Thiosulfate silvering additive, preparation method thereof and electroplate liquid containing same

A technology of thiosulfate and additives, which is applied in the field of silver plating, can solve the problems of great health damage to operators, unfavorable environmental protection of sewage, and uneven silver plating layer, etc., to achieve improved flatness, low brittleness, and good discoloration resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

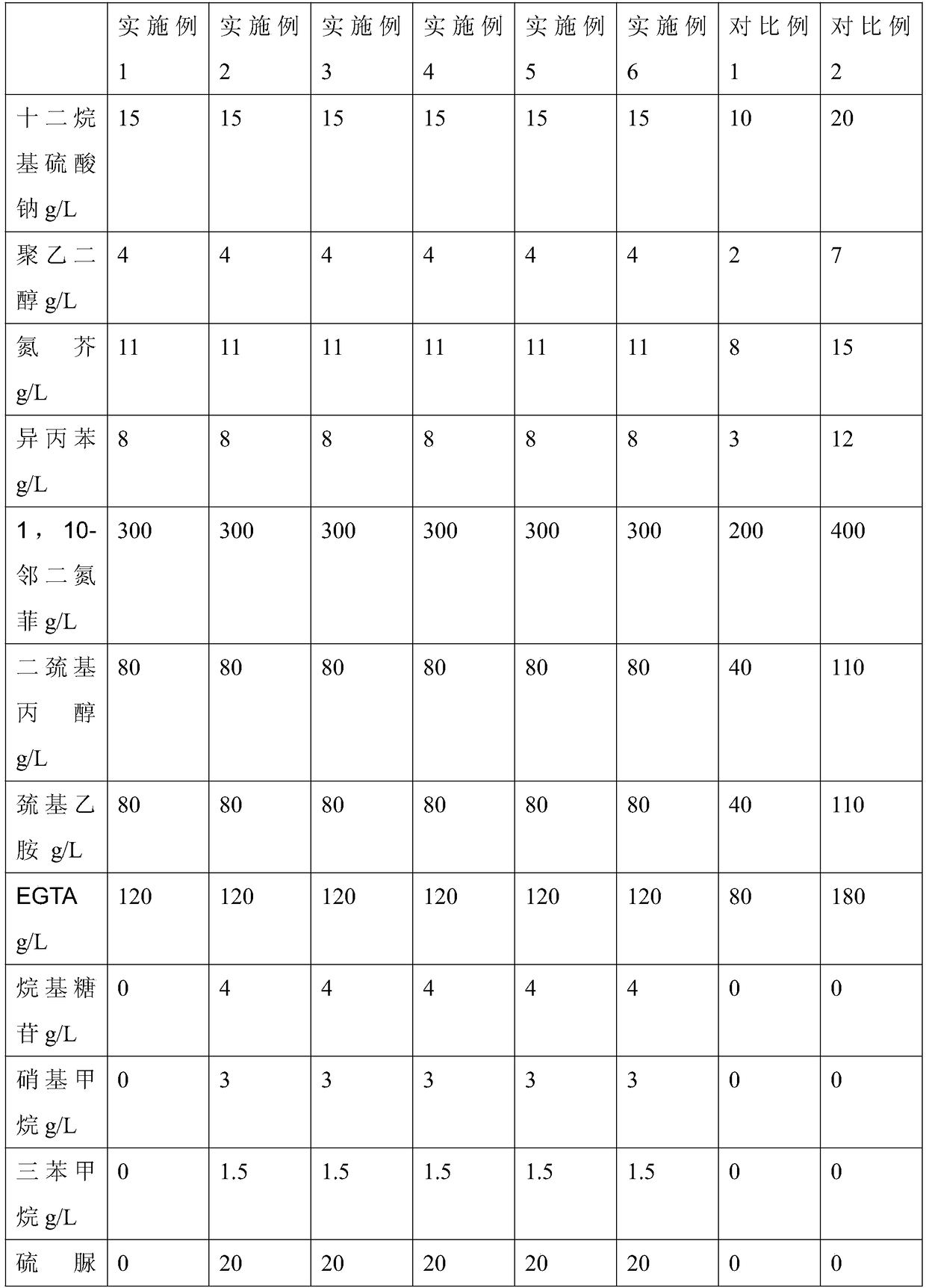

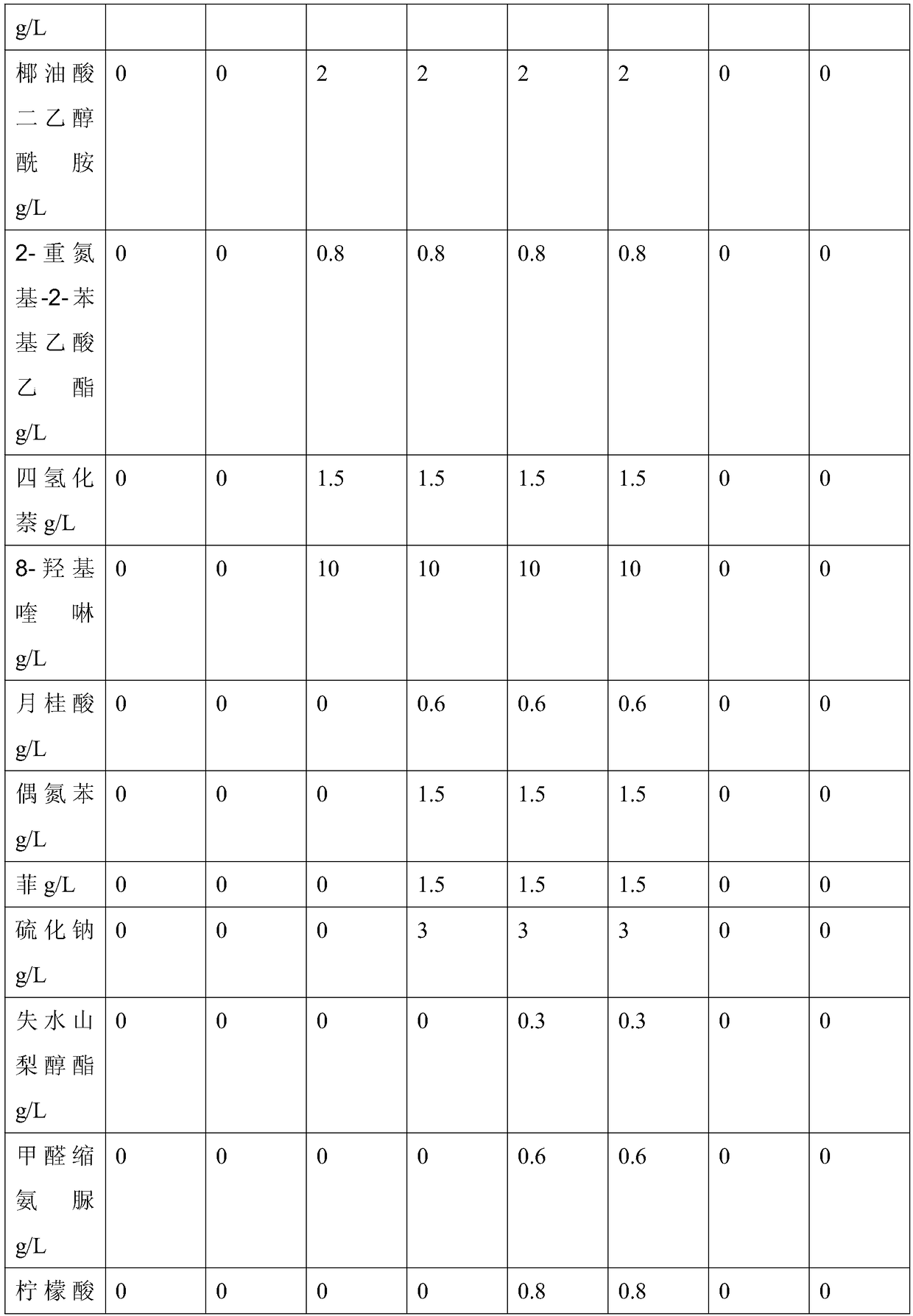

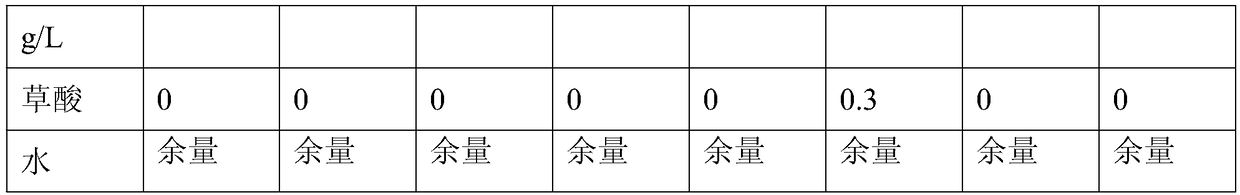

Examples

preparation example Construction

[0039] The preparation method of the thiosulfate silver plating additive of above-mentioned each example, comprises the steps:

[0040] 1) Heat the water to 70-80°C, and add sodium lauryl sulfate, polyethylene glycol, alkyl glucoside, cocoic acid diethanolamide, lauric acid and sorrel in sequence under stirring at 1300r / min After alcohol ester, continue stirring at 70-80°C, 1200-1400r / min for 12min;

[0041] 2) 1,10-phenanthroline, dimercaptopropanol, mercaptoethylamine, ethylene glycol bis(2-aminoethyl ether)tetraacetic acid, thiourea, 8-hydroxyquinoline, sodium sulfide, citric acid and oxalic acid were sequentially added to the material obtained in step 1), and then stirred at 70-80°C and 1300r / min for 18min;

[0042] 3) Nitrogen mustard, nitromethane, phenyldiazoic acid, azobenzene, formaldehyde semicarbazone, cumene, triphenylmethane, tetralin and phenanthrene are added in the material obtained in step 2) successively, and then Stir at 70-80°C and 1300r / min for 25min to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com