Environment-friendly and efficient refining agent for cotton and preparation method thereof

A scouring agent, an environmentally friendly technology, applied in the field of textile printing and dyeing, can solve the problems of poor cotton fabrics, etc., and achieve the effects of excellent emulsifying ability, rich foam, strong salt resistance and hard water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

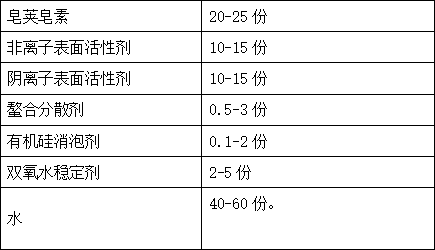

Method used

Image

Examples

Embodiment 1

[0034] In the present embodiment, an environmentally friendly and high-efficiency scouring agent for cotton is provided, which includes the following components in parts by weight: 20 parts of saponin, 11 parts of lauryl fatty alcohol polyoxyethylene ether, succinic acid bis(2 -ethylhexyl ester) sodium sulfonate 11 parts, sodium gluconate 1 part, polyether modified silicone defoamer 1 part, sodium silicate 2 parts, water 54 parts.

[0035] The present invention also provides a preparation method of an environmentally friendly and efficient scouring agent for cotton, the specific steps are as follows:

[0036] (1) Add 54 parts of deionized water into the reaction kettle, heat up to 75°C, add 20 parts of saponin and 11 parts of lauryl fatty alcohol polyoxyethylene ether, and stir for 20 minutes at a speed of 600 rpm to complete uniformity;

[0037] (2) Add 11 parts of sodium bis(2-ethylhexyl)sulfosuccinate, and stir for 10 minutes at a speed of 500 rpm until completely uniform;...

Embodiment 2

[0043]In the present embodiment, an environmentally friendly and high-efficiency scouring agent for cotton is provided, which includes the following components in parts by weight: 25 parts of saponin, 10 parts of lauryl fatty alcohol polyoxyethylene ether, succinic acid bis(2 -ethylhexyl ester) sodium sulfonate 15 parts, ethylenediamine tetraacetate 3 parts, polyether modified silicone defoamer 2 parts, sodium silicate 5 parts, water 40 parts.

[0044] The present invention also provides a preparation method of an environmentally friendly and efficient scouring agent for cotton, the specific steps are as follows:

[0045] (1) Add 40 parts of deionized water into the reaction kettle, heat up to 80°C, add 25 parts of saponin and 10 parts of lauryl fatty alcohol polyoxyethylene ether, and stir for 30 minutes at a speed of 500 rpm to complete uniformity;

[0046] (2) Add 15 parts of bis(2-ethylhexyl) sodium sulfosuccinate, and stir for 8 minutes at a speed of 400 rpm until comple...

Embodiment 3

[0052] In this embodiment, an environmentally friendly and efficient scouring agent for cotton is provided, which includes the following components in parts by weight: 22 parts of saponin, 13 parts of lauryl fatty alcohol polyoxyethylene ether, di(2) succinic acid -ethylhexyl ester) sodium sulfonate 15 parts, sodium gluconate 2 parts, polyether modified silicone defoamer 1 part, sodium silicate 1 part, sodium sulfate 1 part, water 45 parts.

[0053] The present invention also provides a preparation method of an environmentally friendly and efficient scouring agent for cotton, the specific steps are as follows:

[0054] (1) Add 45 parts of deionized water into the reaction kettle, raise the temperature to 78°C, add 22 parts of saponin and 13 parts of lauryl fatty alcohol polyoxyethylene ether, and stir for 20 minutes at a speed of 550 rpm to complete uniformity;

[0055] (2) Add 15 parts of bis(2-ethylhexyl) sodium sulfosuccinate, and stir for 8 minutes at a speed of 450 rpm u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com