Preparation method for wet oxidation catalyst

A wet oxidation and catalyst technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, catalyst protection, etc., to achieve the effects of tight combination, high crushing strength, and improved performance and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

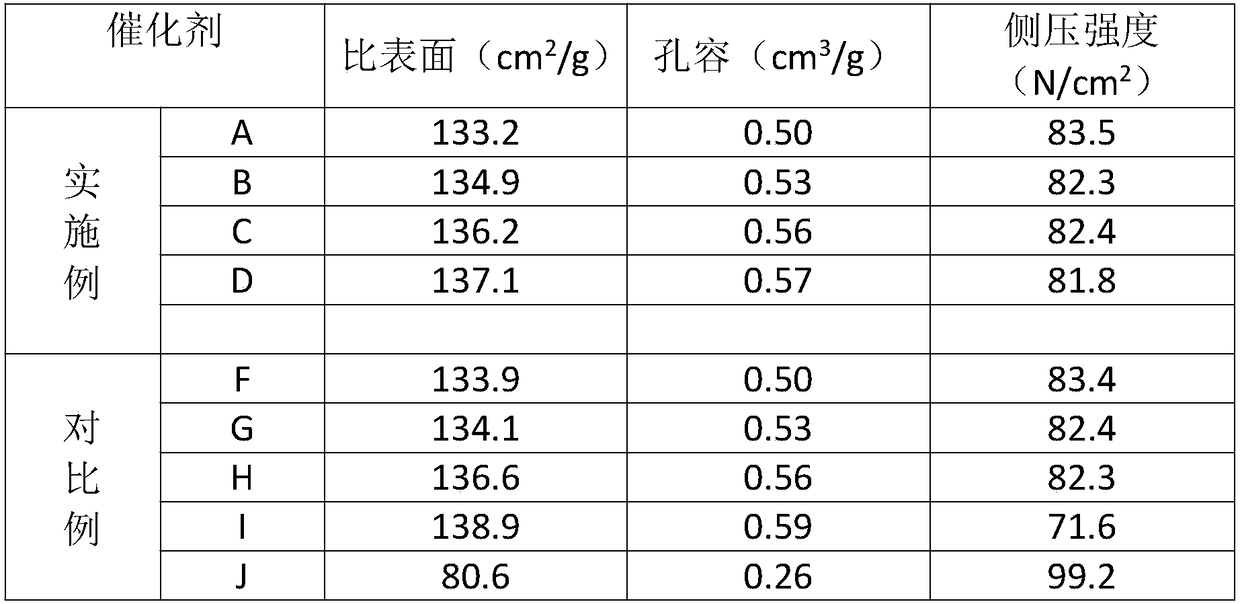

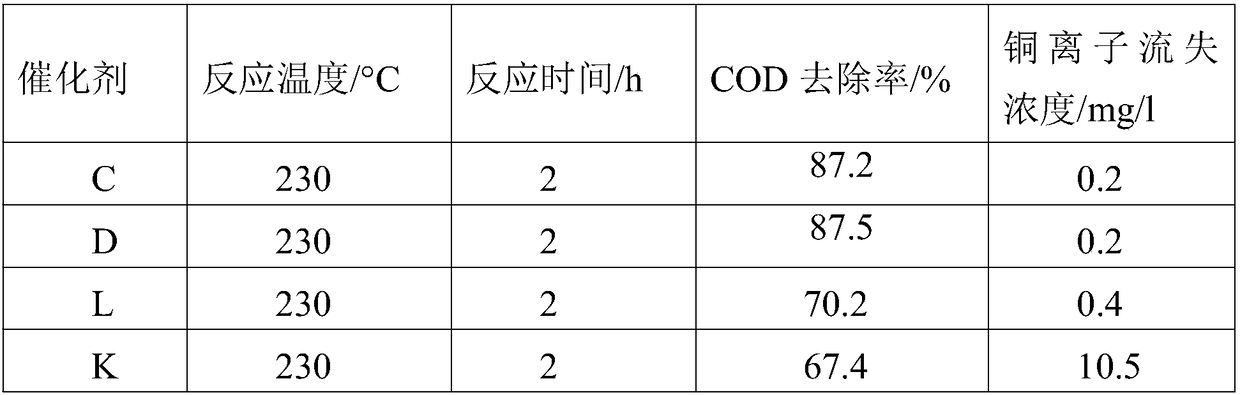

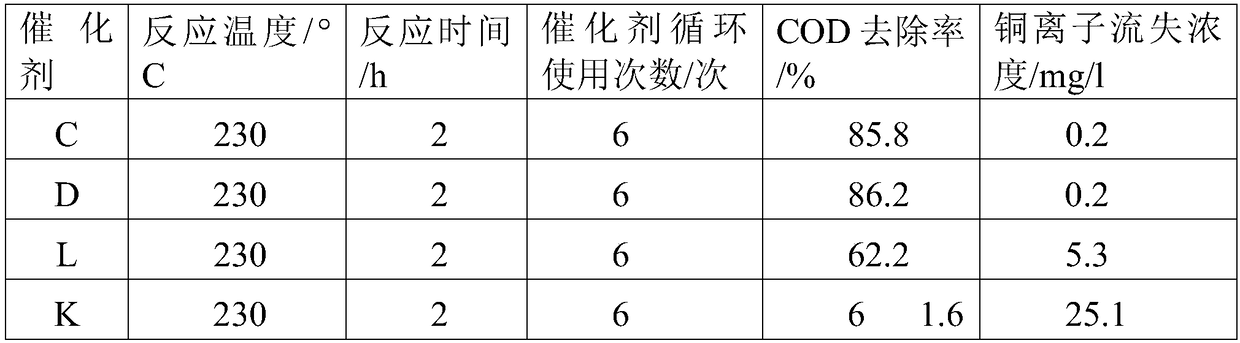

Examples

Embodiment 1

[0038] Impregnate 20g of activated carbon with 7% fructose and beat to form a slurry with a carbon content of 300g / L, add copper nitrate solution containing 20g of CuO, and gradually add ammonia water to adjust the pH value to 8.0 after ultrasonic vibration for 2 hours. After the precipitation is complete, filter , washing; then the washed material is made into a slurry with a water content of 50% with deionized water, and 8g of cerium nitrate solution is added as CeO, and ultrasonic vibration is performed for 1.5h while stirring, and after direct drying, in an inert gas environment Roast at 600°C for 2 hours; after calcination, the powder is mixed with 10g of manganese nitrate solution (calculated as MnO) to make a slurry with a water content of 30%, after stirring, add 1g of turnip powder, stir for 40min, seal and let stand for 24h, and extrude into a clover shape , coated with 6g nanoscale ZrO after drying 2 , after drying, it was calcined at 650° C. for 7 hours in an inert...

Embodiment 2

[0042] Impregnate 30g of activated carbon with 10% fructose and beat to form a slurry with a carbon content of 100g / L, add copper nitrate solution containing 40g of CuO, ultrasonically oscillate for 2 hours, then gradually add ammonia water to adjust the pH value to 8.0, after the