Cell culture substratum, method for producing cell-containing material, method for producing cell culture substratum, method for observing cells, and cell culture substratum maintenance liquid

By forming multiple concave and convex structures on the cell culture substrate and coating them with inorganic materials, combined with proteins, the cell adhesion rate and survival rate are improved, and the low adhesion rate, survival rate, and insufficient thermal stability of polystyrene cell culture dishes are solved. issues, achieving durability and recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0107] (Preparation method of cell contents)

[0108] The method for producing a cell content according to the present embodiment includes a step of applying cells to a concavo-convex structure in a cell culture substrate and culturing them. By applying cells to the concavo-convex structure, cell culture can be highly activated, and cell contents such as cell tissue or living tissue having good adhesion to the matrix can be produced.

[0109] In the preparation method of the cell content, cells are cultured using a cell culture substrate made of polystyrene, and the culture time at which the density of the cells is 90% of the culture surface of the cell culture substrate made of polystyrene is defined as 1T. In some cases, it is preferable to culture cells for a culture time of 1 / 2T to 2 / 3T using the cell culture substrate of this embodiment. For example, when the culture time for 90% of the culture surface of a cell culture substrate made of polystyrene is 24 hours, by using...

Embodiment 1

[0121] Both surfaces of the quartz glass substrate made of silica were polished using a double-side grinder (manufactured by Hamai Sangyo Co., Ltd., 4-way grinding disc). In the grinding process, zirconia-based alumina (AZ) powder manufactured by Heisei Sankei Co., Ltd. 2 , Platen rotation speed 20 ~ 50rpm implementation. Both surfaces of the polished quartz glass substrate were polished using a double-side polisher (manufactured by Hamai Sangyo Co., Ltd., 4-way polishing disc). In the polishing process, a polyurethane foam pad is used as a polishing pad, and MIREK E manufactured by Mitsui Metal Mining Co., Ltd. 2 , Platen rotation speed 20 ~ 50rpm implementation. Accordingly, a cell culture substrate composed of a silica substrate was prepared.

