Preparation method of microencapsulated fish oil milk sugar

A technology of microencapsulation and microencapsulation, which is used in confectionery, confectionery industry, food forming and other directions, can solve the problems of low nutritional value, no health care effect, and high sugar content, achieve high bioavailability, improve biological Utilization, good absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

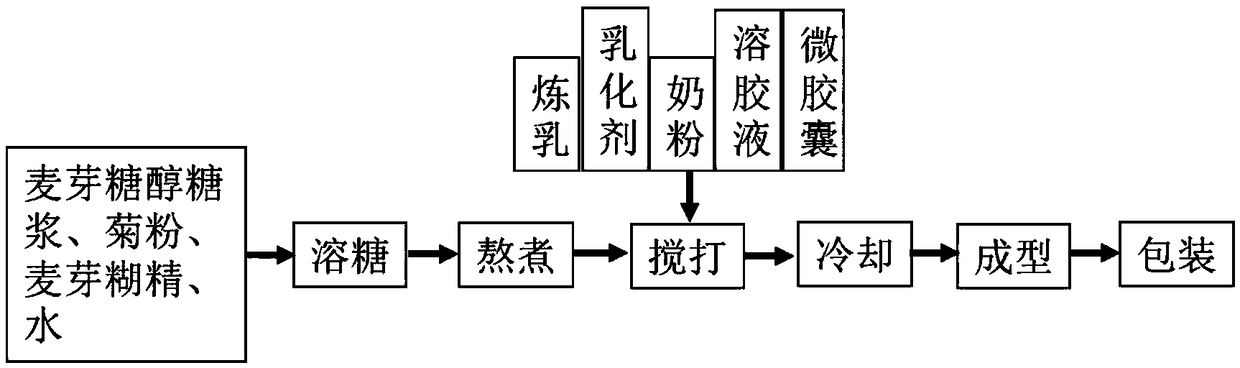

Method used

Image

Examples

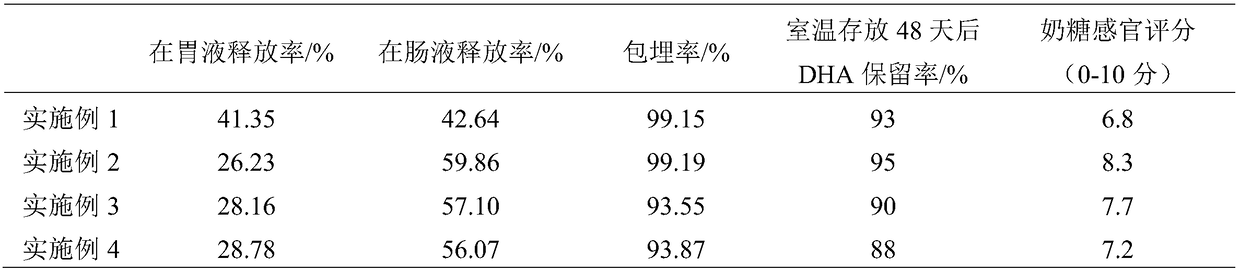

Embodiment 1

[0021] (1) Stir and dissolve 17kg of triglyceride-type fish oil, 0.1kg of natural vitamin E and 1.2kg of mono- and diglycerides, and make A liquid;

[0022] Take 180kg of purified water, heat it to 80-85°C, add 15kg of starch octenyl succinate, 5kg of gum arabic, 43.5kg of polydextrose, and 0.5kg of propylene glycol alginate in sequence, stir to dissolve, and make B liquid;

[0023] (2) Under the environment of 60-62°C and a stirring speed of 1300r / min, pour liquid A into liquid B at a constant speed, and continue to stir for 8-10 minutes. The time taken for liquid A to pour into liquid B at a constant speed is 6 minutes; The mixed solution was subjected to homogeneous emulsification for 3 times, the first homogenization pressure was 35MPa, and the second and third homogenization pressures were 50MPa; the homogenized emulsion obtained was spray-dried to obtain fish oil microcapsules, and the spray-drying inlet air temperature is 180°C, and the outlet air temperature is 80°C. ...

Embodiment 2

[0029](1) With triglyceride type fish oil 17kg, slow-release stabilizer 13kg, natural vitamin E0.1kg and mono-diglyceride 1.2kg, stir and dissolve, be made into A liquid; The preparation method of described slow-release stabilizer is as follows: 1 ) dissolving 5kg of konjac starch in 8kg of water, adjusting the pH to 5.3-5.5, heating and stirring until the starch is completely gelatinized, cooling to 53-56°C, adding 160-163ml of pullulanase with an enzyme activity of 280-290u / ml, Enzymatically debranch at 53-56°C for 20-22 hours. After the reaction, inactivate the enzyme and dry to obtain konjac linear dextrin; 2) Slowly add 2 kg of polyethylene glycol, 2 kg of ethanol, and 1 kg of methanol to the konjac linear dextrin , stirred at 24-26°C for 28-30min, settled at 3-4°C for 20-22h, and centrifuged to obtain filter cake A; 3) Add 1.5kg of polyethylene glycol and isopropanol to filter cake A 1.5kg, ethanol 1.5kg, stirred at 24-26°C for 25-28min, settled at 3-4°C for 20-22h, and ...

Embodiment 3

[0037] (1) With triglyceride type fish oil 17kg, slow-release stabilizer 13kg, natural vitamin E0.1kg and mono-diglyceride 1.2kg, stir and dissolve, be made into A liquid; The preparation method of described slow-release stabilizer is as follows: 1 ) dissolving 5kg of konjac starch in 8kg of water, adjusting the pH to 5.3-5.5, heating and stirring until the starch is completely gelatinized, cooling to 53-56°C, adding 160-163ml of pullulanase with an enzyme activity of 280-290u / ml, Enzymatically debranch at 53-56°C for 20-22 hours. After the reaction, inactivate the enzyme and dry to obtain konjac linear dextrin; 2) Slowly add 2 kg of polyethylene glycol, 2 kg of ethanol, and 1 kg of methanol to the konjac linear dextrin , stirred at 24-26°C for 28-30min, settled at 3-4°C for 20-22h, and centrifuged to obtain filter cake A; 3) Add 1.5kg of polyethylene glycol and isopropanol to filter cake A 1.5kg, ethanol 1.5kg, stirred at 24-26°C for 25-28min, settled at 3-4°C for 20-22h, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com