precipitation is complete, filter , washing; then the washed material is made into a slurry with a water content of 50% with deionized water, and cerium nitrate solution of 7g in CeO is added, and ultrasonic vibration is performed for 1.5h while stirring, and after direct drying, in an inert gas environment Roast at 500°C for 3 hours; after calcination, the powder is mixed with 25g of manganese nitrate solution (calculated as MnO) to make a slurry with a water content of 30%, after stirring, add 1g of turnip powder, stir for 40min, seal and stand for 24h, and extrude into a clover shape , coated with 8g nanoscale ZrO after drying 2 , after drying, it was calcined at 550° C. for 5 h in an inert gas en...

Embodiment 3

[0046] Impregnate 30g of activated carbon with 15% glucose and beat to form a slurry with a carbon content of 200g / L, add copper nitrate solution containing 40g of CuO, and gradually add ammonia water to adjust the pH value to 9.0 after ultrasonic vibration for 2 hours. After the precipitation is complete, filter , washing; then the washed material is made into a slurry with a water content of 50% with deionized water, and 5g of cerium nitrate solution is added as CeO, and ultrasonic vibration is performed for 1.5h while stirring, and after direct drying, in an inert gas environment Roast at 550°C for 3 hours; after calcination, the powder is mixed with 15g of manganese nitrate solution (calculated as MnO) to make a slurry with a water content of 30%, after stirring, add 1g of urea, stir for 40min, seal and stand for 24h, extrude into a clover shape, bake After drying, apply 5g nanoscale ZrO 2 , after drying, it was calcined at 550° C. for 5 h in an inert gas environment to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com