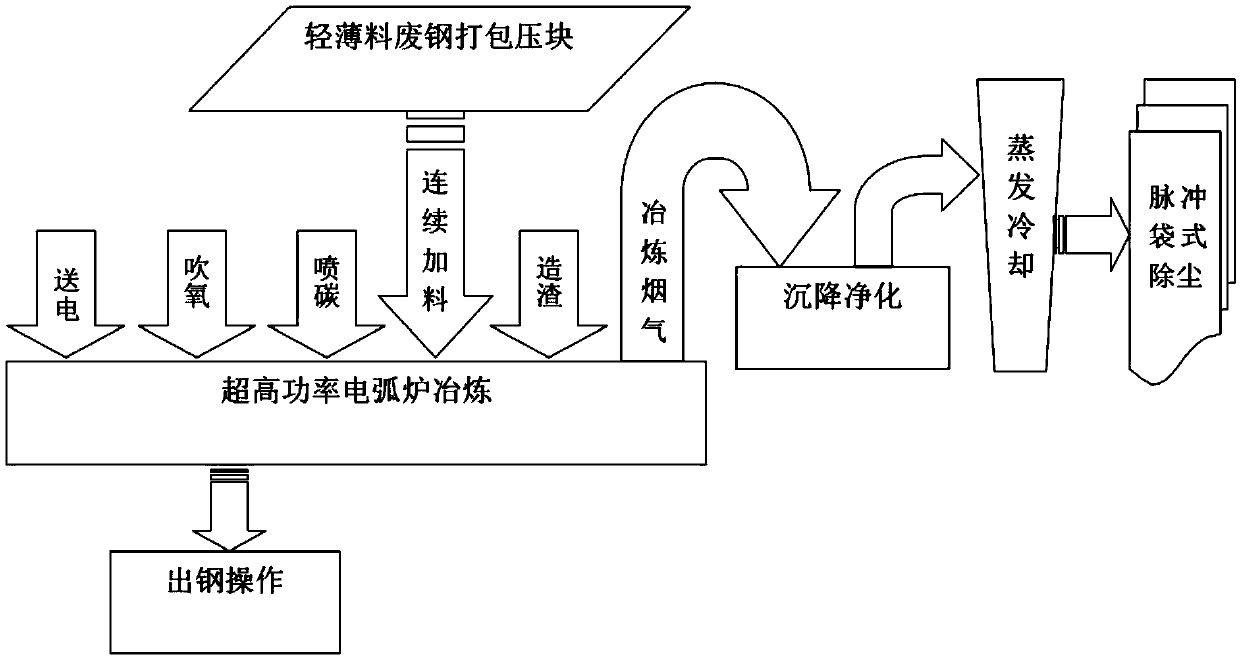

[0099] (1) Low-grade light and thin scrap steel such as color steel tiles, cans, and automobile panels does not need to be crushed, and is directly packed into large briquettes with a size of less than 2000×600×500mm by a baler.

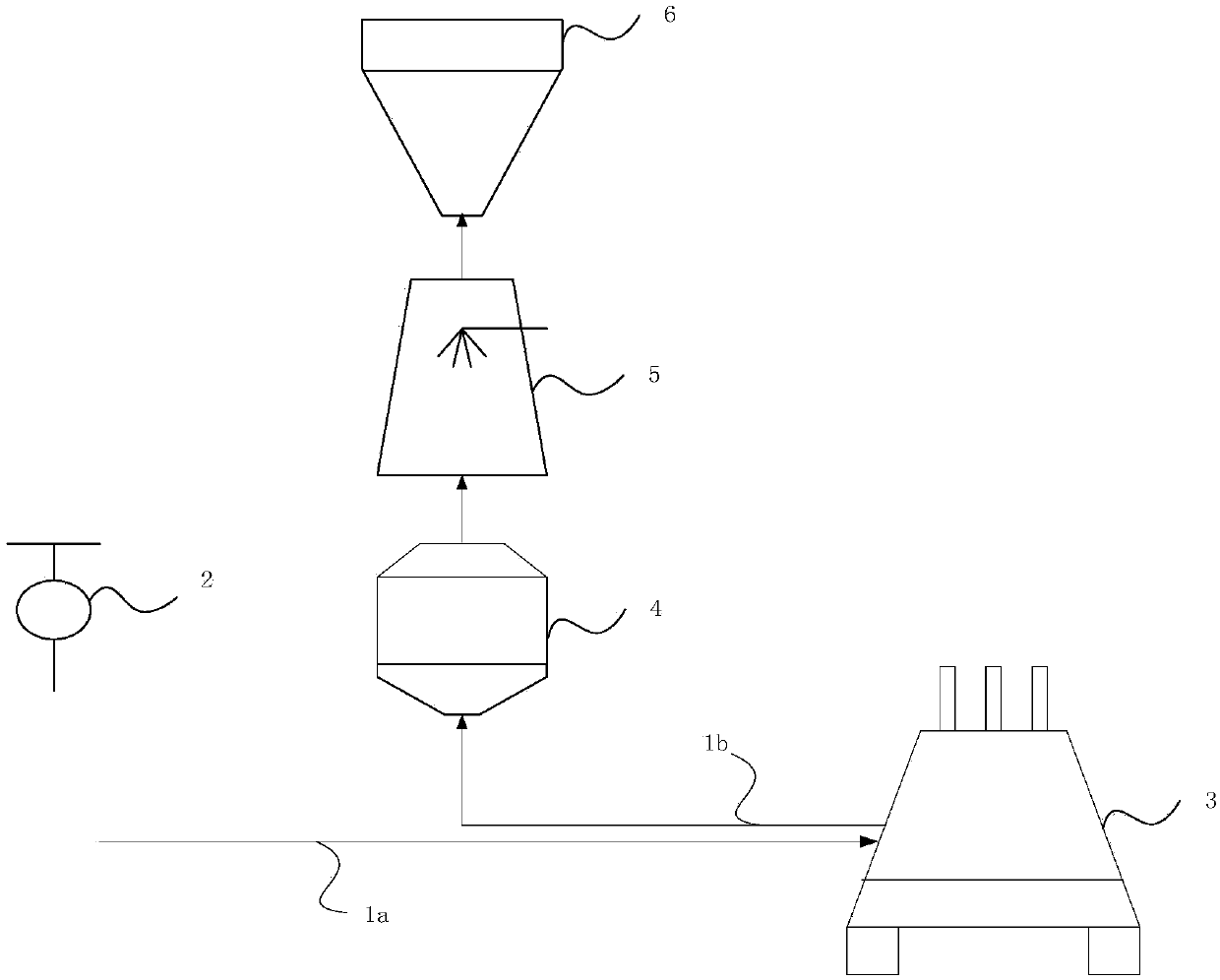

[0100] (2) Send the packaged scrap steel briquettes into the continuous feeding channel 1a through the spreader 2, and the continuous feeding channel 1a continuously feeds the briquettes into the 220-ton electric arc furnace at a rate of 4-5 tons / minute 3 (nominal capacity NC = 320 tons) for smelting.

[0101] (3) Carry out power transmission operation to the electric arc furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com