Corn stick and corn cob wrapping technology

A corncob and corncob technology, applied in the field of wrapped silage, can solve the problems of inability to absorb and utilize, poor taste, long fermentation period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

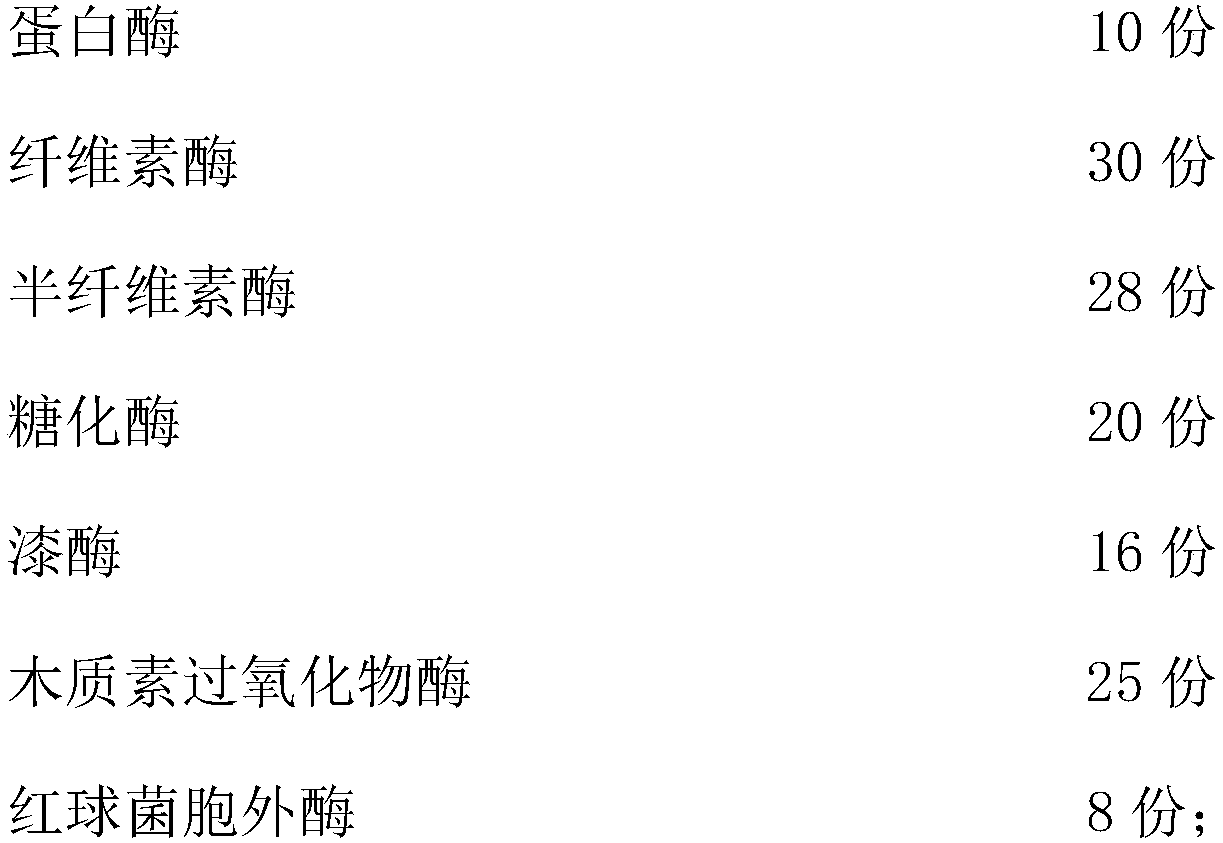

Embodiment 1

[0028] Step 1: crushing corn cobs and corn cobs, passing through a 100-mesh sieve, and then adding 15% soybean powder to obtain a mixed raw material;

[0029] Step 2: Add water into the mixed raw materials according to the material-water ratio of 1:1, and mix evenly with 7% compound enzyme with an enzyme activity of 5000-6000U / g, preheat at 30°C for 0.5h, and then heat up to 40°C ℃ water bath for 3 hours to obtain the hydrolyzed puree;

