Making method of special food suitable for intestinal tracts of patients at perioperative period of esophagus cancer

A perioperative and esophageal cancer technology, which is applied in the field of food preparation for perioperative patients with esophageal cancer, can solve the problems of high temperature resistance, pH sensitivity of sample loading, lack of mechanical properties, poor slow-release effect, and easy-to-use products. Damage and other problems, to achieve the effect of improving product efficacy, enhancing the body's immune stress ability, and enhancing immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

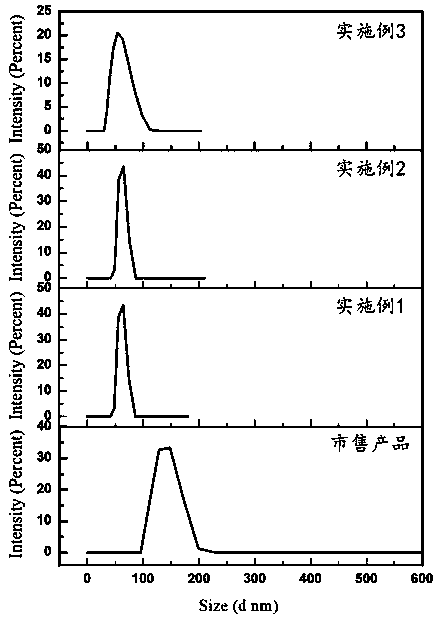

Embodiment 1

[0064] A method for preparing special food suitable for perioperative patients with esophageal cancer, comprising the following steps:

[0065] (1) Take shiitake mushrooms, white fungus, winter worms, and summer grass (mass ratio is 2:3:1:1.5) and clean them, control the water, crush and beat (the solid-liquid ratio is 1:6 when beating, and the solid is controlled Dried shiitake mushrooms, white fungus, winter worms, summer grass, the liquid is pure water), and the beating liquid is sterilized at 70°C for 30 minutes in a sterilizing pot;

[0066] Add a compound enzyme composed of cellulase, amylase and pectinase (the mass ratio of cellulase, amylase and pectinase is 2:1:3) to the sterilized beating liquid, and the enzymatic hydrolysis time for 4 hours, and the enzymatic hydrolysis temperature is 30°C.

[0067] After the enzymolysis is completed, pour the feed liquid into a three-legged centrifuge, control the speed at 4000r / min, centrifuge for 30min, and take the supernatant;...

Embodiment 2

[0107] (1) Take shiitake mushrooms, white fungus, winter worms, and summer grass (mass ratio is 3:5:3:3), clean them and control the water, then crush and beat them (the solid-liquid ratio is 1:8 when beating, and the solids are controlled dry). watery mushrooms, white fungus, winter worms, summer grass, the liquid is pure water), and the beating liquid is sterilized at 70°C for 30 minutes in a sterilizing pot;

[0108] Add cellulase, amylase, and pectinase (mass ratio: 4:3:5) to the sterilized beating liquid, control the solid-liquid ratio at 1:10, enzymolysis time is 8 hours, and enzymolysis temperature is 50°C;

[0109] After the enzymatic hydrolysis is completed, pour the feed liquid into a three-legged centrifuge, control the speed at 6000r / min, centrifuge for 20min and take the supernatant;

[0110] (2) freeze-dried powder of bifidobacteria and freeze-dried powder of Lactobacillus (mass ratio of 1:1), functional amino acids (L-glutamine, arginine, aspartic acid, The ma...

Embodiment 3

[0118] (1) Take shiitake mushrooms, white fungus, winter worms, and summer grass (mass ratio 2:3:1:1) and clean them, crush and beat them, control the solid-liquid ratio at 1:8, enzymolysis time is 6 hours, and enzymolysis temperature At 40°C, the beating liquid was sterilized at 70°C for 30 minutes in a sterilizing pot. Add cellulase, amylase and pectinase (mass ratio 3:2:4) to the sterilized beating liquid to carry out compound enzymolysis. After the enzymatic hydrolysis is completed, pour the feed liquid into a three-legged centrifuge, control the speed at 5000r / min, centrifuge for 25min and take the supernatant;

[0119] (2) Bifidobacterium freeze-dried powder and Lactobacillus rhamnosus freeze-dried powder (mass ratio is 1: 2) are mixed with composite bacterial agent freeze-dried powder, functional amino acid (L-glutamine, arginine, lysine acid, aspartic acid, the mass ratio is 2:1:1:2), multivitamins (vitamin B12, vitamin B6, vitamin C, vitamin D, vitamin A, the mass ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com