Silicon-phenyl-terthiophene derivative and preparation method and application thereof

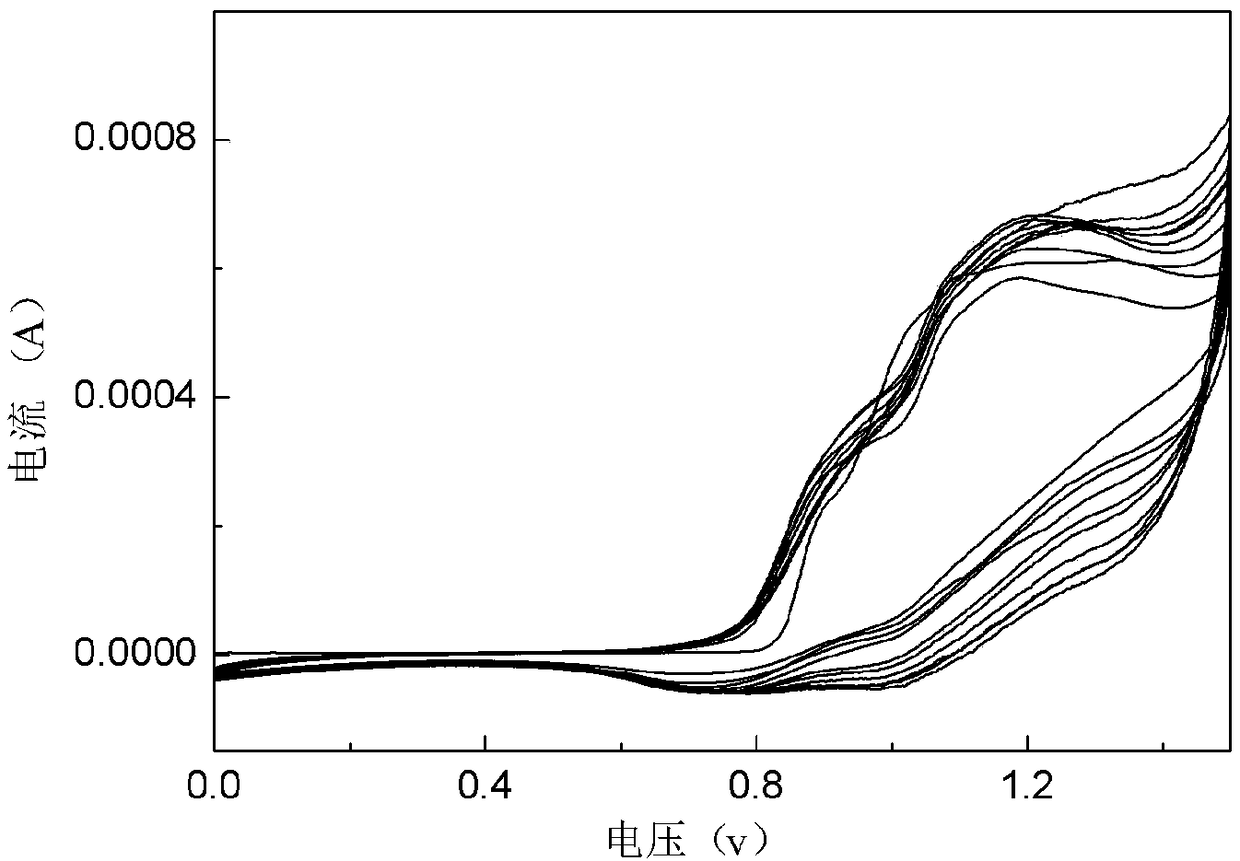

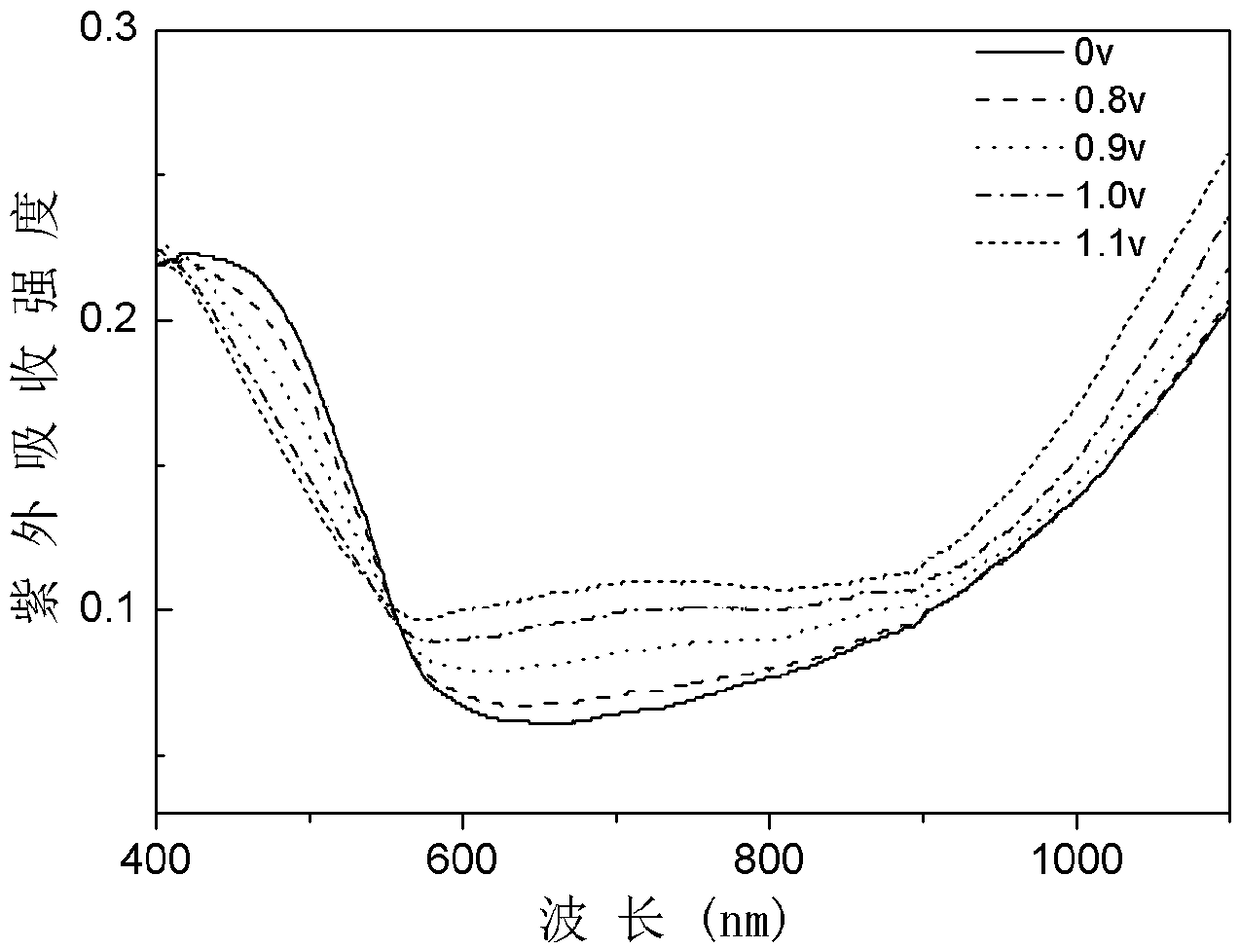

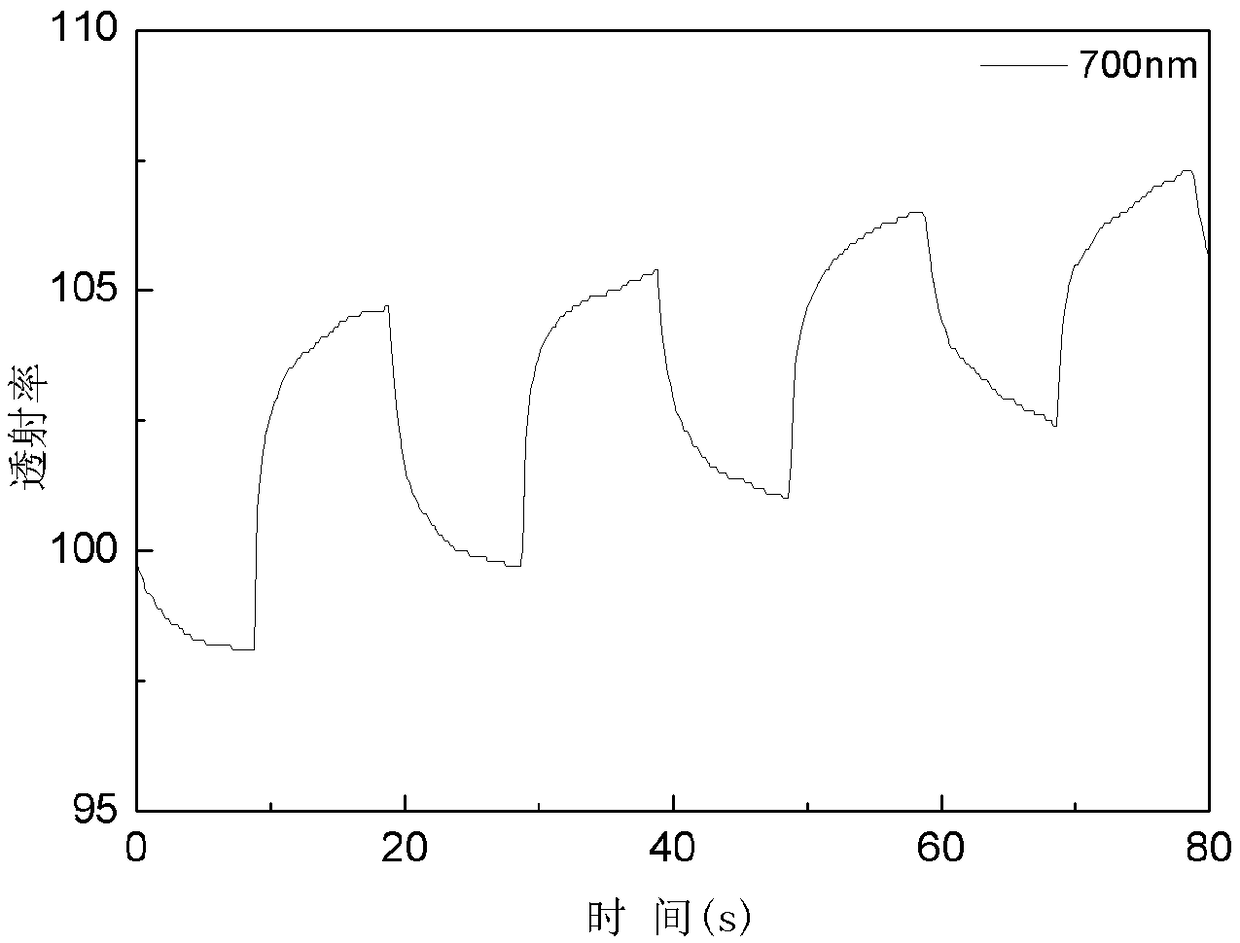

A technology of triple thiophene and derivatives, used in organic silicon compounds, chemical instruments and methods, electrolytic organic production, etc., can solve the problems of poor solubility and large rigidity of the main chain, and achieve good electrochromic performance and good redox ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Specific synthesis of 2-tri(n-butyl)tin terthiophene compound 2,2':5',2"-terthiophene (15mmol, 3.7g) was added to a 250mL conical round-bottomed flask, under nitrogen protection, added without Water anaerobic tetrahydrofuran solution 100mL, stirring 2,2':5',2"-tertiary thiophene fully dissolved, slowly add n-butyllithium cyclohexane solution (15mmol, 2.5mol / L, 6mL), kept stirring at low temperature for two hours, then slowly added tributyltin chloride (20mmol, 1.2g / L, 5.5mL) dropwise, stirred at -78°C for one hour, then returned to room temperature and stirred for 24 hours, the