Chinese chestnut health-care instant beverage prepared by freeze concentration drying method and method thereof

A technology of freeze concentration and drying, which is applied in food drying, food freezing, and food ingredients as antimicrobial preservation, etc., to achieve the effects of improving acidic constitution, reasonable process design, and activating hormones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

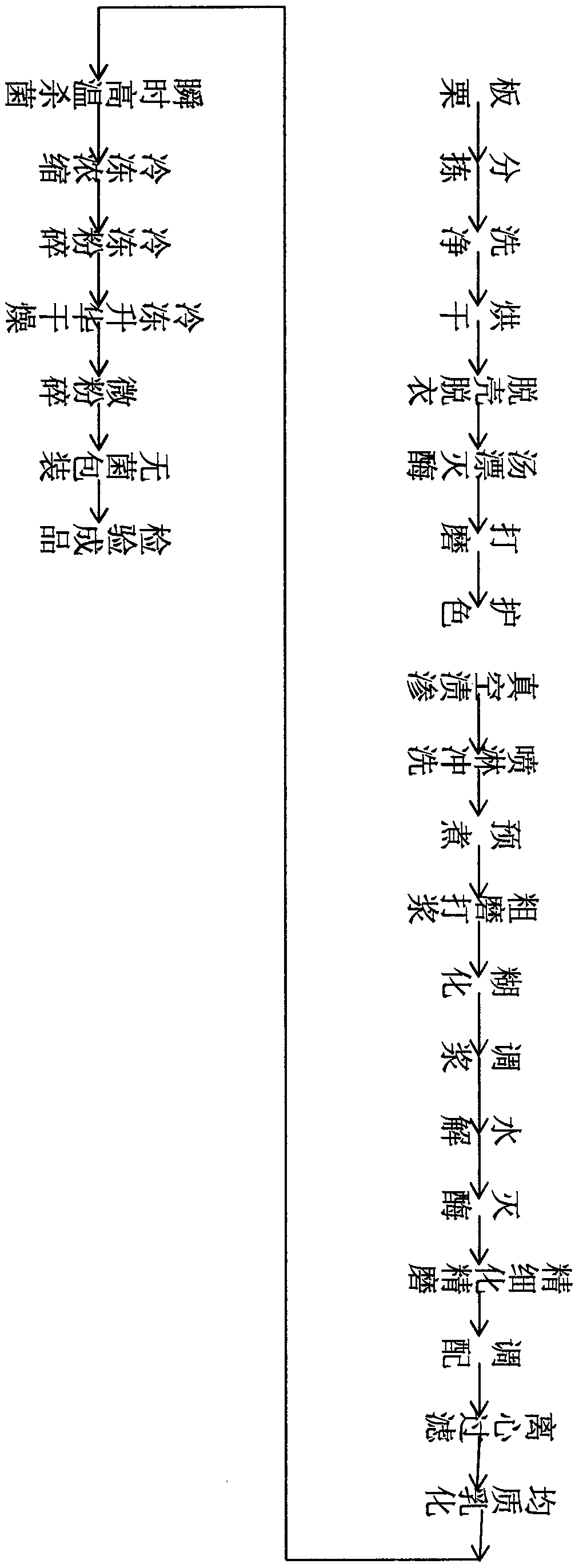

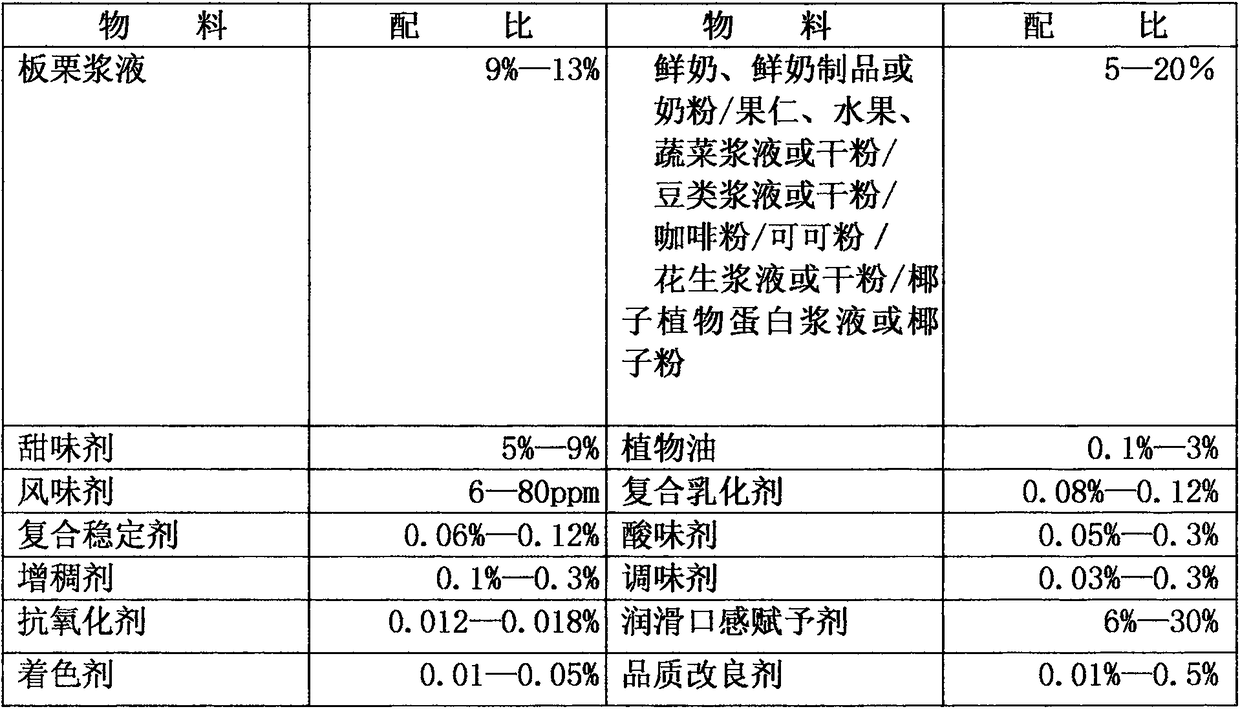

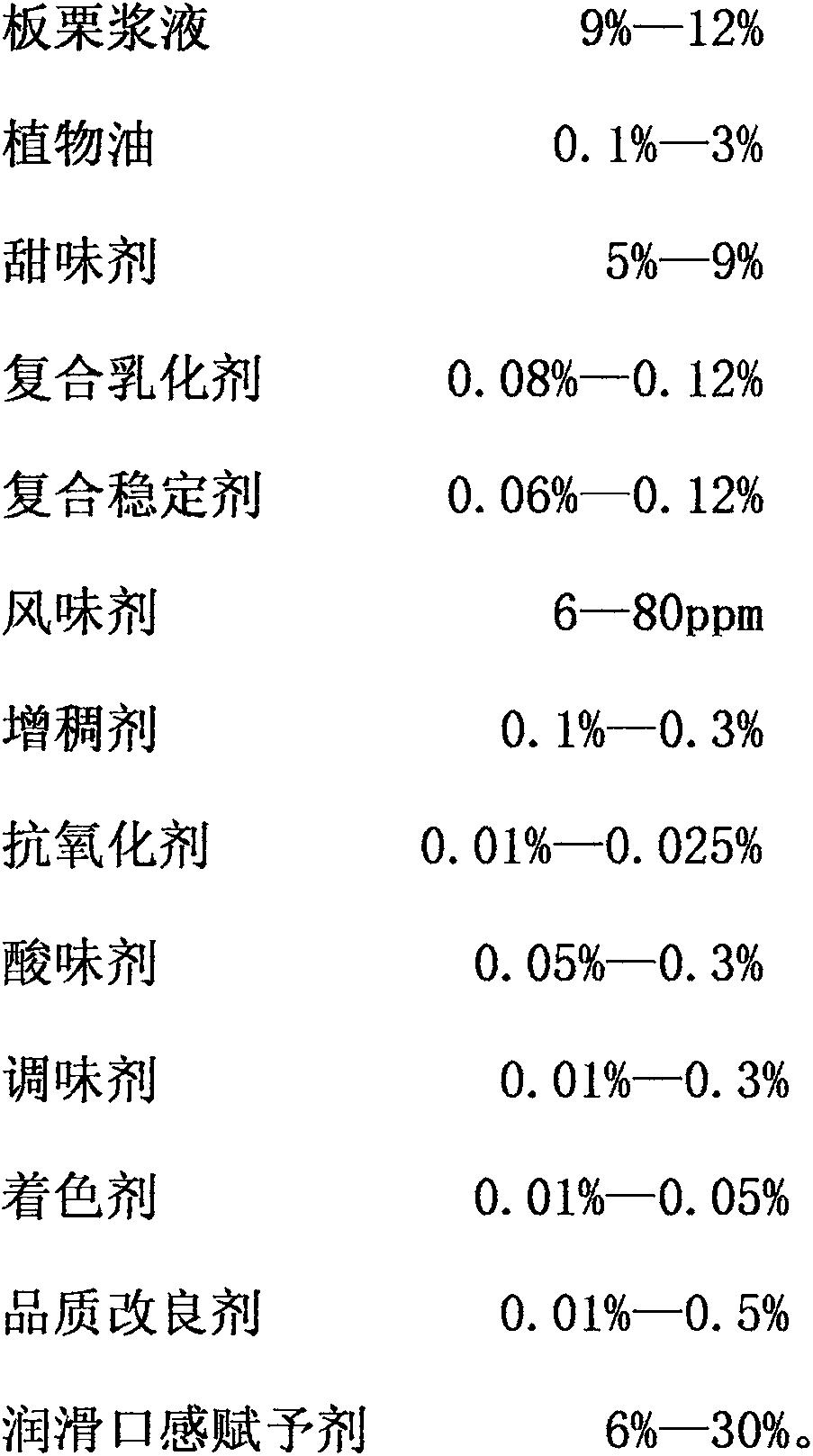

Method used

Image

Examples

example 1

[0090] The preparation method of the present invention is as follows: 1. Sorting the chestnut as the main raw material, soaking the fruit with clear water or low-concentration salt water for about 70 seconds, then picking up the floating or semi-floating fruit particles due to the low density, and selecting the fully submerged Fruits at the bottom of the water; washing; drying: that is, on the dryer, which supplies clean hot air at 55°C, and takes 30 minutes; shelling and undressing.

[0091] 2. Get 10.5Kg of chestnut kernels and put the chestnut kernels that have been shelled and uncoated into 0.25% citric acid and blanched in hot water at 70°C for 20 minutes to kill oxidase or peroxidase.

