A kind of bacillus subtilis and its application, a kind of enzyme preparation

A technology of Bacillus subtilis and enzyme preparation, applied in the application, enzyme, bacteria and other directions, to achieve the effect of shortening the process flow, stable production quality and good biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

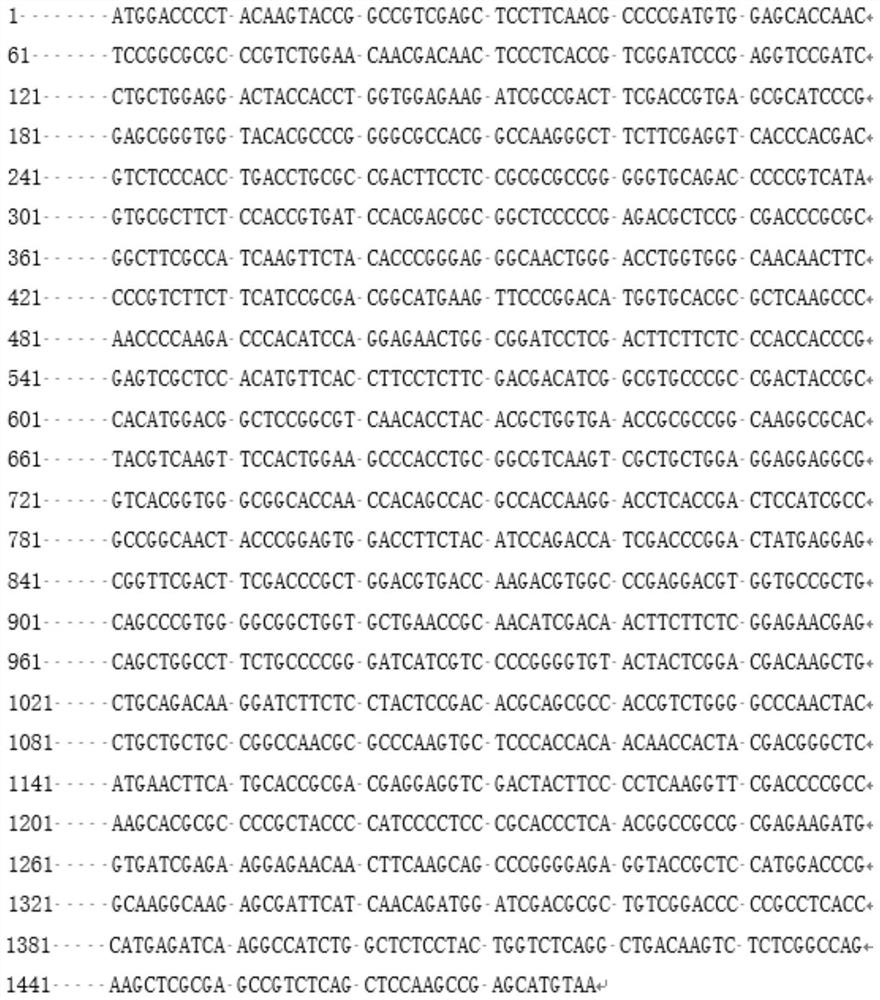

[0033] 1. Acquisition and identification of strain HU528

[0034] Soil was collected from a traditional Tibetan ghee workshop, 10g of protein-rich soil sample was added to 100mL of sterile water, shaken at 28°C for 30min to prepare a bacterial suspension, and the bacterial suspension was diluted and spread on a plate at 28°C Culture on solid medium (0.4% (w / w, the same below) beef extract, 0.6% tryptone, 0.2% yeast extract, 0.5% NaCl, 2% agar, adjust pH 7.0) for 1-2d. Inoculate single colonies with different growth traits obtained on the plate into LB medium (1% tryptone, 0.5% yeast extract, 1% NaCl, adjust pH 7.0) and cultivate for 48 hours, measure the protease activity in the fermentation broth, and obtain protease-producing strains , named strain HU528.

