Photocatalyst supported micro-nano-composite fiber material loaded and preparation method thereof

A photocatalyst, micro-nano composite technology, applied in chemical instruments and methods, physical/chemical process catalysts, fiber types, etc., can solve the problems of small specific surface area, poor pollutant adsorption capacity, etc., achieve good flexibility and avoid secondary Pollution, Ease of Recycling Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

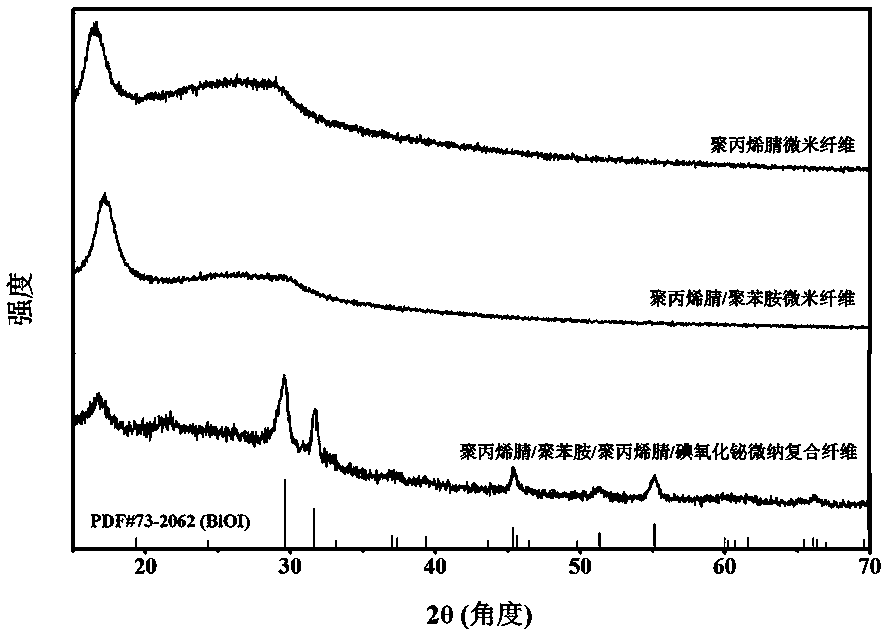

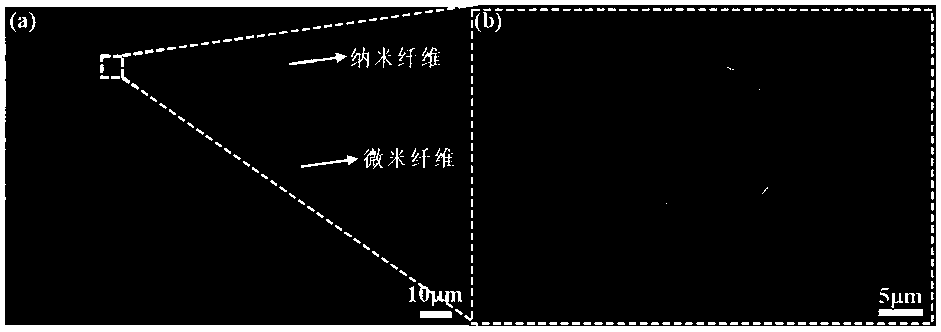

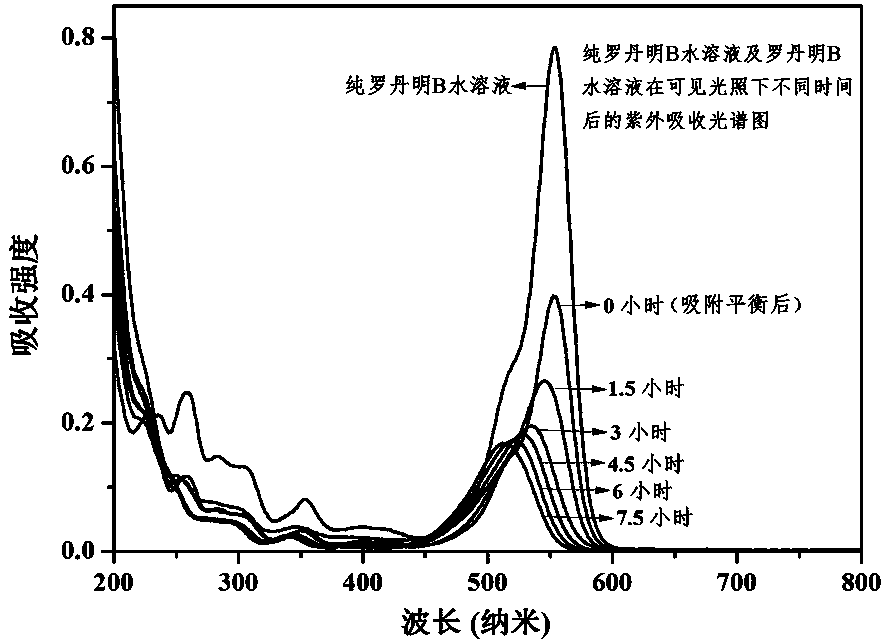

[0025] This embodiment provides a method for preparing a photocatalyst-loaded micro-nano composite fiber material, as follows:

[0026] Preparation of polyacrylonitrile micron fibers: Pour 10 g of polyacrylonitrile, 40 mL of dimethyl sulfoxide and 0.8 mL of water into a three-necked flask, and stir at room temperature to make it fully swell. Then heat and stir at 40° C. for 3 hours to fully dissolve the polyacrylonitrile, and put it into a vacuum drying oven at 60° C. for vacuum degassing treatment. Take the above spinning solution, and prepare polyacrylonitrile micron fiber through wet spinning device, spinning process: spinning temperature: 40 ℃; pressure: 0.2 MPa; inner diameter of spinning hole: 0.5 mm; coagulation bath: N,N- The mixture of dimethylformamide and water (Vol DMF : Vol H2O = 3:1). Finally, heat stretching treatment at 150 °C is carried out.

[0027] In-situ polymerization of conductive polymer polyaniline on the surface of polyacrylonitrile microfibers: ...

Embodiment 2

