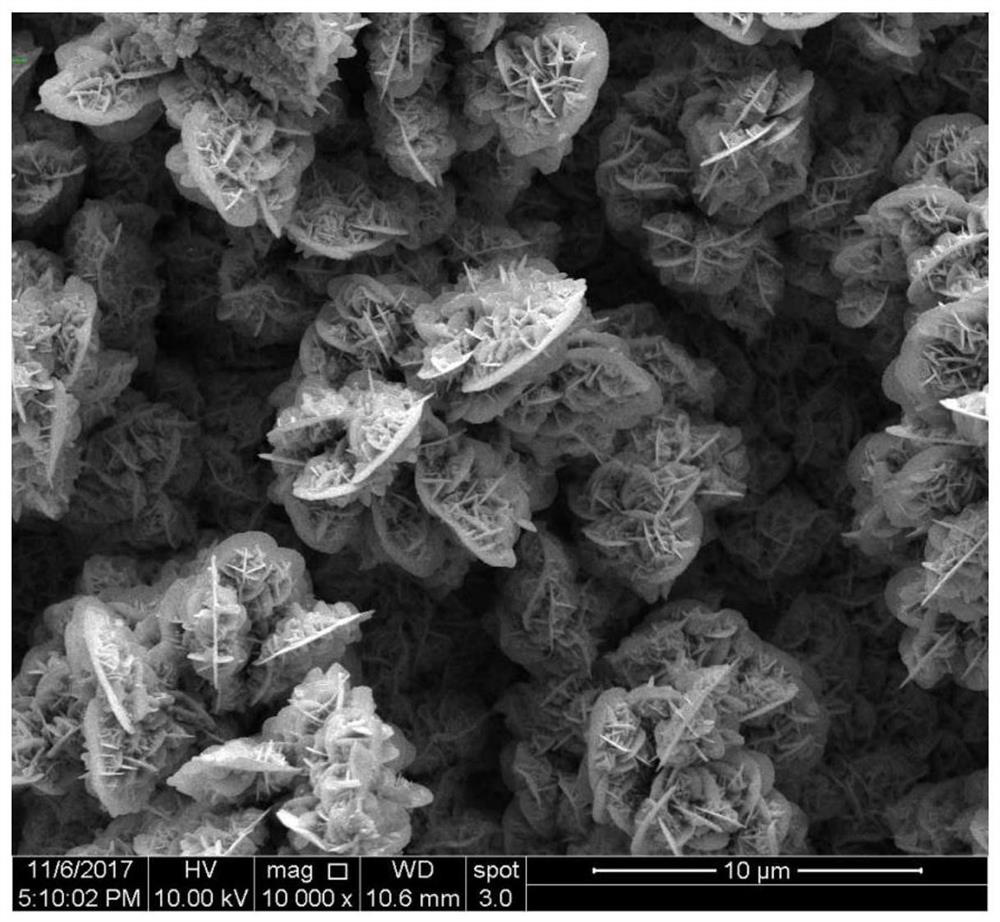

A kind of preparation method of porous flower flake lithium battery cathode material

A positive electrode material, lithium battery technology, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problems of high preparation cost, complicated preparation process, and inability to effectively inhibit polysulfide compounds , to achieve the effect of low preparation temperature, simple preparation method, and inhibition of the formation of polysulfides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a porous flower flake lithium battery positive electrode material, comprising the following steps:

[0032] (1) After polishing 0.1g copper foil (thickness 50μm) with No. 0-6 sandpaper in sequence, then ultrasonically clean it with acetone, absolute ethanol, and deionized water, and then put the copper foil into the reaction kettle; Copper chloride hydrate, 0.4g thiourea and 0.05g polyvinylpyrrolidone (PVP) are dissolved in the ethanol of 95% (v / v), make precursor solution, precursor solution is added reactor according to the amount of 60% of reactor volume middle;

[0033] (2) Use a pipette to transfer 1ml of aqueous carbon quantum dot solution with a concentration of 10mg / ml into the reaction kettle, and stir for 20min to mix the precursor solution and aqueous carbon quantum dots evenly;

[0034] (3) After sealing the reaction kettle, put it into a blast drying oven, heat it at 120°C for 5h, wash it with absolute ethanol three times, then wash ...

Embodiment 2

[0038] A method for preparing a porous flower flake lithium battery positive electrode material is prepared by the following steps:

[0039] (1) Soak 0.3g of copper foil (thickness 50μm) in sulfuric acid with a mass fraction of 25% and 3% for 3 minutes, then ultrasonically clean it with acetone, absolute ethanol, and deionized water, and then put the copper foil into the reaction kettle; 0.5g cupric chloride dihydrate, 0.4g thiourea and 0.8g PVP were dissolved in 95% ethanol to obtain a precursor solution, which was added to the reactor according to the amount of 80% of the reactor volume;

[0040] (2) Use a pipette to transfer 2ml of water-phase carbon quantum dot solution with a concentration of 20mg / ml into the reaction kettle, and stir for 60min to mix the precursor solution and water-phase carbon quantum dots evenly;

[0041] (3) After sealing the reaction kettle, put it into a blast drying oven, heat it at 220°C for 72h, wash it with absolute ethanol three times, then wa...

Embodiment 3

[0045] A method for preparing a porous flower flake lithium battery positive electrode material is prepared by the following steps:

[0046] (1) Soak 0.2g of copper foil (thickness 50μm) with 25% and 3% sulfuric acid for 3 minutes, then ultrasonically clean it with acetone, absolute ethanol, and deionized water in sequence, and then put the copper foil into the reaction kettle; 0.5g copper chloride dihydrate, 0.4g thiourea and 0.4g PVP were dissolved in 95% ethanol to prepare a precursor solution, and the precursor solution was added to the reactor according to 70% of the volume of the reactor;

[0047] (2) Use a pipette to transfer 1.5ml of aqueous carbon quantum dot solution with a concentration of 10mg / ml into the reaction kettle, and stir for 30min to mix the precursor solution and aqueous carbon quantum dots evenly;

[0048] (3) After sealing the reaction kettle, put it into a blast drying oven, heat it at 200°C for 12h, wash it with absolute ethanol three times, then was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com