Fertilizer special for peanut and preparation method thereof

A special fertilizer and peanut technology, which is applied in the field of compound fertilizer, can solve the problems of insignificant yield increase, inability to improve soil structure, and unfulfilling crop fruits, etc., and achieve the goal of promoting rapid and healthy growth, good slow-release effect, and promoting pruning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] An exemplary preparation method includes: adding 10% NaOH solution to the lignosulfonate solution, adjusting the pH of the solution, adding epichlorohydrin (ECH), and performing a synthesis reaction at 60-80°C. After the reaction is finished, take out the reaction product and distill under reduced pressure to remove unreacted epichlorohydrin (ECH), wash the precipitate with deionized water until it is neutral, and dry it in vacuum to obtain the product.

[0068] Preferably, the trace element compound includes but not limited to one or more of sulfates of iron, zinc, manganese, molybdenum, copper, magnesium, titanium or potassium;

[0069] The surfactant is preferably a quaternary ammonium salt cationic surfactant, including but not limited to alkyl trimethyl ammonium salt type, dialkyl dimethyl ammonium salt type, alkyl dimethyl benzyl ammonium salt type, pyridinium salt type , alkylisoquinolinium salt type or benzyl ammonium chloride salt type, preferably alkyltrimethy...

Embodiment 1

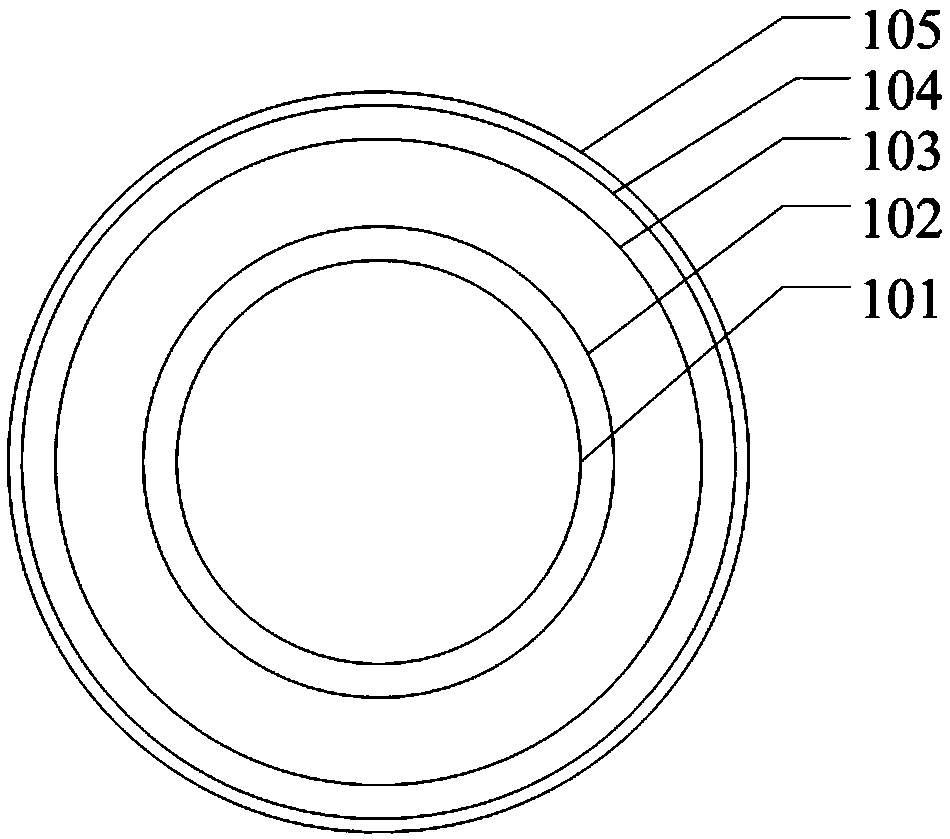

[0115] A special fertilizer for peanuts, comprising a first fertilizer core wrapped in layers, a first coating layer, a second fertilizer layer, a yogurt powder layer and a second coating layer from the inside to the outside; the first fertilizer core includes a ratio of parts by weight Be urea, diammonium phosphate, ammonium chloride and ammonium bicarbonate of 8:3:4:1; The first coating layer comprises the acylated β-cyclodextrin and konjac flour that the weight and number ratio is 0.1:5; The second fertilizer layer includes urea, diammonium phosphate, lime nitrogen, ammonium bicarbonate, humic acid and additives with a ratio of parts by weight of 10:4:4:1:0.1:1; the ratio of parts by weight of additives is 1:1 : 1:1 seaweed powder, loose earth essence, amino acid calcium and dicyandiamide; the second coating layer includes lignin gel, inulin, Urea, oxalic acid, trace element compounds and lauryltrimethylammonium chloride. The weight ratio of the first fertilizer core, the ...

Embodiment 2

[0124] A special fertilizer for peanuts, comprising a first fertilizer core wrapped in layers, a first coating layer, a second fertilizer layer, a yogurt powder layer and a second coating layer from the inside to the outside; the first fertilizer core includes a ratio of parts by weight Be urea, diammonium phosphate, ammonium chloride and ammonium bicarbonate of 10:4:5:1; The first coating layer comprises acylated β-cyclodextrin and konjac flour that the weight and number ratio is 0.5:10; The second fertilizer layer includes urea, diammonium phosphate, lime nitrogen, ammonium bicarbonate, humic acid and additives with a ratio of parts by weight of 15:5:5:2:0.2:1; the ratio of parts by weight of additives is 2:2 : 2:1 seaweed powder, loose earth essence, amino acid calcium and dicyandiamide; the second coating layer includes lignin gel, inulin, Urea, oxalic acid, trace element compounds and lauryltrimethylammonium chloride. The weight ratio of the first fertilizer core, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com