[0035] Preparation of polyimide micron fibers: 3.204 g of 4,4’-diaminodiphenyl ether and 0.433 g of p-phenylenediamine were poured into a three-neck flask, placed in an ice-water bath (0 °C), and nitrogen gas was passed for 2 h. Then, 4.450 g of pyromellitic dianhydride was added into the three-necked flask three times at equal intervals of half an hour. After reacting for 2 hours, 1.021 g of acetic anhydride and 0.791 g of pyridine were slowly added dropwise. After reacting for 2 h, the mixed solution was subjected to vacuum degassing treatment in a vacuum oven at 60 °C, and it was used as the spinning solution. The above spinning solution was taken, and polyimide fibers were prepared by a self-made wet spinning device. The spinning process: spinning temperature: 50°C; pressure: 0.2 MPa; inner diameter of the spinning hole: 0.5 mm; Water mixture (Vol methanol : Vol H2O =7:3). Finally, heat stretching treatment at 300 °C is carried out.

[0036] In-situ polymerization of ...

Embodiment 3

[0042] Preparation of polyvinyl alcohol microfibers: Pour 10 g of PVA, 39 mL of dimethyl sulfoxide and 13 mL of water into a three-neck flask, and stir continuously at 90 °C for 4 h until completely dissolved to obtain a uniform and transparent PVA solution, and then Let stand for 2 h to defoam. The above spinning solution was taken, and polyvinyl alcohol fibers were prepared by a self-made wet spinning device. The spinning process: spinning temperature: 50 °C; pressure: 0.2 MPa; inner diameter of spinning holes: 0.5 mm; coagulation bath: methanol. Finally, heat stretching treatment at 200 °C is carried out.

[0043] In-situ polymerization of conductive polymer polyaniline on the surface of polyvinyl alcohol microfibers: put a certain length of polyvinyl alcohol microfibers into a mixture of aniline (1.86 g), polyvinylpyrrolidone (2.08 g) and 40 mL of hydrochloric acid, 30 Minutes later, a mixture of ammonium persulfate (2.28 g) and 20 mL of hydrochloric acid was added, and r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com