A kind of waste lubricating oil hydrorefining pretreatment method

A technology for hydrotreating pretreatment and waste lubricating oil, applied in hydrotreating process, treating hydrocarbon oil, chemical instruments and methods, etc. The effect of enhancing catalytic active sites, reducing energy consumption for dehydration, and reducing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

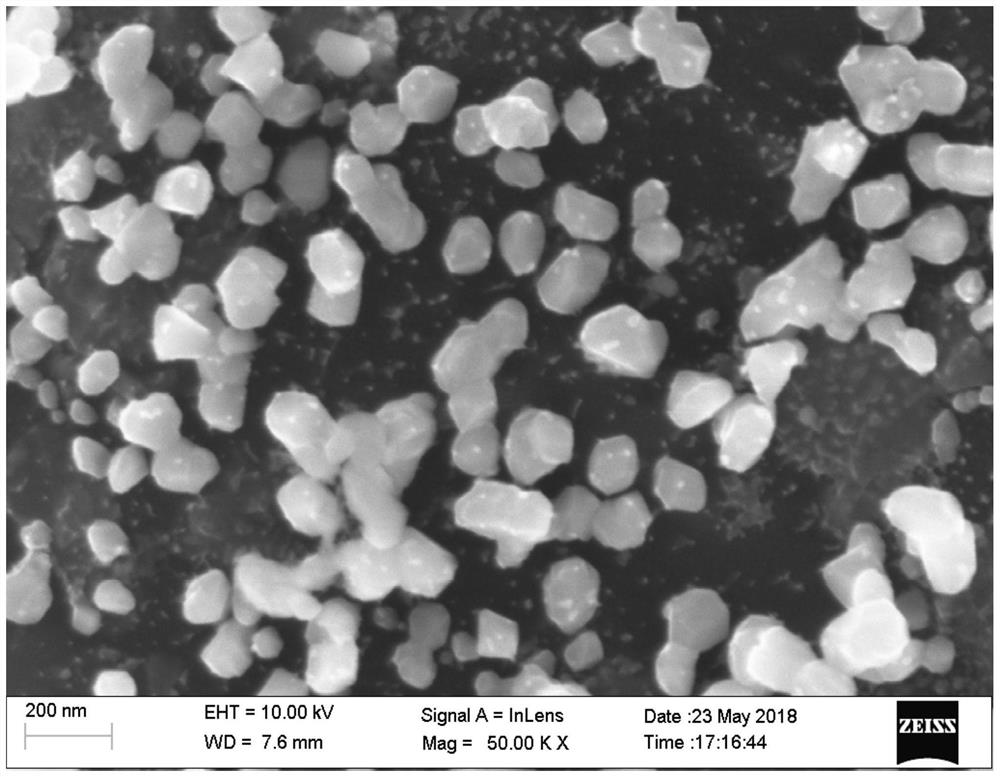

[0036] Microwave pyrolysis catalyst preparation method of the present invention specifically comprises the following steps:

[0037] Step 1, under the condition of isolated air, add A in the ball mill in sequence n B m Components of type metal mixtures, for A n B m Type metal mixture is divided into dry ball milling to obtain catalytic component A. The ball milling conditions are as follows: a number of mixed quartz balls with a diameter of 5mm to 35mm are used for ball milling. In terms of mass parts, the mixed quartz balls include: 30 parts of 5mm quartz balls, 25 parts of 15mm quartz balls, 25 parts of 25mm quartz balls, and 10 parts of 30mm quartz balls Balls and 10 parts of 35mm quartz balls, (20-40): 1, the speed of the ball mill is 120r / min-180r / min, the milling time is 12h-24h, and the protective gas is nitrogen;

[0038] Step 2: Add activated semi-coke powder that meets the particle size requirements after activation into deionized water, the ratio of deionized wa...

Embodiment 1

[0043] The preparation process of the microwave pyrolysis catalyst of the present embodiment is:

[0044] Add 10g of A in the ball mill in sequence n B m Each component of the type metal mixture (A n B m Type metal mixture, containing 2g of CoO, 2g of MoS 2 and 6g of Fe 3 o 4 ), using nitrogen as a protective gas, ball milling at a speed of 120r / min for 12h to prepare catalytic component A. Add 90 g of activated blue charcoal powder with a particle size of less than 76 μm into 450 mL of deionized water, shake at a constant temperature of 40°C for 6 hours at a shaking speed of 60 r / min, and obtain a mixed solution B. Add 10 g of catalytic component A to the mixed solution B, and ultrasonicate at a constant temperature of 40° C. for 2 hours at a frequency of 120 KHz to obtain a mixed solution C. Heat and boil the mixed liquid C until the water in the suspension is evaporated to dryness, and then dry in a vacuum oven for 24 hours to obtain a black solid D, which is the mic...

Embodiment 2

[0046] The preparation process of the microwave pyrolysis catalyst of the present embodiment is:

[0047] Add 10g of A in the ball mill in sequence n B m Each component of the type metal mixture (A n B m Type metal mixture, containing 2g of CoO, 2g of MoS 2 and 6g of Fe 3 o 4 ), using nitrogen as a protection, ball milling at a speed of 120r / min for 12h to prepare catalytic component A. Add 120 g of activated blue carbon powder with a particle size of less than 76 μm into 450 mL of deionized water, and shake at a constant temperature of 40°C for 6 hours at a shaking speed of 60 r / min to obtain a mixed solution B. Add 10 g of catalytic component A to the mixed solution B, and ultrasonicate at a constant temperature of 40° C. for 2 hours at a frequency of 120 KHz to obtain a mixed solution C. Heat and boil the mixed liquid C until the water in the suspension is evaporated to dryness, and then dry in a vacuum oven for 24 hours to obtain a black solid D, which is the microw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com