reaction ended Finally, the reactant was concentrated, then chromatographed on a column of aluminum oxide, concentrated, and spin-dried to obtain an anhydrous liquid product, which was directly used in the next reaction without further purification.

Embodiment 2

[0030] Preparation of bis-(4-bromophenyl)-diphenylsilane

[0031] Add 1,4-dibromobenzene (20mmol, 4.7g) into a 250mL conical round-bottom flask, under nitrogen protection, add 100mL of anhydrous and oxygen-free ether solution, stir 1,4-dibromobenzene to fully dissolve, and Slowly add n-butyl lithium cyclohexane solution (21mmol, 8.4mL) dropwise under nitrogen protection at 78°C, keep stirring at low temperature for two hours, then slowly add dichlorodiphenylsilane (10mmol, 2.1mL) dropwise, and then return to Stir at room temperature for 12 hours. The solution was poured into water to quench the reaction, extracted three times with anhydrous ether, and the collected organic phase was dried over anhydrous magnesium sulfate overnight. After filtration, the solution was concentrated, and the crude product was recrystallized from absolute ethanol and dichloromethane to obtain 3.46 g of a white solid, with a yield of 70%. 1 H NMR (400MHz, CDCl 3 )δ7.46-7.44(8H,m,Ar-H),7.40-7.37(2...

Embodiment 3

[0033] Preparation of Silicon-Phenyl-Terthiophene Derivatives

[0034] Bis-(4-bromophenyl)-diphenylsilane (1.48g, 3mmol), and 2-tri(n-butyl)tin terthiophene (6.4g, 12mmol) obtained in Example 1, Pd(PPh 3 ) 4 (24.3mg, 0.021mmol) were added sequentially under a nitrogen atmosphere, 25ml of DMF (N,N-dimethylformamide) was added, the temperature was rapidly raised to 130°C, the system was refluxed for 16h, the reaction was stopped, cooled to room temperature, and respectively used Extract with dichloromethane and water, add anhydrous MgSO to the obtained organic phase After drying, then separate and purify by column chromatography, the stationary phase is 300 mesh silica gel, the mobile phase is dichloromethane / petroleum ether (1:5), and finally orange The solid silicon-phenyl-terthiophene derivative 0.7g, the yield is 50%. MALDI-TOF-MS (M) (m / z): 828.9 [M+H] + . 1 H NMR (400MHz, CDCl 3)δ7.65–7.62(m,12H),7.50–7.46(m,2H),7.44–7.40(m,4H),7.30(d,J=3.8Hz,2H),7.25–7.22(m,2H) , 7.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com