A2 grade fireproof copper composite board and production method thereof

A production method and technology of composite boards, which are applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of low peel strength between core material and aluminum alloy, short service life, poor fireproof performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

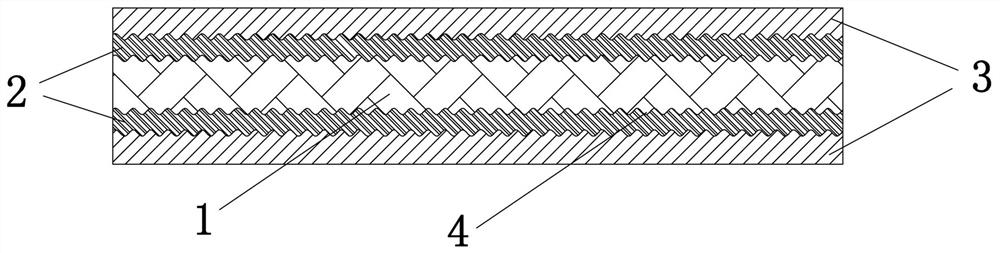

[0017] Such as figure 1 As shown, a class A2 fireproof copper composite board provided in this embodiment includes a core material 1, the surface of the core material 1 is bonded with a copper plate 3 through a polymer film 2, and the bonding surface of the core material 1 and the copper plate 3 is It is a corrugated surface 44, and the core material 1 includes 80 parts of calcium carbonate, 100 parts of magnesium hydroxide, 70 parts of silicon powder, 50 parts of high alumina bauxite, 15 parts of graphene, 10 parts of perlite, 50 parts of oxidized Titanium, 20 parts of barite powder, 5 parts of polypropylene staple fiber, 1 part of glass fiber, 50 parts of silicon carbide, 60 parts of aluminum hydroxide, 10 parts of zinc molybdate, 130 parts of acrylic latex, and 10 parts of high temperature resistant powder. The high-temperature powder includes 50 parts of alumina, 20 parts of boron nitride, 1 part of rare earth lanthanum, 15 parts of zirconium silicide and 5 parts of graphi...

Embodiment 2

[0028] A class A2 fireproof copper composite board provided by this embodiment has the same general structure as that of Embodiment 1, and its main difference is that the core material 1 includes 95 parts by weight of calcium carbonate, 120 parts of magnesium hydroxide, 80 parts of Silicon powder, 60 parts of high alumina bauxite, 20 parts of graphene, 15 parts of perlite, 60 parts of titanium oxide, 30 parts of barite powder, 15 parts of polypropylene staple fiber, 2 parts of glass fiber, 65 parts of silicon carbide, 80 parts of hydrogen Aluminum oxide, 20 parts of zinc molybdate, 145 parts of acrylic latex, 15 parts of high temperature resistant powder.

[0029] The fireproof copper composite board prepared in the above embodiment was tested, and its thermal conductivity was 0.31W / m.K, the peel strength was 10N / mm, and the tensile strength was 55Mpa. The fire performance is determined according to GB 8624-2006, and its combustion performance reaches A2 level, specifically, t...

Embodiment 3

[0032] A class A2 fireproof copper composite board provided by this embodiment has the same general structure as that of Embodiment 1, and its main difference is that the polymer film 2 includes 95 parts by weight of EVA, 30 parts of PMMA, and 5 parts of flame-retardant Agent, 5 parts of titanium dioxide, 10 parts of tackifier, 2 parts of antioxidant, 8 parts of hydrogenated rosin resin.

[0033]The fireproof copper composite board prepared in the above embodiment was tested, and its thermal conductivity was 0.31W / m.K, the peel strength was 10N / mm, and the tensile strength was 55Mpa. The fire performance is determined according to GB 8624-2006, and its combustion performance reaches A2 level, specifically, the combustion growth rate index is 10W / s, the total heat release within 600s is 1.2MJ, and the total smoke production within 600s is 22m 2 , No burning drips within 600s.

[0034] At the same time, the anti-fouling coating of the fireproof copper composite board has a foul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com