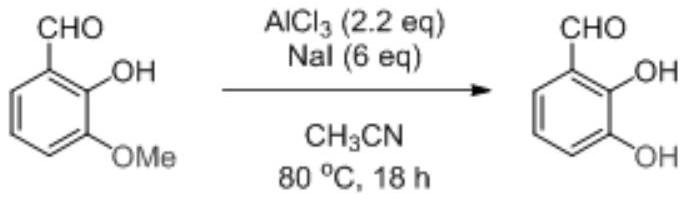

A kind of method for preparing 2,3-dihydroxybenzaldehyde by removing the methyl group of o-vanillin

A technology of dihydroxybenzaldehyde and o-vanillin, which is applied to the preparation of carbon-based compounds, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of low yield, high preparation cost, and inconvenient operation. Achieve the effects of simple reaction purification operation, wide range of sources and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020]

[0021] Acetonitrile (40ml), aluminum chloride (0.804g, 6.03mmol, 1.1eq), NaI (2.464g, 16.44mmol, 3.0eq) and o-vanillin (0.417g, 2.74mmol) were added to a 100ml eggplant-shaped flask ), heated to 80°C, stopped stirring after 18 hours of reaction, added 2mol / L dilute hydrochloric acid (10ml) to the eggplant-shaped bottle after cooling to room temperature to acidify, extracted with ethyl acetate (50ml×3), combined the organic phases, First wash with a saturated aqueous solution of sodium thiosulfate (10ml), then wash with saturated brine (10ml), dry over anhydrous magnesium sulfate, filter, and the filtrate is evaporated to dryness with a rotary evaporator, and the residue is subjected to flash column chromatography (eluent Purified by ethyl acetate / petroleum ether=1:4, volume ratio) to obtain 0.322g of 2,3-dimethoxybenzaldehyde (yellow solid, yield 85%).

[0022] R f =0.58 (petroleum ether / ethyl acetate=1:3), mp106-108°C.

[0023] 1 H NMR(400MHz,DMSO-d6)δ10.22(s,1...

Embodiment 2

[0025] Add acetonitrile (40ml), aluminum chloride (0.752g, 5.64mmol, 1.1eq), NaI (2.305g, 15.38mmol, 3.0eq) and o-vanillin (0.780g, 5.13mmol) to a 100ml eggplant-shaped flask ), heated to 80°C, stopped stirring after 18 hours of reaction, added 2mol / L dilute hydrochloric acid (10ml) to the eggplant-shaped bottle after cooling to room temperature to acidify, extracted with ethyl acetate (50ml×3), combined the organic phases, First wash with a saturated aqueous solution of sodium thiosulfate (10ml), then wash with saturated brine (10ml), dry over anhydrous magnesium sulfate, filter, and the filtrate is evaporated to dryness with a rotary evaporator, and the residue is subjected to flash column chromatography (eluent Ethyl acetate / petroleum ether=1:4, volume ratio) was purified to obtain 0.620 g of 2,3-dimethoxybenzaldehyde (yellow solid, yield 87%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com