Preparation method of microorganism ferment calcium effervescent tablets

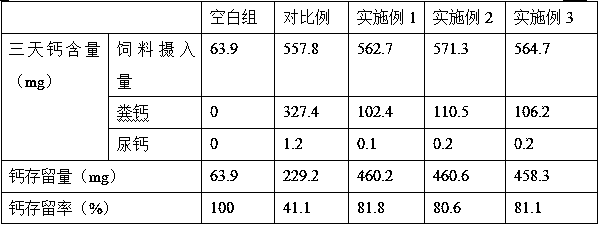

A technology of microorganisms and effervescent tablets, applied in the direction of bacteria used in food preparation, food science, and the function of food ingredients, can solve problems such as gastrointestinal hazards, low calcium absorption rate, and obvious side effects, so as to improve the utilization and absorption rate , Improve the utilization rate and promote the absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A preparation method for microbial enzyme calcium effervescent tablet, comprising the steps of:

[0023] (1) Take fresh sheep bones and add distilled water at a mass ratio of 2:1, keep at 120-125°C for 20-30 minutes, cool, take out the sheep bones to remove minced meat and bone marrow, dry them at 100-110°C for 5-6 hours, and crush them for 80 Mesh sieve, collect the sieved particles A, add absolute ethanol at a mass ratio of 1:5, keep at 25~30°C for 18~24h, and rotate to evaporate to obtain a rotary evaporated product, add alkaline protease at a dosage of 4~5% , hydrolyzed at 45~50°C for 6~7h to obtain the first-grade enzymatic hydrolyzate, added 3~4% of the first-grade enzymatic hydrolyzate to compound flavor protease, enzymolyzed at 50~55°C for 4~5h, 90 Inactivate the enzyme at ~95°C for 15-20 minutes, centrifuge, take the supernatant, adjust the pH to 7-7.3, and obtain the enzymatic hydrolysis solution;

[0024] (2) Dry the egg shell, crush it through a 100-mesh si...

Embodiment 1

[0030] Compound flavor protease: purchased from Enolink Biotechnology Development (Beijing) Co., Ltd.

[0031] Casein powder: purchased from Chengdu Kelong Chemical Reagent Factory.

[0032] Saccharomyces cerevisiae powder: purchased from Hubei Angel Yeast Co., Ltd.; Lactobacillus casei powder: purchased from Inner Mongolia Puze Biological Products Co., Ltd.

[0033] A preparation method for microbial enzyme calcium effervescent tablet, comprising the steps of:

[0034] (1) Take fresh sheep bones and add distilled water at a mass ratio of 2:1, keep at 120°C for 20 minutes, cool, take out the sheep bones to remove minced meat and bone marrow, dry at 100°C for 5 hours, crush them through an 80-mesh sieve, and collect the sieved particles A , add absolute ethanol at a mass ratio of 1:5, keep at 25°C for 18h, and rotate to evaporate to obtain a rotary evaporate, add alkaline protease at 4% addition amount, and enzymolyze at 45°C for 6h to obtain a first-grade enzymatic hydrolyzat...

Embodiment 2

[0041] Compound flavor protease: purchased from Enolink Biotechnology Development (Beijing) Co., Ltd.

[0042] Casein powder: purchased from Chengdu Kelong Chemical Reagent Factory.

[0043] Saccharomyces cerevisiae powder: purchased from Hubei Angel Yeast Co., Ltd.; Lactobacillus casei powder: purchased from Inner Mongolia Puze Biological Products Co., Ltd.

[0044] A preparation method for microbial enzyme calcium effervescent tablet, comprising the steps of:

[0045] (1) Take fresh sheep bones and add distilled water at a mass ratio of 2:1, keep at 123°C for 25 minutes, cool down, take out the sheep bones to remove minced meat and bone marrow, dry at 105°C for 5.5 hours, crush them through an 80-mesh sieve, and collect the sieved particles A. Add absolute ethanol at a mass ratio of 1:5, keep at 28°C for 20 hours, and rotate to evaporate to obtain a rotary evaporated product. Add alkaline protease at a dosage of 4.5%, and enzymolyze at 48°C for 6.5 hours to obtain a first-g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com