A kind of concrete template material and preparation method thereof

A technology of concrete formwork and polymerized monomers, which is applied in fiber processing, textiles and papermaking, and can solve problems such as poor flame retardancy, many seams, and narrow format

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

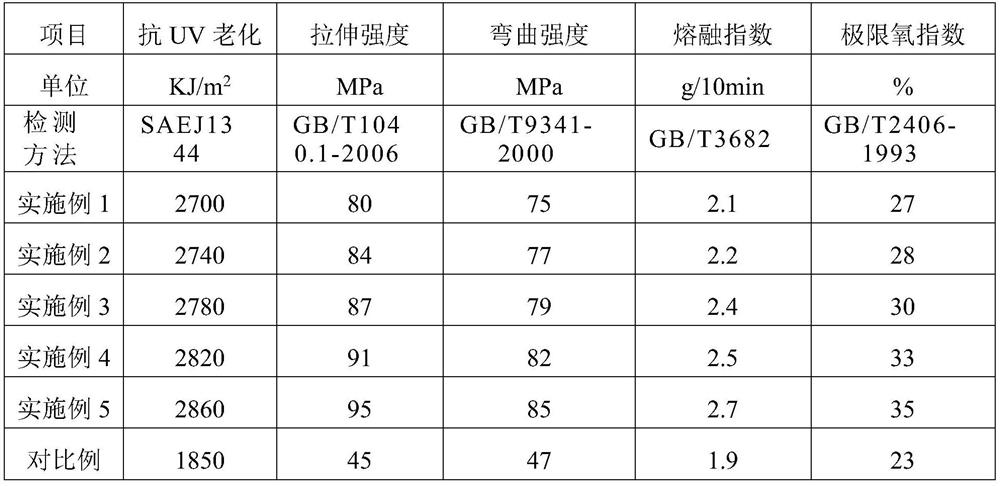

Examples

Embodiment 1

[0030] A preparation method for concrete formwork material, comprising the steps of:

[0031] ⅠAdd 13.3g of 2,7-dibromo-9,9-difluorofluorene, 10g of Plinberry, 3g of cesium carbonate, and 2g of tetrachlorobenzoquinone to a three-necked flask connected with a water separator, and then add dimethyl 50g of sulfoxide and 30g of toluene, heated the reaction system to 130°C, stirred and reacted for 4 hours under nitrogen protection, removed the water and toluene generated during the reaction through a water separator, and slowly raised the reaction temperature to 140°C after removing all the water. Continue to stir and react for 8 hours. After the reaction finishes, the reaction system is cooled to room temperature and precipitated in water. The precipitated polymer is washed 4 times with dichloromethane, then washed 3 times with isopropanol, and the solvent is removed by rotary evaporation to obtain a polymer based on Fluorine-containing fluorene benzoxazole condensation polymer; ...

Embodiment 2

[0037] A preparation method for concrete formwork material, comprising the steps of:

[0038] ⅠAdd 13.3g of 2,7-dibromo-9,9-difluorofluorene, 10g of Plinberry, 4g of sodium carbonate, and 2.5g of 1,4-naphthoquinone into a three-necked flask connected with a water separator, and then Add 65g of N,N-dimethylformamide and 35g of toluene, heat the reaction system to 132°C, stir the reaction for 4.5 hours under the protection of helium, remove the water and toluene generated during the reaction through a water separator, and remove all the water Slowly raise the reaction temperature to 142°C, continue to stir and react for 8.5 hours, after the reaction, cool the reaction system to room temperature, precipitate in water, wash the precipitated polymer with dichloromethane for 5 times, and then wash with isopropanol for 4 times , and the solvent is removed by rotary evaporation to obtain a polycondensate based on fluorine-containing fluorene benzoxazole;

[0039] ⅡIn a three-neck fla...

Embodiment 3

[0044] A preparation method for concrete formwork material, comprising the steps of:

[0045] ⅠAdd 13.3g of 2,7-dibromo-9,9-difluorofluorene, 10g of Plinberry, 4g of potassium carbonate, and 3g of chloranil to a three-necked flask connected with a water separator, and then add N- 75g of methylpyrrolidone and 40g of toluene, heat the reaction system to 135°C, stir the reaction for 5 hours under the protection of neon gas, remove the water and toluene generated during the reaction through a water separator, and slowly raise the reaction temperature to 145°C after removing all the water ℃, continue to stir the reaction for 9 hours, after the reaction, the reaction system is cooled to room temperature, precipitated in water, the precipitated polymer is washed 5 times with dichloromethane, and then washed 4 times with isopropanol, and then the solvent is removed by rotary evaporation. Obtain a polycondensate based on fluorine-containing fluorene benzoxazole;

[0046] ⅡIn a three-n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com