Method for removing sulfur dioxide and recycling sulfur in flue gas

A sulfur dioxide and sulfur recovery technology, applied in chemical instruments and methods, anaerobic digestion treatment, sulfur preparation/purification, etc., can solve the problems of reducing the efficiency of microbial treatment, not enough economical and environmental protection, and high environmental requirements, and improve the treatment of bacteria. Efficiency, reducing the economic burden of enterprises, and alleviating the effect of environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]Embodiment 1: The flue gas of this embodiment adopts that the concentration of sulfur dioxide in the flue gas of a certain coal-fired boiler is 2000mg / Nm 3 ;

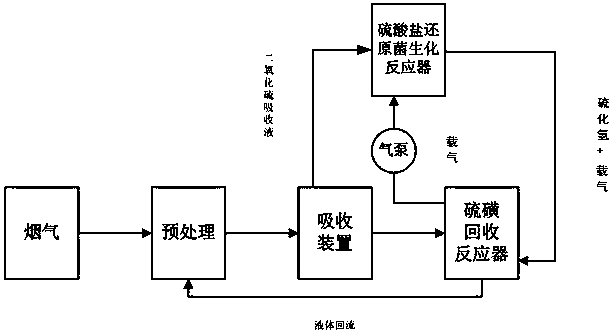

[0029] Such as figure 1 As shown, a method for sulfur dioxide removal and sulfur recovery in flue gas, the specific steps are as follows:

[0030] (1) Pretreatment of dust removal, desalination, and cooling of sulfur dioxide-containing flue gas makes the content of total suspended particulate matter (TSP) in the flue gas less than 10%; pretreatment of desalination and cooling is beneficial to obtain clean sulfur dioxide absorption liquid without additional Dosing of chemicals;

[0031] (2) Pass the flue gas pretreated in step (1) into the absorption device (spray tower) and use water to absorb sulfur dioxide in the flue gas to obtain sulfur dioxide absorption liquid and sulfur removal flue gas;

[0032] (3) introducing 40% of the sulfur dioxide absorbing solution in step (2) into the sulfate microbial reducing...

Embodiment 2

[0035] Embodiment 2: The flue gas of this embodiment adopts the concentration of sulfur dioxide in the flue gas of a certain coal-fired boiler as 3000mg / Nm 3 ;

[0036] Such as figure 1 As shown, a method for sulfur dioxide removal and sulfur recovery in flue gas, the specific steps are as follows:

[0037] (1) Pretreatment of dust removal, desalination, and cooling of sulfur dioxide-containing flue gas makes the content of total suspended particulate matter (TSP) in the flue gas less than 10%; pretreatment of desalination and cooling is beneficial to obtain clean sulfur dioxide absorption liquid without additional Dosing of chemicals;

[0038] (2) Pass the flue gas pretreated in step (1) into the absorption device (sieve plate tower) and use water to absorb sulfur dioxide in the flue gas to obtain sulfur dioxide absorption liquid and sulfur removal flue gas;

[0039] (3) introducing 45% of the sulfur dioxide absorbing solution in step (2) into the sulfate microbial reduci...

Embodiment 3

[0042] Embodiment 3: The flue gas of this embodiment adopts that the concentration of sulfur dioxide in the flue gas of a certain coal-fired boiler is 4000mg / Nm 3 ;

[0043] Such as figure 1 As shown, a method for sulfur dioxide removal and sulfur recovery in flue gas, the specific steps are as follows:

[0044] (1) Pretreatment of dust removal, desalination, and cooling of sulfur dioxide-containing flue gas makes the content of total suspended particulate matter (TSP) in the flue gas less than 10%; pretreatment of desalination and cooling is beneficial to obtain clean sulfur dioxide absorption liquid without additional Dosing of chemicals;

[0045] (2) Pass the flue gas pretreated in step (1) into the absorption device (bubble tower) and use water to absorb sulfur dioxide in the flue gas to obtain sulfur dioxide absorption liquid and sulfur removal flue gas;

[0046] (3) introducing 50% of the sulfur dioxide absorbing solution in step (2) into the sulfate microbial reduci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com