Method for preparing high-purity tellurium by utilizing copper telluride

A technology of high-purity tellurium and copper telluride, applied in the fields of chemistry and metallurgy, can solve problems such as low recovery rate and complex process of high-purity tellurium, and achieve the effects of easy industrialization, mature production equipment, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

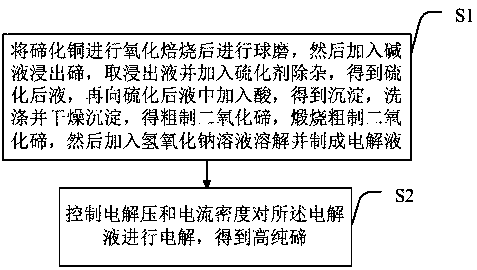

Method used

Image

Examples

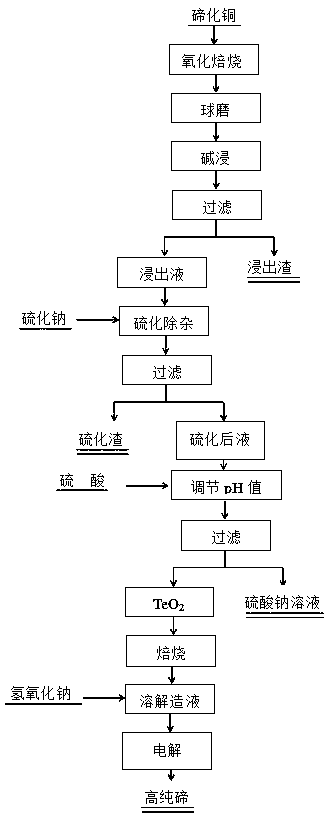

Embodiment 1

[0039] Copper telluride is oxidized and roasted under the condition of blowing air, the temperature is 400°C, and the roasting time is 3h. The obtained roasting is carried out by wet ball milling, and the tellurium is leached by adding alkali and blowing oxygen. The leaching temperature is 60°C, and the leaching time is 3h. After filtration and Wash to obtain tellurium-containing leaching solution and copper-containing leaching residue; add sodium sulfide to the leaching solution to remove impurities, add 5 g of sodium sulfide per liter of leaching solution, vulcanize at 70°C, and vulcanize for 2 hours; add sulfuric acid to the obtained vulcanized solution to adjust pH 5-6 to obtain Tellurium dioxide is precipitated, stirred and washed by ultrasonic radiation, and then dried to obtain crude tellurium dioxide; calcining crude tellurium dioxide to remove selenium, controlling the calcination temperature at 500°C and time for 3h; adding sodium hydroxide to dissolve the calcined tel...

Embodiment 2

[0041]Copper telluride is oxidized and roasted under the condition of oxygen blowing, the temperature is 450°C, and the roasting time is 2h. The obtained roasting is carried out by wet ball milling, and the tellurium is leached by adding alkali and hydrogen peroxide. The leaching temperature is 50°C, and the leaching time is 4h. After filtration and Wash to obtain tellurium-containing leaching solution and copper-containing leaching slag; add sodium sulfide to the leaching solution to remove impurities, add 8 g of sodium sulfide per liter of leaching solution, vulcanize at 60°C, and vulcanize for 2 hours; add sulfuric acid to the obtained vulcanized solution to adjust the pH to 5-6 to obtain Tellurium dioxide is precipitated, stirred and washed by ultrasonic radiation, and then dried to obtain crude tellurium dioxide; calcining crude tellurium dioxide to remove selenium, controlling the calcination temperature at 550°C and time for 2h; adding sodium hydroxide to dissolve the cal...

Embodiment 3

[0043] The copper telluride is roasted with sodium nitrate under the condition of blowing air, the temperature is 500°C, the roasting time is 2h, and the obtained roasting is carried out by wet ball milling, and the tellurium is leached by adding alkali and sodium chlorate, the leaching temperature is 70°C, and the leaching time is 3h , after filtration and washing, to obtain tellurium-containing leaching solution and copper-containing leaching slag; adding sodium sulfide to the leaching solution to remove impurities, the amount of hydrogen sulfide per liter of leaching solution was 0.3 liters, the sulfidation temperature was 60 ° C, and the sulfidation time was 2 hours; Adjust the pH to 5-6 to obtain tellurium dioxide precipitates, wash with mechanical stirring, and then dry to obtain crude tellurium dioxide; calcining crude tellurium dioxide to remove selenium, control the calcination temperature at 500°C and time for 3h; add sodium hydroxide to dissolve and calcined telluriu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com