Embodiment 2

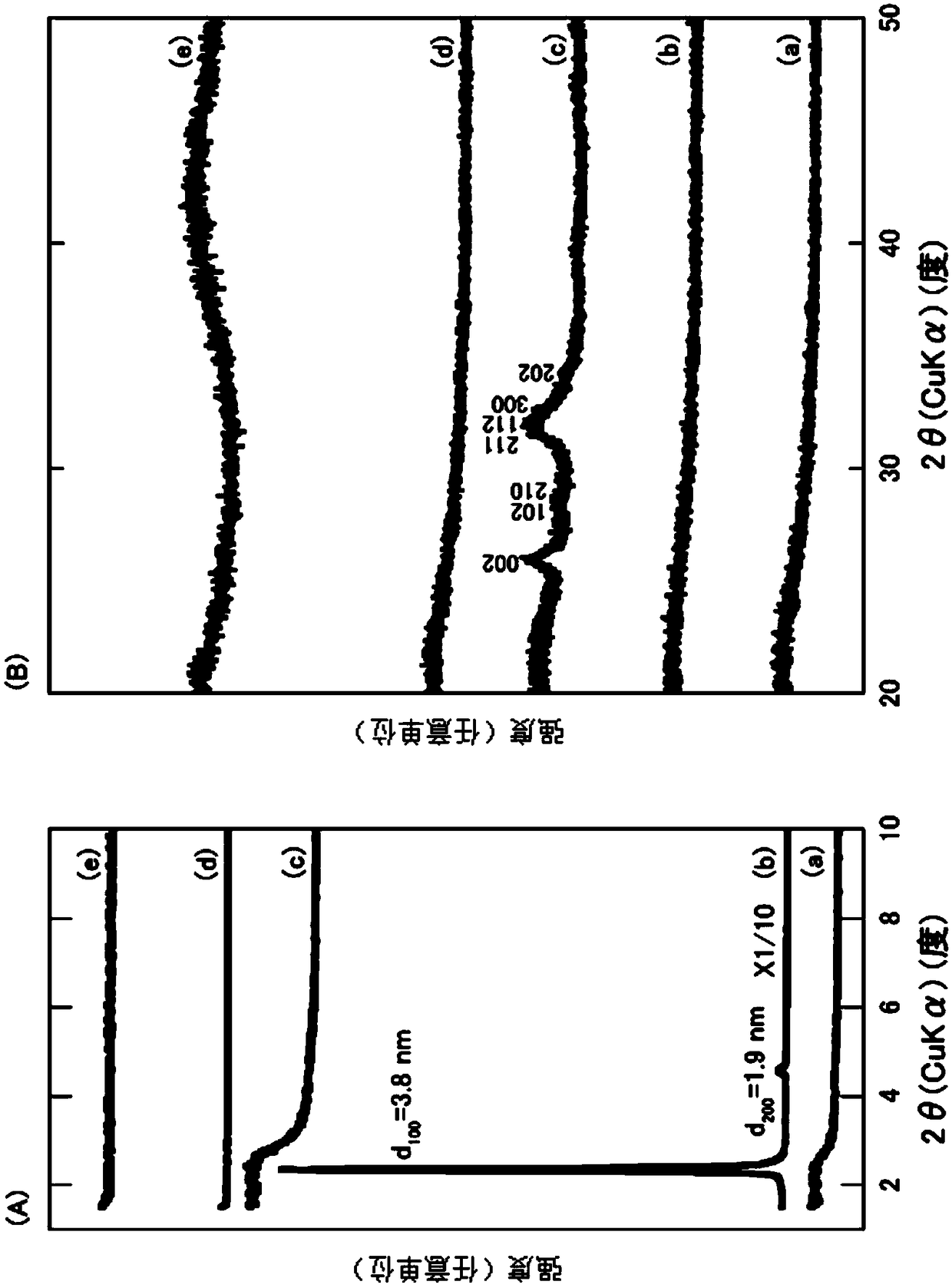

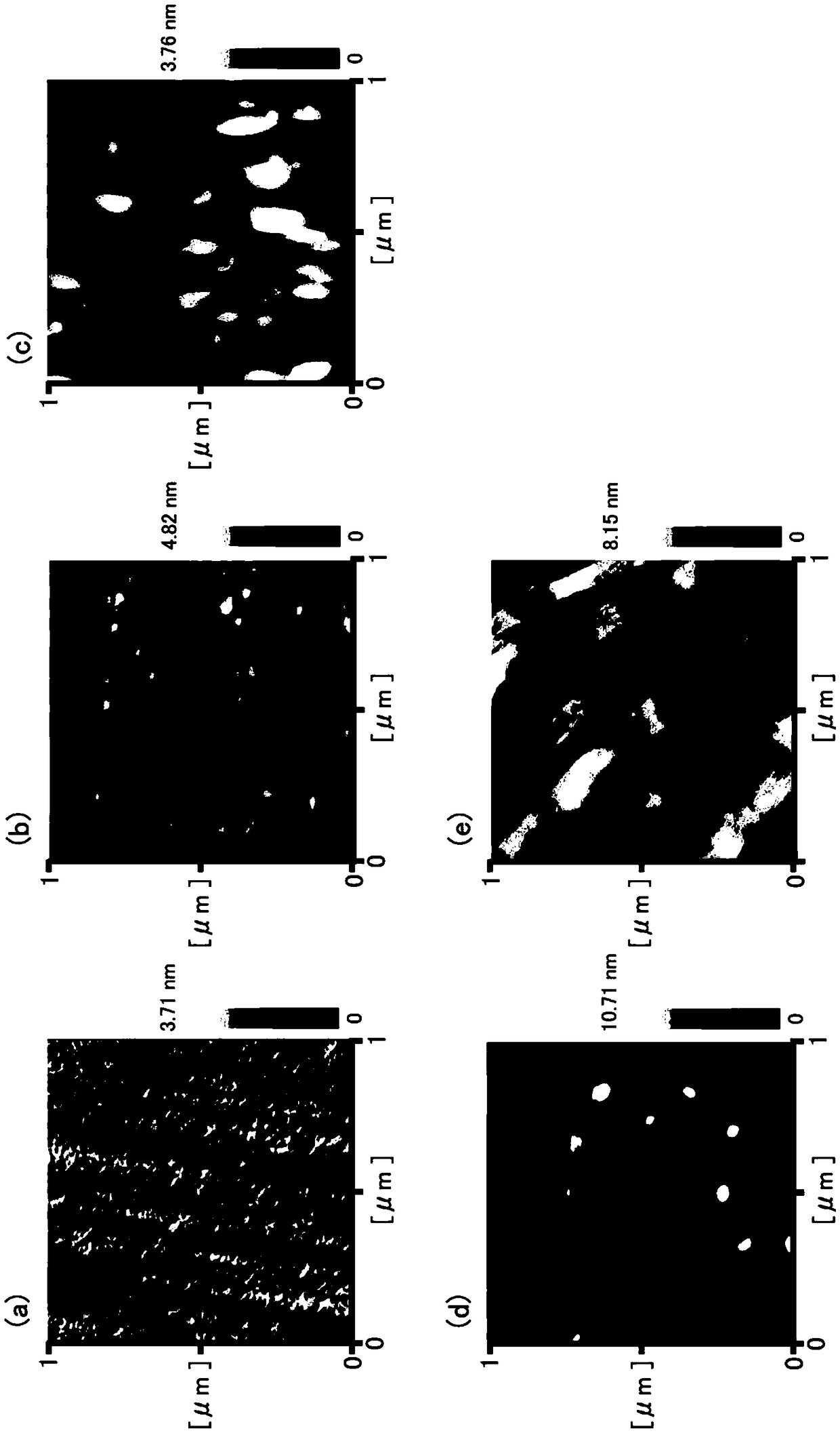

[0123] (Preparation method of a cell culture substrate in which a silica substrate is coated with a porous silica film)

[0124] Add 524 mg of cetyltrimethylammonium chloride (CTAC) to 1.4 ml of water, stir until dispersed, and obtain solution A. Then, 0.472 ml of water and 0.1 ml of 0.1N-HCl were added to 1.94 ml of orthomethyl silicate (TMOS), and stirred at 30° C. for 60 minutes to obtain a solution B. Solution A and solution B were mixed so that the molar ratio of TMOS / CTAC was 8, and 0.1 ml of 1N-HCl was further added to obtain mixed solution C. After the mixture C was stirred at room temperature (20° C.) for 15 minutes, spin coating was performed at 6000 rpm for 10 seconds on the silica substrate (12.5 mm × 25 mm) of Example 1 having a concavo-convex shape on the culture surface. . The silicon dioxide substrate coated with the mixed solution C was heated at 60° C. for 18 hours to form a CTAC / TMOS composite film. In addition, the silica substrate on which the composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com