Triazole molecularly imprinted polymeric microspheres and preparation method and application thereof

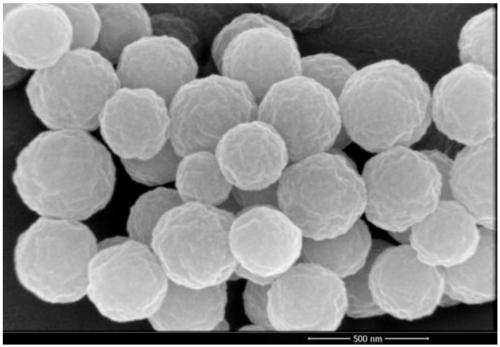

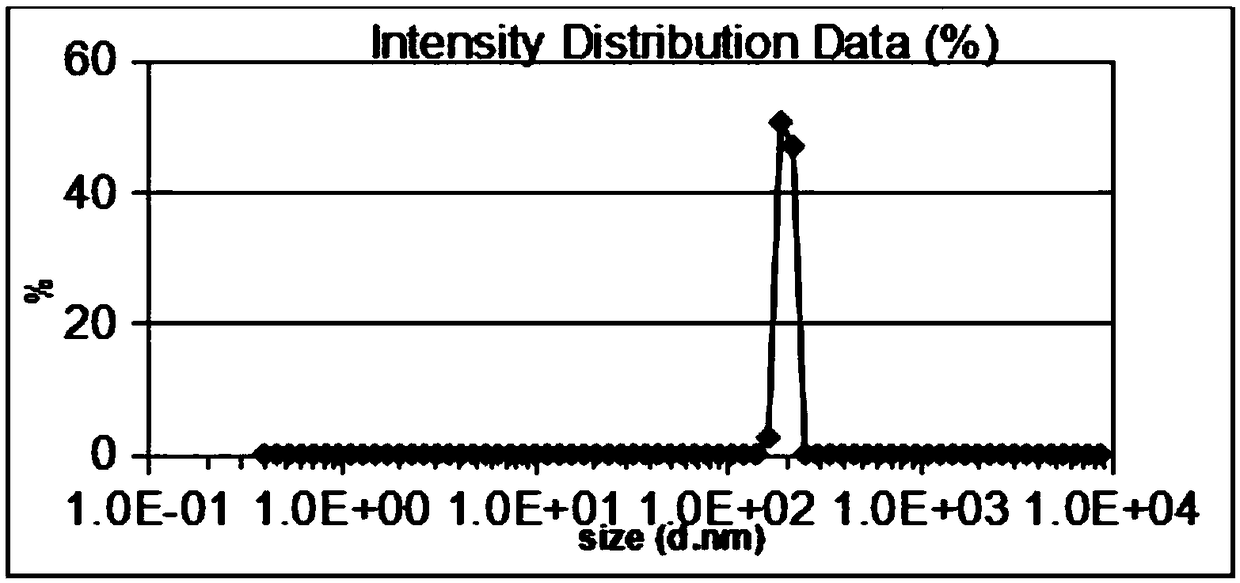

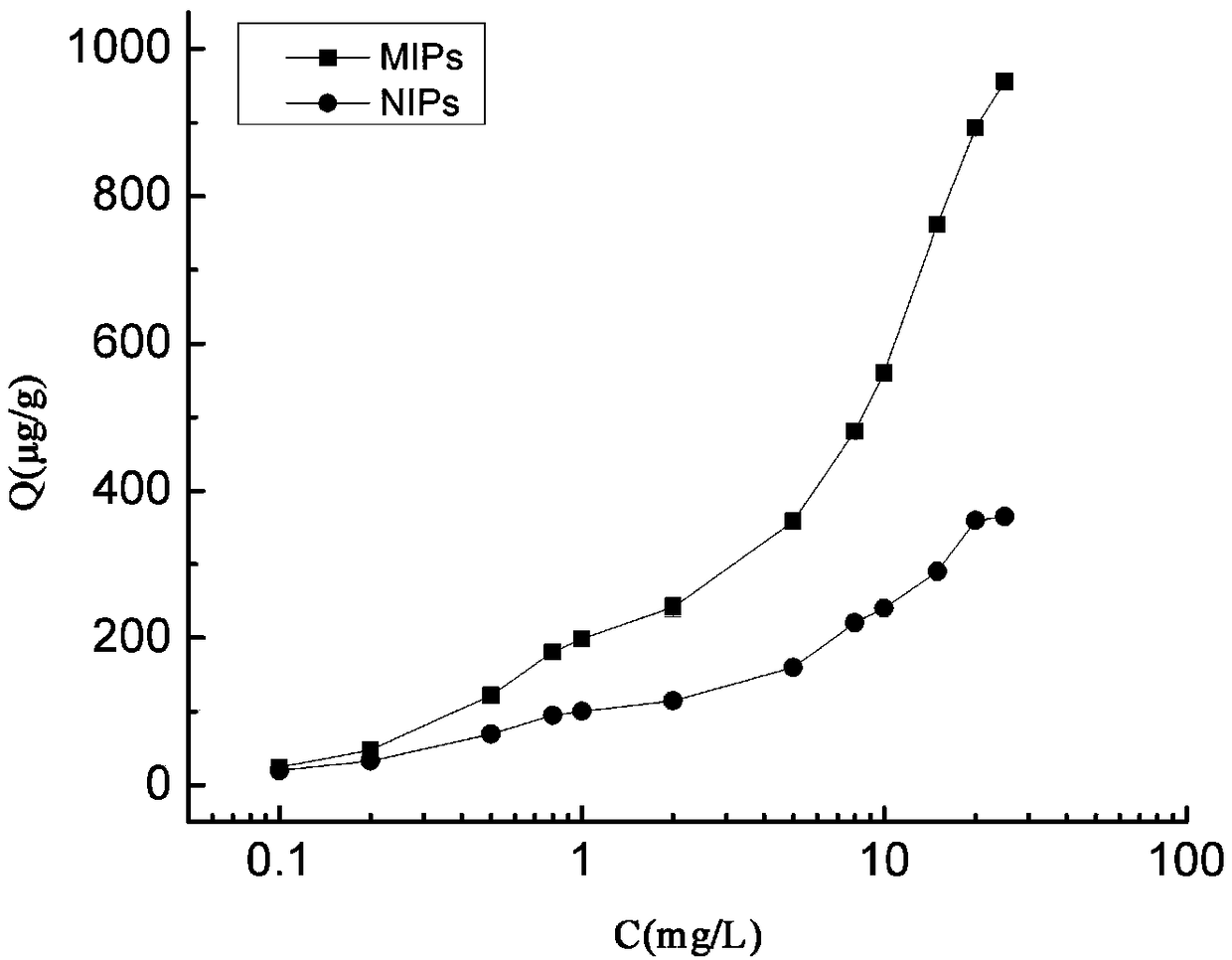

A technology of molecular imprinting and triazoles, which is applied to the preparation of alkali metal compounds, chemical instruments and methods, and test samples, etc., can solve the problems of large polymer particle size and poor specific adsorption effect, and achieve particle size The effect of small size, single particle size distribution, and good specific adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a preparation method of triazole molecularly imprinted polymer microspheres, comprising the following steps:

[0031] 1) Mixing the triazole compound template molecule, the functional monomer and the porogen, and performing self-assembly after ultrasonication in an oxygen-free environment to obtain a self-assembly mixed solution;

[0032] 2) mixing the self-assembly mixed solution obtained in step 1) with an acrylate-based crosslinking agent and an azo-based initiator, and then pre-polymerizing to obtain a pre-polymerization reaction solution; the temperature of the pre-polymerization is 20-40° C.;

[0033] 3) heating the prepolymerized reaction solution obtained in step 2) and performing a polymerization reaction to obtain a polymer; the heating rate is 0.5-1.2°C / min, and the polymerization temperature is 35-60°C;

[0034] 4) eluting the triazole-based compound template molecules in the polymer obtained in step 3) to obtain triazole-based molecul...

Embodiment 1