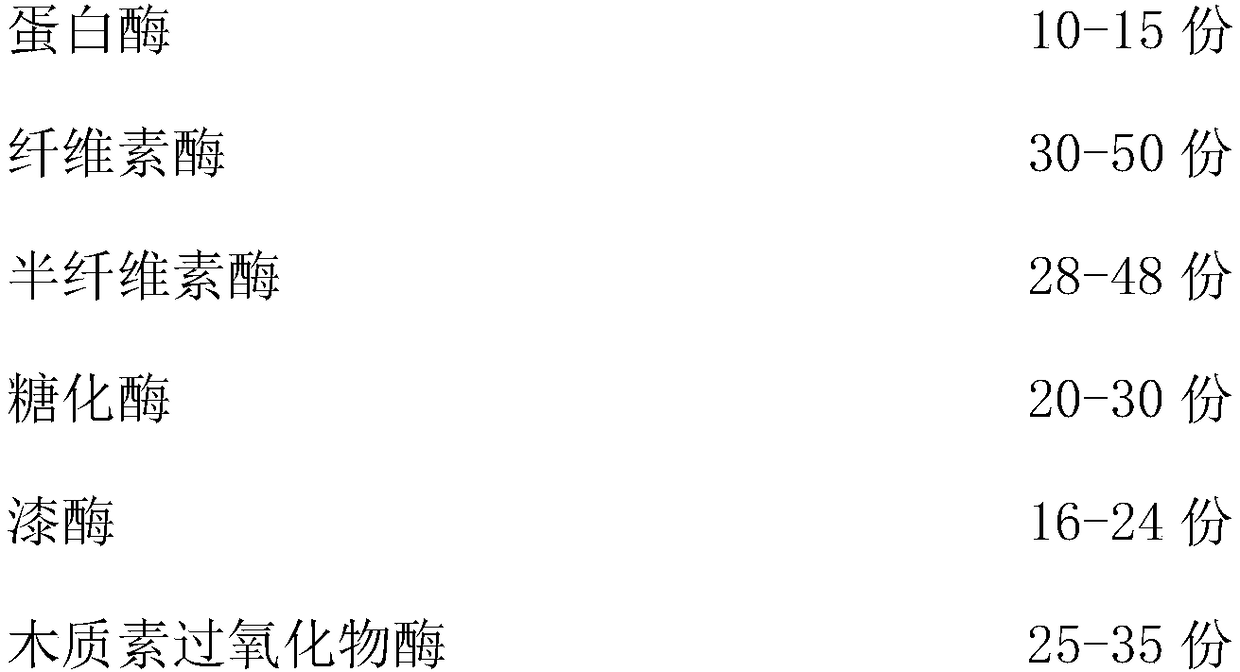

[0030] Wherein, the composite enzyme includes the following components in parts by weight:

[0031]

[0032] Step 3: Mix 0.6% sodium sorbate and 10% EM bacteria into the hydrolyzed puree, and stir for 30 minutes every 6 hours at 35°C under the condition of oxygenation, and after 3 days of fermentation, dehydrate and dry until the dry matter content is 45% , to obtain the first fermented product;

[0033] Step 4: Inoculate Ruminococcus xanthophyllum, Ruminococcus albicans, Filamentous bacteria succinogenes, Lactobacillus casei, and Sacchar...

Embodiment 2

[0035] The operation is the same as in Example 1, wherein, step 1, mesh number: 125, soybean powder: 20%, soybean powder; step 2, material-to-water ratio: 1.5:1, compound enzyme: 8%, 6000-7000U / g, preheat : 33°C, 0.75h, water bath: 45°C, 4h, parts by weight of the components of the compound enzyme: 13 parts, 40 parts, 39 parts, 25 parts, 20 parts, 30 parts, 10 parts; Step 3, antifungal agent: 0.8%, sodium benzoate, EM bacteria: 13%, fermentation: 36°C, 4d, intermittent stirring: every 9h, stirring for 40min; Step 4, the mass ratio of the components of the anaerobic fermentation agent is 2.3:2.1:1.6:2.5: 3. Anaerobic starter dosage: 6%, fermentation: 40°C, 13 days, number of wrapping layers: 5, stack height: 25cm.

Embodiment 3

[0037] The operation is the same as in Example 1, wherein, step 1, mesh number: 150, bean flour: 25%, pea flour; step 2, material-to-water ratio: 2:1, compound enzyme: 9%, 7000-8000U / g, preheat : 35°C, 1h, water bath: 50°C, 5h, parts by weight of each component of the compound enzyme: 15 parts, 50 parts, 48 parts, 30 parts, 24 parts, 35 parts, 12 parts; Step 3, antifungal agent: 1 %, dimethyl fumarate, EM bacteria: 15%, fermentation: 37°C, 5d, intermittent stirring: every 12h, stirring for 50min; step 4, the mass ratio of the components of the anaerobic fermentation agent is 2.5:2.3:1.5 : 3: 2.5, dosage of anaerobic fermentation agent: 7%, fermentation: 42°C, 15 days, number of wrapping layers: 6, stack height: 30cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com