Method for preparing renewable magnesium-based bone material with Mg/TiO2-HA gradient porous coating

A gradient porous and coating technology, applied in the field of medical materials, can solve the problems of high residual stress, high price, and difficult coating at the interface between the substrate and the coating, so as to reduce or eliminate the stress shielding phenomenon, improve the bonding strength, and maintain good biological properties. active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

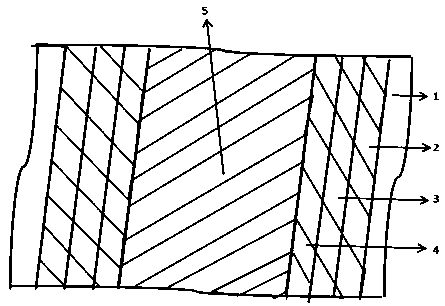

[0024] 1. Laser cladding raw material ratio: sintering is divided into two groups, the first group uses Mg particles (99.3% purity) and Ag powder with a molar ratio of 48:2 mixed powder, the second group uses Mg, TiO2, HA three According to its gradient, it is divided into four kinds of ratios: high-purity HA, 70%HA+20%TiO2+10%Mg, 5%HA+30%TiO2+35%Mg, 10%HA+20%TiO2+70%Mg mixed powder. The above-mentioned materials were dried at 140° C. for 10 hours in a drying oven respectively, and refined crystal grains were obtained by mechanical ball milling. After the powders were mixed evenly, they were dried at 80° C. for 1 hour to obtain mixed nanopowders;

[0025] 2. 3D printing model construction: Through CAD modeling, generate a 3D bracket (20mm long, 20mm in diameter), and generate a model of a hole with a porosity of 50%~80% and a pore diameter of 100-600μm at the same time, and control the thickness of the coating at About 0.4mm. Then the CAD model is layered by computer to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com