[0092] Add 0.2 mmol of triazolone, 0.6 mmol of methacrylic acid (MAA) and 50 mL of acetonitrile to a 100 mL borosilicate glass bottle in turn, mix well, and sonicate through N at 25°C. 2 After 10 min, it was placed in a constant temperature gas bath shaker at 25 °C for self-assembly for 10 h, and then 25 mg of azobisisobutyronitrile (AIBN) and 3 mmol of ethylene glycol dimethacrylate (EGDMA) were added, mixed uniformly, and passed through N 2 After 10 min, it was placed in a constant temperature water bath shaker at 25 °C for prepolymerization for 2 h, then the temperature was raised to 40 °C at 0.5 °C / min, and the polymerization was performed for 18 h. After the polymerization, let stand to room temperature, then separate the polymer with a high-speed centrifuge (rotation speed is 10000rpm), pour off the supernatant, put the polymer into a Soxhlet extractor after drying, and use methanol:acetic acid=6:1 (V / V) was repeatedly cycled as eluent to elute template molecules until n...

Embodiment 2

[0104] The MIPs obtained in Example 1 were used as solid-phase extraction fillers, and were applied to spiked tobacco leaves with triazolone, myclobutanil, tebuconazole, hexaconazole, diconazole, propiconazole, tricyclazole, and imine. azole and flusilazole recovery rate detection. The specific process is:

[0105] 1) The tobacco leaf control sample was crushed with a high-speed multifunctional pulverizer for 1 min, passed through a 40-mesh sieve, and then transferred to a constant temperature vacuum drying oven at 50°C to dry to constant weight. Weigh several 1g samples of the above-mentioned dried tobacco leaves and place them in 10mL centrifuge tubes respectively, add 1mL of mixed standard solutions of 9 kinds of triazole fungicides with different concentrations of pesticide residues, and the spiked concentrations are 0.01, 0.05, 0.1, 0.5μg / g, and then vortexed for 5 min to make it fully mixed, left standing at room temperature overnight, and then placed in 50° C. for vac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com