[0092] 3. Grind the skin of the chestnut kernels, remove 0.1mm of the skin of the chestnut kernels, spray and rinse, and then use vacuum impregnation technology for deep color protection under sealed conditions, temperature: 80°C, pressure: 0.39Mpa , Vacuum degree: 650-720mmHg; put into t...

example 2

[0110] The preparation method of the present invention is as follows: 1. Sorting the chestnut as the main raw material, soaking the fruit with clear water or low-concentration salt water for about 75 seconds, then picking up the floating or semi-floating fruit particles due to the low density, and selecting the fully submerged Fruits on the bottom of the water; washing; drying: that is, on the dryer, which supplies clean hot air at 55°C and takes 25 minutes; shelling and undressing.

[0111] 2. Take 10.5Kg of shelled and uncoated chestnut kernels, put them into hot air and steam at 145°C for blanching for 5 minutes, to kill oxidase or peroxidase.

[0112] 3. Grind the skin of the chestnut kernels, remove 0.1mm of the skin of the chestnut kernels, spray and rinse, and then use vacuum impregnation technology for deep color protection under sealed conditions, temperature: 80°C, pressure: 0.39Mpa , Vacuum degree: 650-720mmHg; put into the color protection solution for color protec...

example 3

[0128] The processing technology process of present example is: put the chestnut kernel of shelling off coat and put into containing 0.25% citric acid, blanching 15 minutes in the hot water of 75 ℃, to kill oxidase or peroxidase. Use barley malt powder as the enzyme source to hydrolyze chestnut slurry: select the activity value of α-amylase activity to reach 3.96U / g malt or more, β-amylase activity to reach 4.853U / g malt or more, and protease activity to reach 278.70u / g Above the malt, add 28% barley malt powder to the amount of chestnut raw materials, hydrolyze at 70°C for 25 minutes, the hydrolysis pH value is 5.5, add 15% fresh milk after inactivating the enzyme, mix and put it into a colloid mill for fine grinding. Adopt the traditional homogenizer method, and increase the homogenization pressure according to the principle of improving the homogenization effect, the first-stage valve pressure is 23MPa, and the second-stage valve pressure is 54MPa; increase the homogenizatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vitality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com