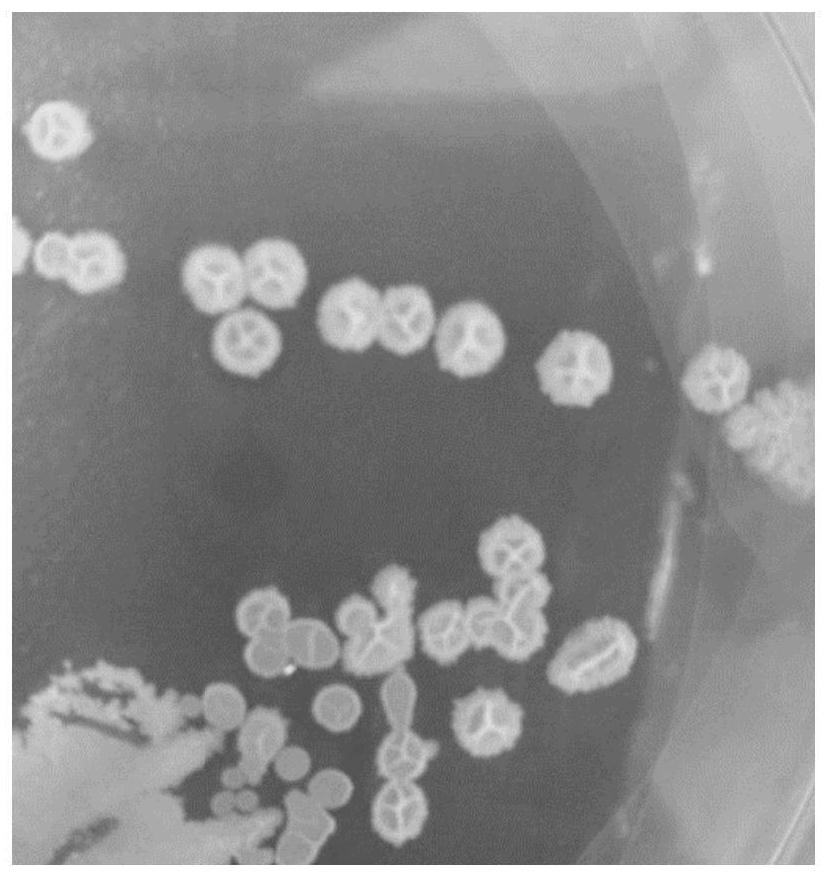

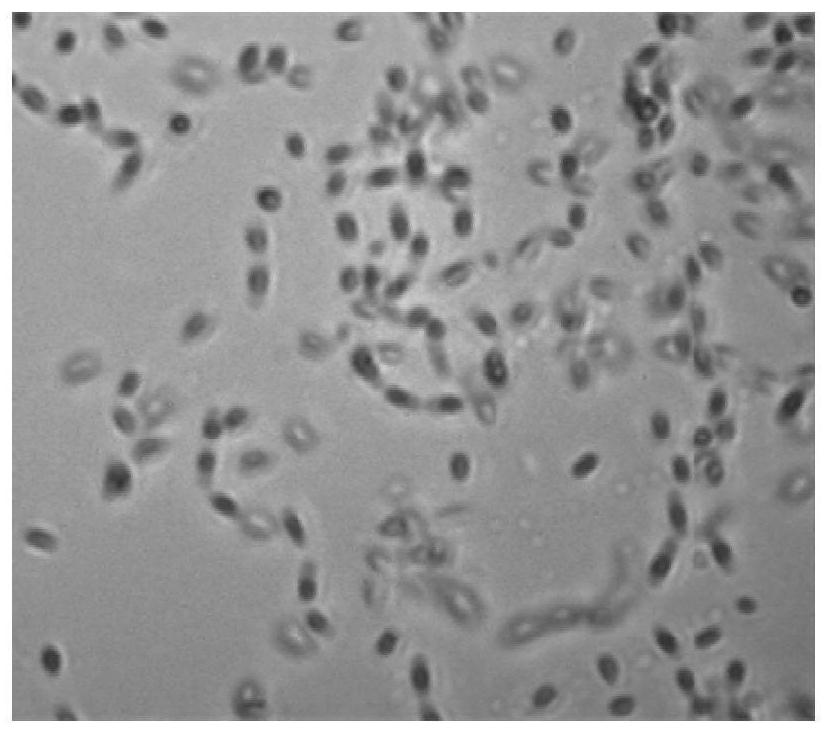

[0035] After the HU528 strain was streak cultured on a solid plate medium at 37°C for 24 hours, the colony was white and round, with rough and wrinkled surfaces and irregular edges ( figure 1 ). Microscopic observation...

Embodiment 2

[0053] Prepare the liquid medium as follows: add tryptone 2% (w / w, the same below), glucose 0.1%, CaCl in distilled water 2 0.2%, NaCl 0.1%, after mixing evenly, adjust the pH of the liquid medium to 5.0. After sterilizing at 121° C. for 20 minutes, the primary seeds of Bacillus subtilis HU528 were inoculated in the liquid medium at 1.0% (v / v), and the temperature was 30° C., and the stirring speed was 150 r / min. After fermentation and cultivation for 45 hours, The obtained fermentation liquid was centrifuged at 4° C. and 8000 r / m for 10 minutes to remove bacteria, and the fermentation supernatant was the enzyme preparation. The protease activity in the enzyme preparation was 800U / mL, and the β-glucanase activity was 2.0U / mL.

[0054] Add the above-mentioned enzyme preparation containing 2000U of protease activity (2.5mL enzyme preparation / g dry yeast) to the edible yeast powder by every gram of yeast powder, supplement sterile water to the volume ratio of edible yeast powder...

Embodiment 3

[0059] Prepare the liquid medium as follows: add tryptone 1.5% (w / w, the same below), glucose 0.8%, CaCl in distilled water 2 0.05%, NaCl 0.15%, after mixing evenly, adjust the pH of the liquid medium to 6.0. After sterilizing at 121°C for 20 minutes, inoculate the primary seeds of Bacillus subtilis HU528 in liquid medium at 1.0% (v / v), ferment and cultivate for 60 hours at a temperature of 25°C and a stirring speed of 180r / min. , the obtained fermentation broth was centrifuged at 4°C and 8000r / m for 10min to remove bacteria, and the fermentation supernatant was the enzyme preparation. The protease activity in the enzyme preparation was 1600U / mL, and the β-glucanase activity was 3.0U / mL.

[0060] Add the above-mentioned enzyme preparation containing 9600U of protease activity (6mL enzyme preparation / g dry yeast) to the edible yeast powder per gram of yeast powder, and add sterile water to the volume ratio of the edible yeast powder to the mixed liquid (solid-liquid ratio, w / v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com