Self-repairing microencapsulated lithium ion battery electrode material and preparation method thereof, lithium ion battery negative electrode and lithium ion battery

A self-repairing microcapsule, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of capacity decay and easy shedding, and achieve the effects of buffer volume expansion, stable chemical properties, and stable cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

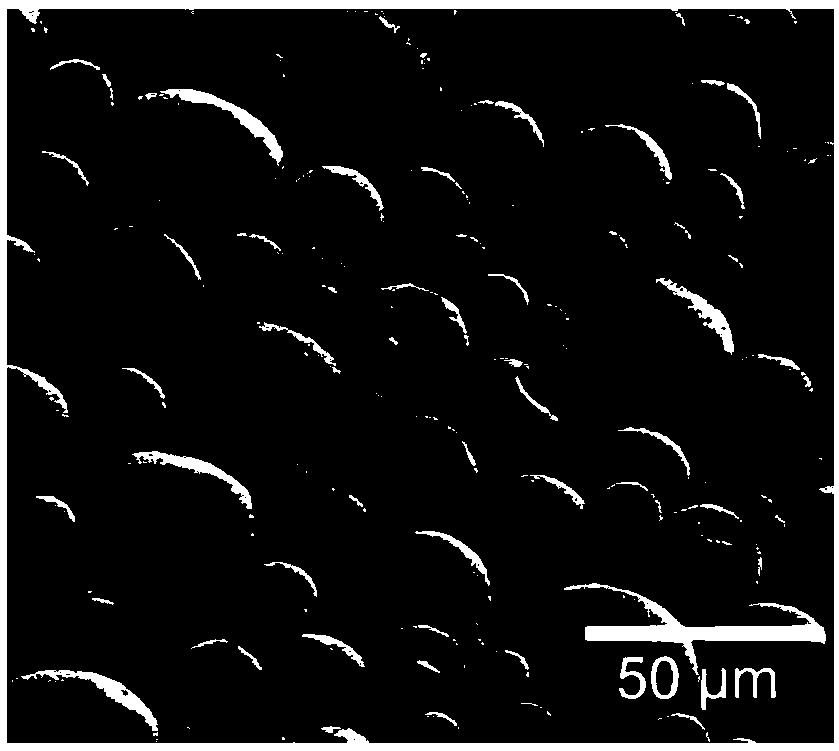

[0042] A preparation method of a self-repairing microcapsule lithium-ion battery electrode material, comprising the following steps:

[0043] 1) Mix 0.1g of liquid alloy particles with 4g of n-hexadecane, and ultrasonically disperse at room temperature for 20 minutes to obtain a mixed solution;

[0044] 2) Add 50mL mixed aqueous solution containing 1.25g urea, 0.25g resorcinol and 0.125g ammonium chloride to the aqueous solution of 2.5wt% polyethylene maleic anhydride copolymer, mechanically stir and mix, add Triethanolamine adjusts the pH to 3.5, stirs until completely dissolved, and mixes; a mixed solution is obtained;

[0045] 3) Put the mixed solution obtained in step 2) into a constant temperature water bath and heat it to 40°C, keep it warm, then add the mixed solution prepared in 1) into the mixed solution obtained in step 2), and mechanically stir at a stirring rate of 800rpm After 0.5h, add 3.1g of formaldehyde solution drop by drop, continue mechanical stirring at 8...

Embodiment 2

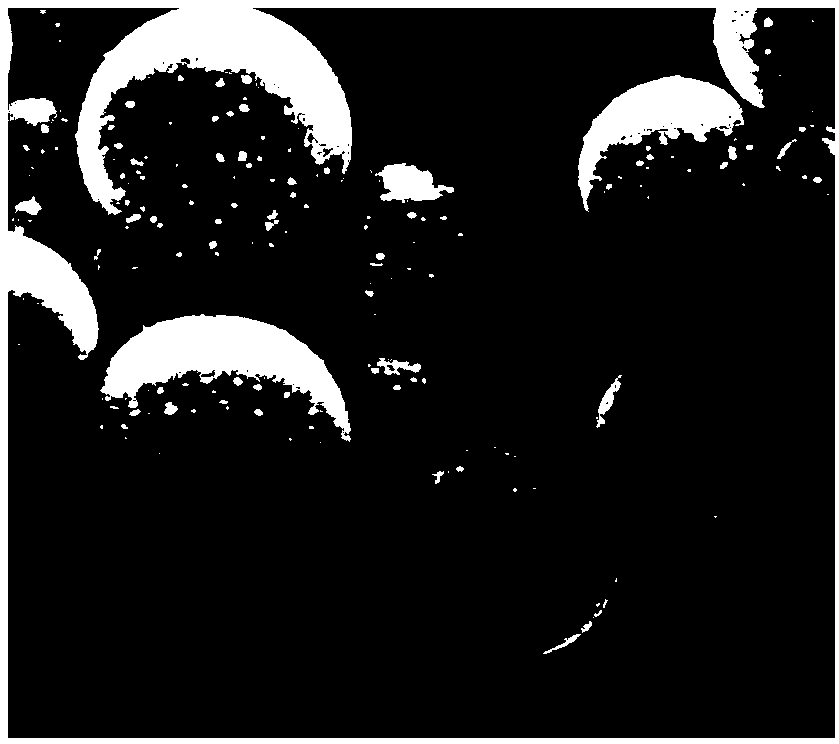

[0051] A method for preparing a carbonized liquid alloy capsule, comprising the following steps:

[0052] 1) Mix 0.2 g of liquid alloy nanoparticles with 4.5 g of n-hexadecane, and ultrasonically disperse at room temperature for 20 minutes to obtain a mixed solution;

[0053] 2) Add 50mL mixed aqueous solution containing 1.25g urea, 0.25g resorcinol and 0.125g ammonium chloride into the aqueous solution of 25mL polyethylene maleic anhydride copolymer with a concentration of 3wt%, mechanically stir and mix, add three Ethanolamine adjusts the pH to 3.5, stirs and mixes, and after all dissolves, a mixed solution is obtained;

[0054] 3) Put the mixed solution obtained in step 2) into a constant temperature water bath and heat it to 45°C, keep it warm, then add the mixed solution prepared in step 2) into the mixed solution obtained in step 2), and mechanically stir at a stirring rate of 850rpm After 0.5h, 3.2g of formaldehyde solution was added dropwise, the stirring rate was 850...

Embodiment 3

[0060] A preparation method of a self-repairing microcapsule lithium-ion battery electrode material, comprising the following steps:

[0061] 1) Mix 0.3g of liquid alloy nanoparticles with 5g of n-hexadecane, and ultrasonically disperse at room temperature for 20min to obtain a mixed solution;

[0062] 2) Add the 50mL mixed aqueous solution containing 1.25g urea, 0.25g resorcinol and 0.125g ammonium chloride into the aqueous solution of 25mL polyethylene maleic anhydride copolymer with a concentration of 3.5wt%, stir mechanically, and pass through three Adjust the pH to 3.5 with ethanolamine, and stir until completely dissolved to obtain a mixed solution;

[0063] 3) Put the mixed solution obtained in step 2) into a constant temperature water bath and heat it to 50°C, keep it warm, then add the mixed solution prepared in 1) into the mixed solution obtained in step 2), and mechanically stir at a stirring rate of 900rpm After 0.5h, add 3.3g of formaldehyde solution drop by drop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com