Technology and system for treating petrochemical wastewater

A technology of petrochemical wastewater and treatment process, applied in the field of water treatment, can solve the problems of excessive effluent index, low biodegradability, and unsuitability to industry development requirements, etc., and achieve the ideal effect of removing residual COD content and degreasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

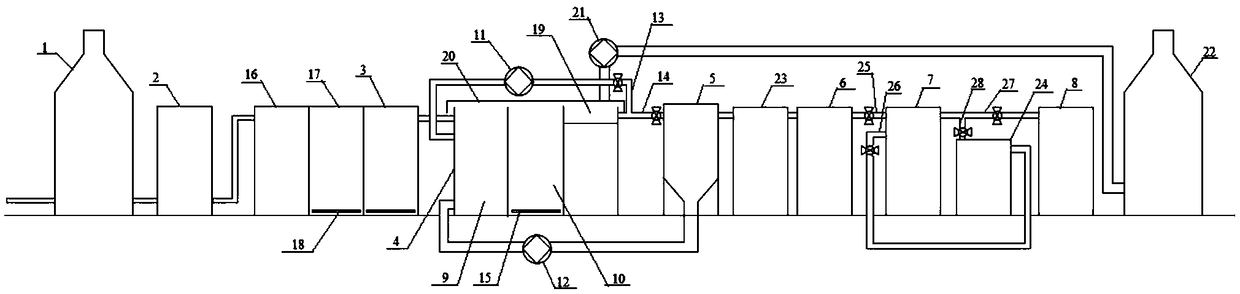

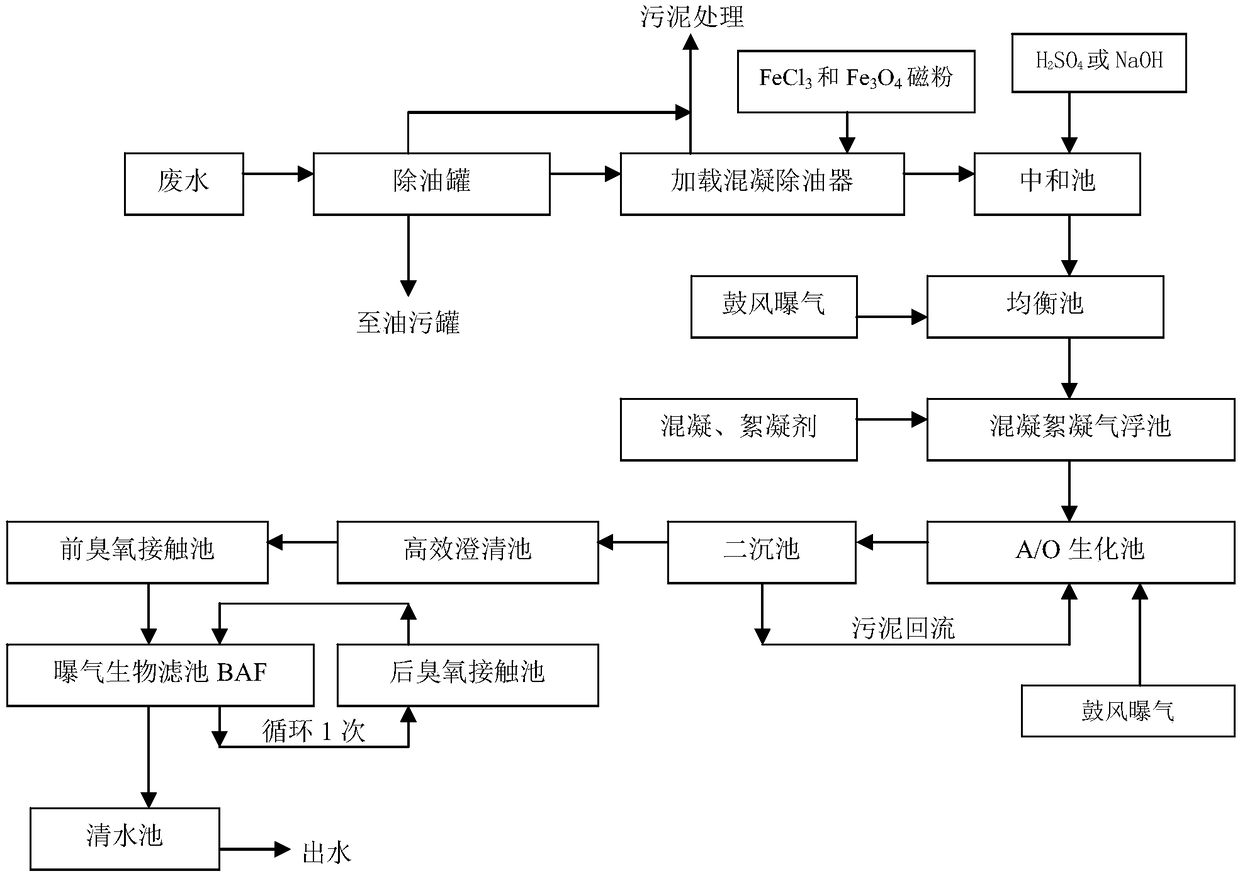

[0049] A petrochemical wastewater treatment process, comprising the following steps:

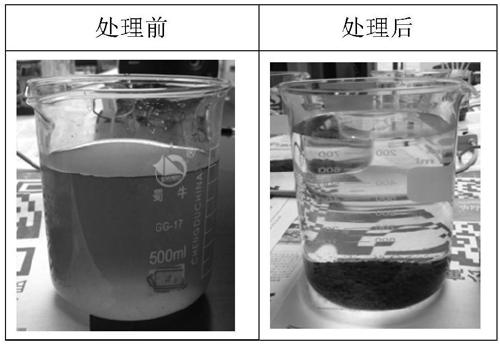

[0050] (1) Primary treatment: the waste water is left to stand for more than 24 hours for preliminary oil removal, and then the loading coagulation method is used to further remove free insoluble oil;

[0051] (2) Secondary treatment: adopt air flotation and chemical treatment to process the oil-water emulsion treated in step (1), remove suspended solids (SS) and the oil separated from the emulsion;

[0052] (3) Biochemical treatment: the effluent of step (2) is treated by anoxic / aerobic (A / O) activated sludge method, which includes anoxic section and aerobic section During treatment, part of the effluent that has been fully reacted in the aerobic section needs to be returned to the anoxic section, mixed with the effluent from step (2) and treated together to remove organic matter and ammonia nitrogen; and the anoxic / aerobic active pollution The wastewater treated by mud method is sedimente...

Embodiment 2

[0055] A petrochemical wastewater treatment process, comprising the following steps:

[0056] (1) Primary treatment: the waste water is left to stand for more than 24 hours for preliminary oil removal, and then the loading coagulation method is used to further remove free insoluble oil, wherein the loading coagulation method is: throwing in the coagulation reaction process Add coagulant FeCl 3 Dosing Fe at the same time 3 o 4 Magnetic powder, Fe 3 o 4 The magnetic powder forms a crystal nucleus to absorb oil, improve the flocculation effect, remove free insoluble oil, and recover Fe through the magnetic separator 3 o 4 magnetic powder;

[0057] (2) Secondary treatment: add coagulant FeCl by air flotation and chemical treatment 3 Process the oil-water emulsion treated in step (1), remove suspended solids (SS) and oil separated from the emulsion;

[0058] (3) Biochemical treatment: the effluent of step (2) is treated by anoxic / aerobic (A / O) activated sludge method, which...

Embodiment 3

[0061] A petrochemical wastewater treatment process, comprising the following steps:

[0062](1) Primary treatment: the waste water is left to stand for more than 24 hours for preliminary oil removal, and then the loading coagulation method is used to further remove free insoluble oil;

[0063] (2) Secondary treatment: use H 2 SO 4 or NaOH to neutralize the pH value of the effluent in step (1) to 7, adjust the water quality and quantity, and then remove the sulfide through aeration and oxidation treatment, and then add coagulant FeCl by air flotation and chemical treatment 3 The oil-water emulsion treated in step (1) is processed to remove suspended solids and oil separated from the emulsion.

[0064] (3) Biochemical treatment: the effluent of step (2) is treated by anoxic / aerobic (A / O) activated sludge method, which includes anoxic section and aerobic section During treatment, part of the effluent that has been fully reacted in the aerobic section needs to be returned to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com