Ethylene glycol industrial waste water treatment device and method for treating ethylene glycol industrial waste water

A technology for industrial waste water and treatment devices, applied in water/sewage treatment, natural water body treatment, water treatment parameter control, etc. It can solve problems such as high investment and operating costs, unprocessable waste water, clogging of circulating pumps, etc., to ensure normal operation , accurate pH value, and the effect of saving dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

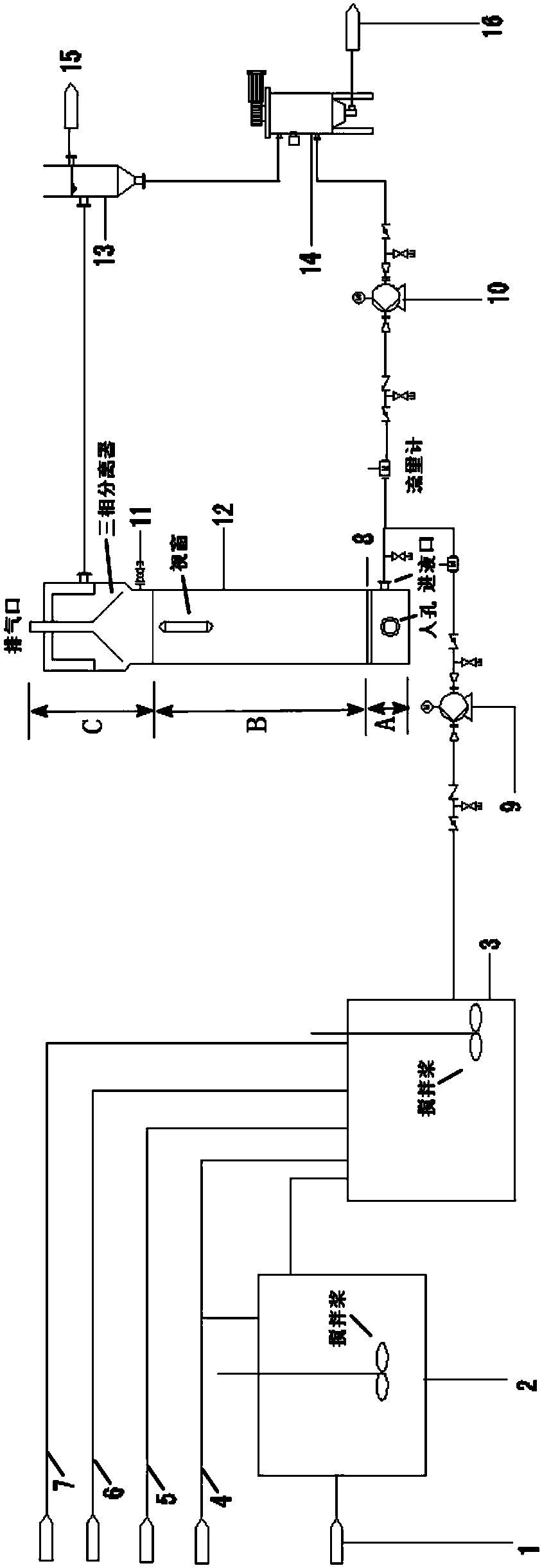

[0098] (1) if figure 1 As shown, the concentration of influent COD is 1800mg / L, NO 3 The concentration of -N is that the flow rate of 2320mg / L is the ethylene glycol industrial waste water 1 of 10t / h in the homogeneous pool 2, by contacting with the lye (concentration is 32%) from alkali tank 4, regulates the ethylene glycol industry The pH value of waste water 1 is 0.1, and the effluent of the homogeneous pool is obtained;

[0099] (2) the effluent of the homogeneous pool obtained by step (1) is in the neutralization pool 3, by contacting with the lye (concentration is 32%) from the alkali tank 4, the pH value of the effluent of the homogeneous pool is adjusted, by contacting with the lye from the alkali tank 4 Methanol (concentration is 99.85%) contacts of methanol tank 5, regulates COD: NO 3 -N mass ratio by urea solution from nitrogen salt tank 6 and KH from phosphorus salt tank 7 2 PO 4 Solution contact, adjust COD:N:P mass ratio, obtain the first waste water, the pH ...

Embodiment 2-3

[0106] According to the method of Example 1, the difference is that the ethylene glycol industrial wastewater treatment is carried out according to the reaction conditions in Table 1.

[0107] According to the method of Example 1, the water quality of the purified wastewater in the pool was measured, and the volume load was calculated. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com